Content last revised on November 21, 2025

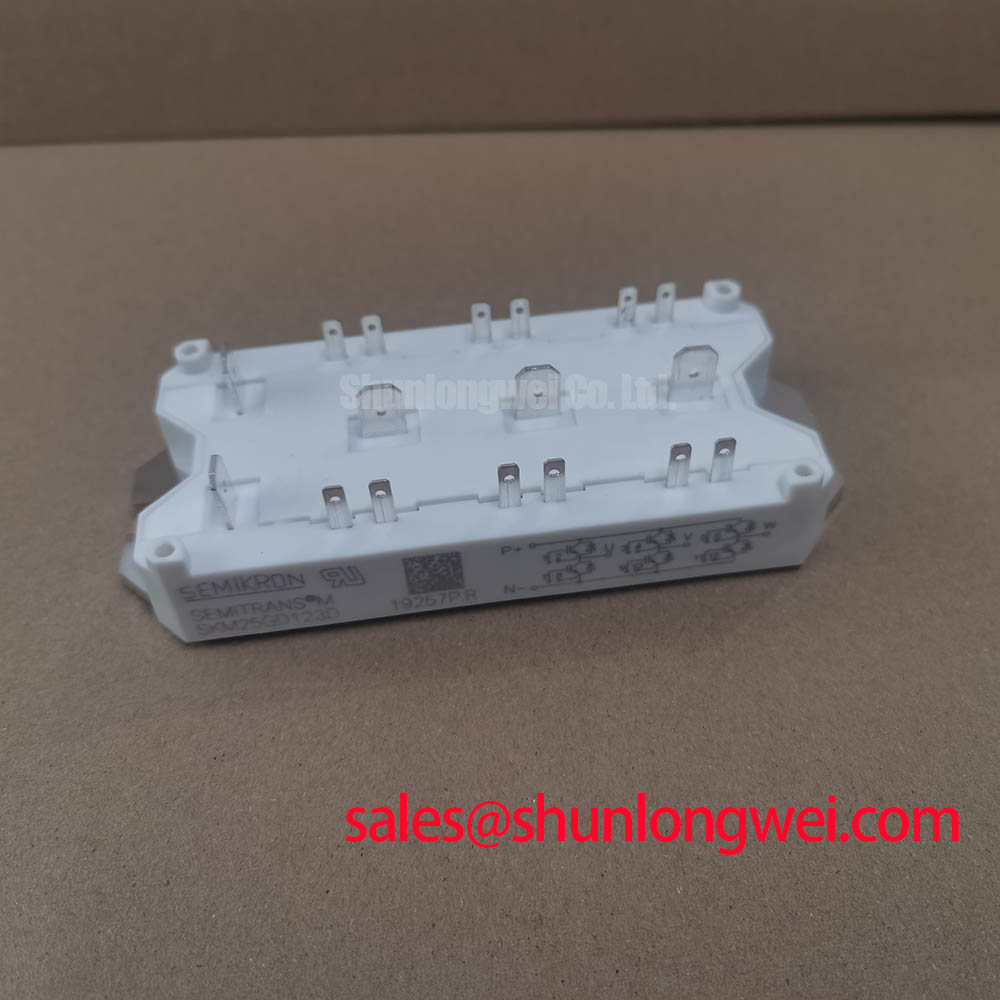

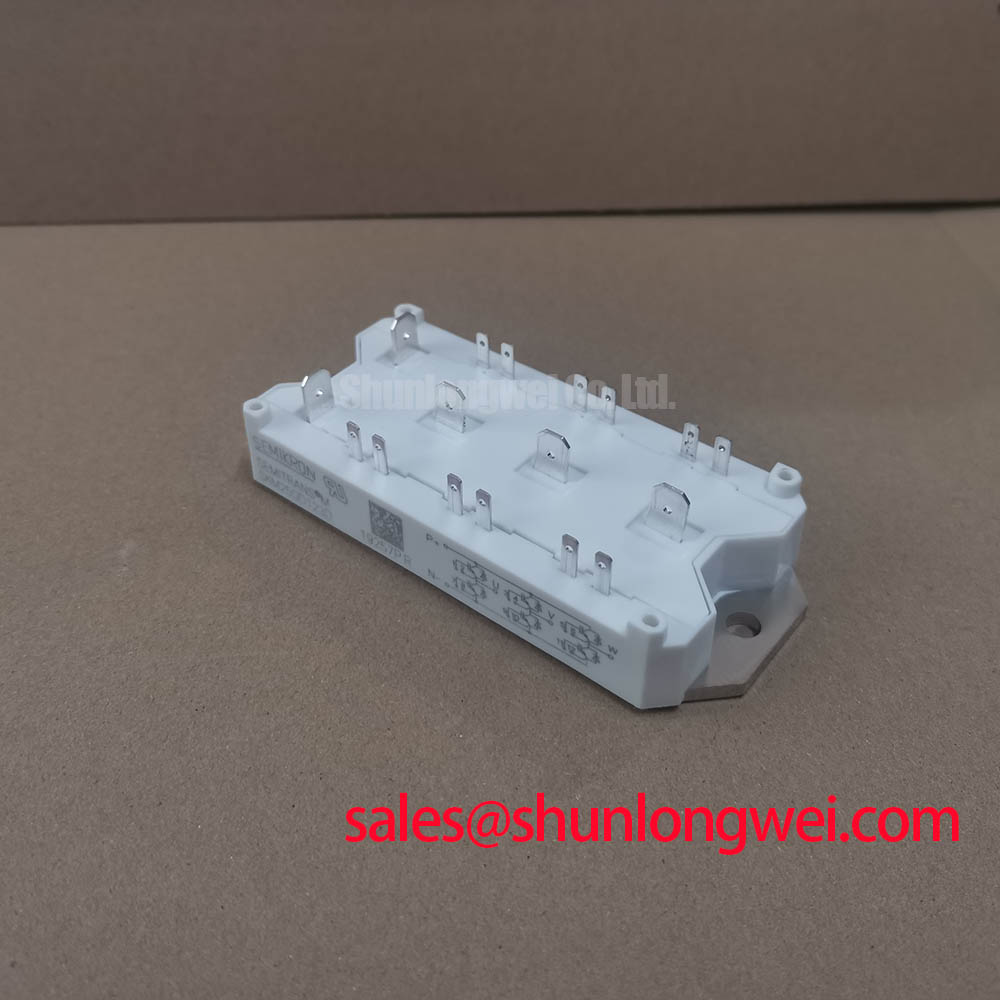

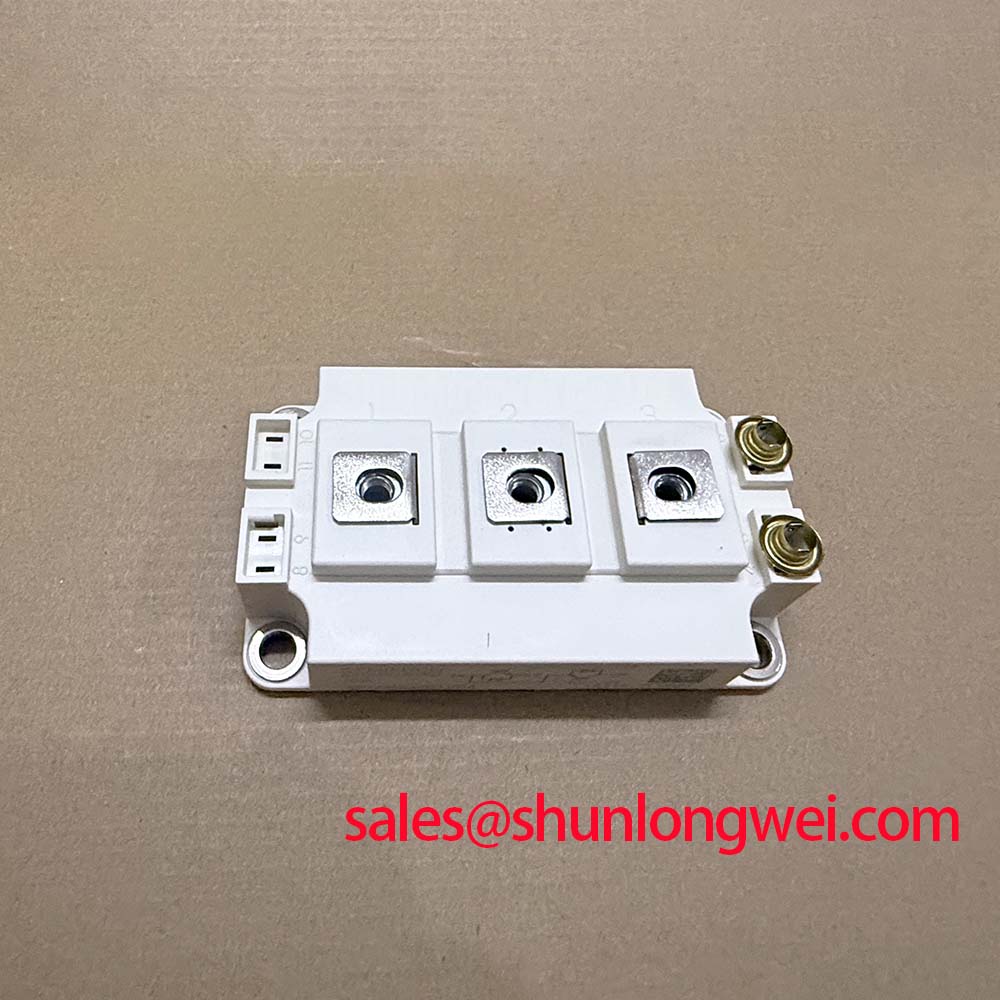

SKM25GD123D: A Technical Analysis of the SEMITRANS 2 Dual IGBT Module

Engineered for Reliability in Demanding Power Conversion Systems

The SKM25GD123D is a SEMITRANS 2 dual IGBT module designed for robust performance in industrial power conversion applications. This component delivers a precise balance of conduction and switching efficiency, underpinned by its 1200V collector-emitter voltage and 25A continuous collector current rating. Key engineering benefits include enhanced thermal stability through its isolated copper baseplate and the proven reliability of CAL (Controlled Axial Lifetime) freewheeling diodes. This module directly addresses the need for durable and efficient power stages in systems like small- to mid-sized motor drives. For systems demanding higher power output while maintaining the same 1200V blocking voltage, the related SKM75GD123D offers a higher current rating in a compatible package family.

Key Parameter Overview

Decoding the Specs for System-Level Performance

The technical specifications of the SKM25GD123D are foundational to its performance in high-frequency and high-voltage environments. The parameters below detail its switching behavior, thermal characteristics, and electrical limits, providing the necessary data for precise system design and simulation.

| Absolute Maximum Ratings (Tcase = 25°C unless otherwise specified) | ||

|---|---|---|

| Parameter | Symbol | Value |

| Collector-Emitter Voltage | VCES | 1200 V |

| Continuous Collector Current (Tcase = 25°C) | IC | 25 A |

| Continuous Collector Current (Tcase = 80°C) | IC | 15 A |

| Total Power Dissipation per IGBT | Ptot | 145 W |

| Operating Junction Temperature | Tj | -40 to +150 °C |

| IGBT Characteristics (Tj = 125°C unless otherwise specified) | ||

| Parameter | Symbol | Typical Value |

| Collector-Emitter Saturation Voltage (IC = 15A, VGE = 15V) | VCE(sat) | 3.1 V |

| Gate Threshold Voltage | VGE(th) | 5.5 V |

| Diode Characteristics (Tj = 125°C unless otherwise specified) | ||

| Parameter | Symbol | Typical Value |

| Forward Voltage (IF = 15A) | VF | 2.4 V |

| Thermal Characteristics | ||

| Parameter | Symbol | Max Value |

| Thermal Resistance, Junction-to-Case (per IGBT) | Rth(j-c) | 0.86 K/W |

| Thermal Resistance, Junction-to-Case (per Diode) | Rth(j-c) | 1.3 K/W |

Note: The parameters listed are derived from the official datasheet and represent key performance indicators. For comprehensive electrical and thermal characteristics, performance curves, and mechanical drawings, please refer to the manufacturer's documentation.

Download the SKM25GD123D datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving Reliable Control in Small Motor Drives and Power Supplies

The SKM25GD123D is optimized for power conversion stages where reliability and thermal management are critical. Its dual (half-bridge) configuration makes it a natural fit for the inverters used in Variable Frequency Drives (VFDs) for AC motors, servo drives, and switched-mode power supplies (SMPS).

A primary engineering challenge in these applications is managing switching and conduction losses to maintain high efficiency and prevent thermal runaway. The SKM25GD123D's typical VCE(sat) of 3.1V at nominal operating conditions dictates its conduction losses. Think of VCE(sat) as the electrical "friction" the device exhibits when it's fully on; a lower value means less energy is wasted as heat. This allows for smaller heatsinks and more compact system designs. Furthermore, the inclusion of fast and soft inverse CAL diodes minimizes voltage overshoots and electromagnetic interference (EMI) during switching, simplifying the design of snubber circuits and improving overall system robustness. This module is particularly effective in applications operating at switching frequencies up to 15 kHz.

Technical Deep Dive

An Analysis of the Trench Gate IGBT and CAL Diode Technology

The performance of the SKM25GD123D is rooted in its internal component technologies. The module utilizes N-channel, homogeneous silicon IGBTs, which provide a dependable and well-characterized switching performance. These are paired with CAL (Controlled Axial Lifetime) freewheeling diodes, a key feature for modern power systems.

The "soft" recovery characteristic of a CAL diode is crucial. During the transition from conducting to blocking state, a "hard" recovery diode can cause abrupt current changes, leading to significant voltage spikes and EMI. The soft recovery of the CAL diode ensures a smoother transition, akin to a car's suspension smoothing out a bumpy road. This controlled behavior reduces stress on the entire system, lowers EMI generation, and can decrease the need for extensive filtering components, ultimately saving board space and cost. The module's construction, featuring an isolated copper baseplate with Direct Copper Bonding (DCB) technology, ensures efficient heat transfer from the silicon die to the heatsink, a cornerstone of long-term operational reliability.

Frequently Asked Questions

Engineering Questions on Implementation and Performance

What is the primary benefit of the module's VCE(sat) of 3.1V at 125°C?

A VCE(sat) of 3.1V under nominal load and at operating temperature directly translates to lower conduction losses. This is critical for overall system efficiency, as less power is dissipated as heat within the module. For design engineers, this means a reduced thermal management requirement, potentially allowing for a smaller, more cost-effective heatsink and improving the system's power density.

How does the soft recovery of the CAL freewheeling diode impact system design?

The soft recovery characteristic significantly reduces voltage overshoot and ringing during diode turn-off. This minimizes electromagnetic interference (EMI), which helps systems meet regulatory standards like IEC 61800-3. It also reduces the electrical stress on the IGBTs and other components, improving overall system reliability and potentially reducing the complexity of required Snubber Circuit designs.

What is the function of the isolated copper baseplate using DCB technology?

The Direct Copper Bonding (DCB) substrate provides excellent electrical isolation (rated at 2500V) while maintaining a low thermal resistance path. This ensures that heat generated by the IGBT and diode chips can be efficiently transferred to an external heatsink, keeping the junction temperatures within safe operating limits. This is fundamental to achieving the module's specified power ratings and ensuring long-term operational reliability.

For detailed application notes and design support, please consult our technical resources or contact our engineering team to discuss your specific power conversion requirements.