Content last revised on January 17, 2026

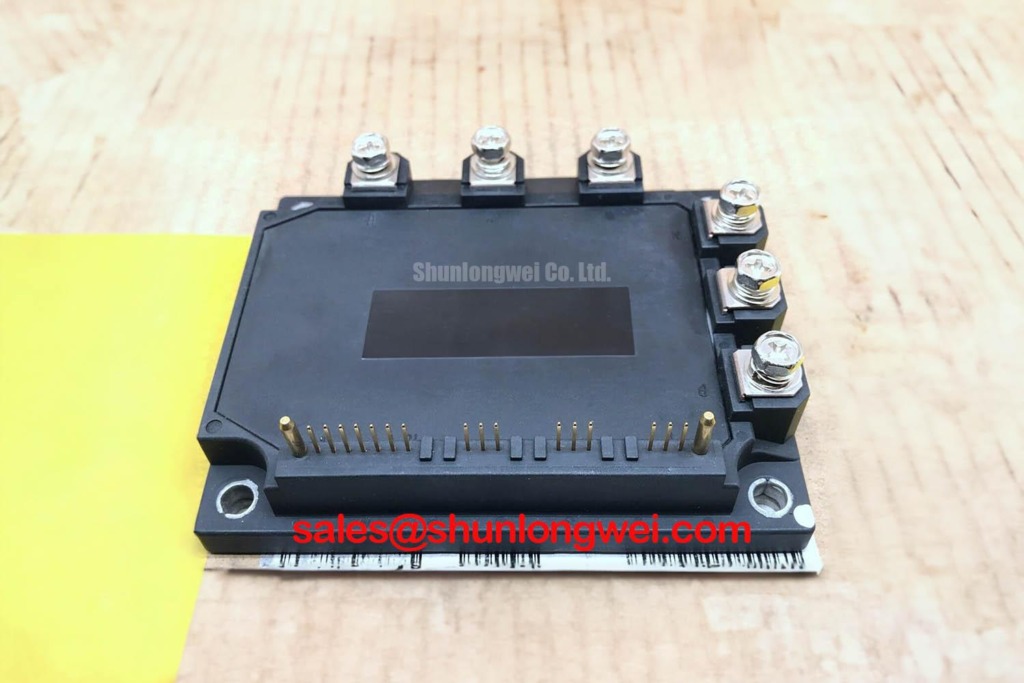

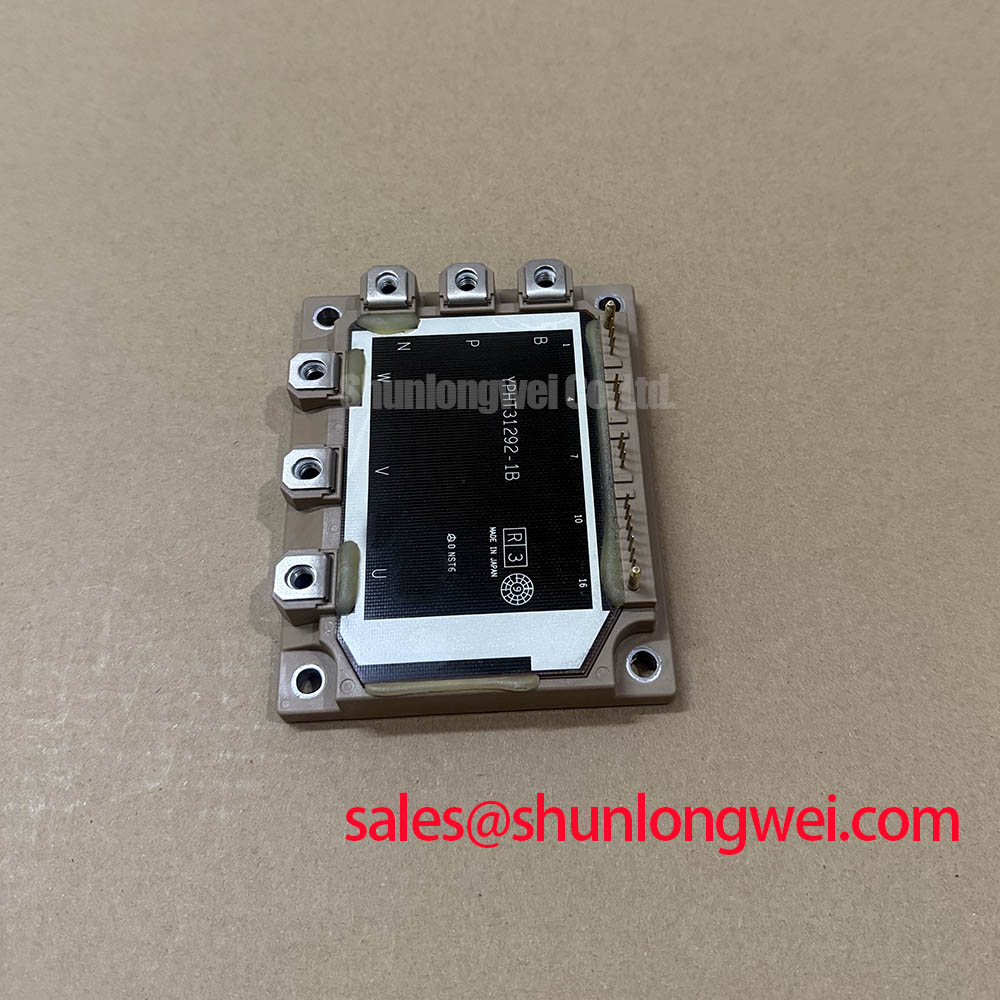

Fuji 6MBP100RA060 | High-Integration 600V PIM for Motor Control

The Fuji Electric 6MBP100RA060 is an expertly engineered Power Integrated Module (PIM) designed to streamline the development of compact and reliable motor drives. By co-packaging a three-phase converter, a brake chopper, and a three-phase inverter into a single, thermally efficient unit, this module addresses the core challenges of system integration, component count reduction, and manufacturing simplification. It stands as a robust solution for power conversion systems up to approximately 7.5 kW.

Technical Deep Dive: The PIM Advantage

The strategic value of the 6MBP100RA060 lies in its highly integrated architecture. This design philosophy delivers tangible engineering benefits that go beyond a simple reduction in footprint.

- System-Level Simplification: Integrating the rectifier, brake, and inverter stages into one module drastically reduces the number of power connections, minimizes bus bar complexity, and simplifies the overall PCB layout. This translates directly to shorter design cycles and lower assembly costs.

- Enhanced Reliability: By minimizing external connections and solder joints, the PIM architecture inherently reduces potential points of failure. The controlled internal environment also leads to lower parasitic inductance compared to discrete solutions, which mitigates voltage overshoot during high-speed switching events and improves electromagnetic compatibility (EMC).

- Consolidated Thermal Management: With all major power stages on a single insulated metal substrate, heat dissipation is centralized. This allows for a simpler, more effective heatsink design, ensuring all semiconductor components operate within their specified Safe Operating Area (SOA) under demanding load conditions.

Application Scenarios and Engineering Value

The feature set of the Fuji 6MBP100RA060 is precisely tailored for specific industrial applications where reliability and efficiency are paramount.

- Variable Frequency Drives (VFDs): This module is the quintessential building block for small to medium VFDs. Its all-in-one nature simplifies the power stage, allowing designers to focus on control logic and user interface development. The result is a faster time-to-market for general-purpose motor controllers.

- AC Servo Systems: In high-precision motion control, managing regenerative energy is critical. The integrated brake chopper provides a ready-made solution for dynamic braking, dissipating excess energy during deceleration and ensuring tight position control without requiring an external braking unit. This is a crucial element in applications like robotic servo drives.

- Uninterruptible Power Supplies (UPS): The robust converter and inverter stages make the module suitable for the power conversion core of commercial UPS systems, providing a reliable and compact solution for ensuring power continuity.

Key Parameter Overview

The following table highlights the critical electrical characteristics that define the performance of the 6MBP100RA060. For a comprehensive list of parameters, engineers should consult the official product datasheet. Download the Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 600 V |

| Collector Current (Ic) @ Tc=80°C | 100 A |

| Collector-Emitter Saturation Voltage (Vce(sat)), typ. | 2.2 V |

| Forward Voltage Diode (Vf), typ. | 2.0 V |

| Maximum Junction Temperature (Tj max) | 150 °C |

| Internal Configuration | 3-Phase Converter + Brake Chopper + 3-Phase Inverter |

Frequently Asked Questions (FAQ)

What is the primary benefit of using a PIM like the 6MBP100RA060 over discrete components?

While discrete IGBTs and diodes offer design flexibility, a PIM provides superior power density, proven reliability, and a significantly simplified manufacturing process. For applications like motor drives under 15 kW, the PIM approach reduces assembly time, lowers the Bill of Materials (BOM) by integrating bus bars and substrates, and minimizes design risks associated with layout parasitics. This holistic integration is a core principle behind modern IGBT modules.

How does the integrated NTC thermistor improve system reliability?

The built-in Negative Temperature Coefficient (NTC) thermistor provides real-time temperature feedback directly from the module's substrate. This is far more accurate than an external sensor on the heatsink. A motor drive's control board can use this data to trigger alarms, derate the output power, or initiate a safe shutdown if the module approaches its thermal limits. This proactive thermal monitoring is a key defense against overtemperature failures, dramatically extending the operational life of the drive. For specific integration guidance, please contact our technical team.