6MBP150RA060-02: Engineering Analysis of a 600V, 150A Integrated IGBT-PIM

A Highly Integrated Power Module for Efficient and Compact Motor Control

Content last revised on October 15, 2025.

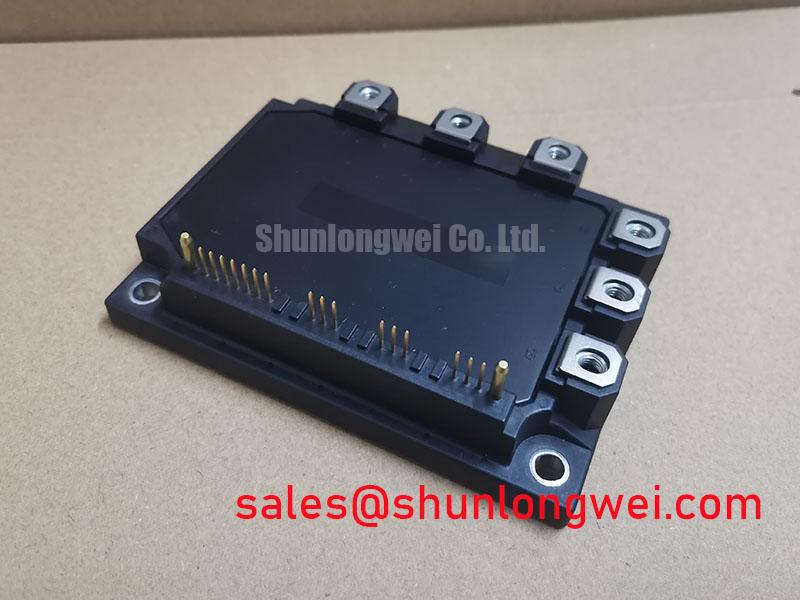

The Fuji Electric 6MBP150RA060-02 is a Power Integrated Module (PIM) engineered to deliver high efficiency and power density for compact motor drive applications. This module consolidates a complete CIB (Converter-Inverter-Brake) topology into a single package, rated for 600V and 150A. Its design prioritizes low conduction losses (VCE(sat) of 1.70V typ.) and features integrated protection circuits, enabling simplified power stage design and enhanced system reliability. Best suited for variable frequency drives up to 75 kW, the 6MBP150RA060-02 provides a robust foundation for systems where space and efficiency are critical design constraints.

Application Scenarios & Value

System-Level Benefits in Compact Industrial Motor Drives

The primary value of the 6MBP150RA060-02 lies in its ability to accelerate the design and shrink the footprint of low- to medium-power motor control systems. Consider an engineer developing a next-generation Variable Frequency Drive (VFD) for a 55 kW AC induction motor operating on a 400V AC line. The key challenge is often maximizing power density while ensuring robust, reliable operation. A discrete solution would require sourcing, qualifying, and assembling separate rectifier diodes, a three-phase inverter bridge, a braking chopper IGBT, and associated driver and protection circuits. This increases component count, PCB complexity, and potential points of failure.

The 6MBP150RA060-02 directly addresses this challenge. By integrating all these power stages into one thermally-optimized module, it drastically reduces the physical size of the power electronics. This integration minimizes stray inductance between stages, a common source of voltage overshoots during high-frequency Pulse Width Modulation (PWM) switching. Furthermore, the built-in over-current, over-temperature, and under-voltage lockout functions remove significant complexity from the external control board design, leading to a faster development cycle and a more reliable end product. For systems requiring a higher current rating, the related 6MBP200RA060 offers a similar integrated topology with a 200A capability.

Key Parameter Overview

Decoding Key Specifications for Efficient Power Conversion

The performance of the 6MBP150RA060-02 is defined by its electrical and thermal characteristics, which are optimized for motor drive applications. The following table highlights the critical parameters derived from the official datasheet.

| Parameter | Value |

|---|---|

| Inverter Part (IGBT & FWD) | |

| Collector-Emitter Voltage (Vces) | 600V |

| Collector Current (Ic) @ Tc=80°C | 150A |

| Collector-Emitter Saturation Voltage (VCE(sat)) @ Ic=150A | 1.70V (Typ.) / 2.15V (Max.) |

| Forward Voltage (Vf) @ Ie=150A | 1.75V (Typ.) / 2.25V (Max.) |

| Thermal Resistance, Junction to Case (Rth(j-c)) - IGBT | 0.24 °C/W (Max.) |

| Converter Part (Diode Bridge) | |

| Repetitive Peak Reverse Voltage (VRRM) | 600V |

| Average Forward Current (Io) | 150A |

| Brake Part (IGBT & FWD) | |

| Collector-Emitter Voltage (Vces) | 600V |

| Collector Current (Ic) @ Tc=80°C | 75A |

| Control & Protection | |

| Control Supply Voltage (Vcc) | 15.0V (Typ.) |

| Integrated Protections | Over-Current (OC), Over-Temperature (OT), Short-Circuit (SC), Under-Voltage (UV) |

Download the 6MBP150RA060-02 datasheet for detailed specifications and performance curves.

Two key parameters dictate the module's efficiency and thermal design requirements. First, the low Collector-Emitter Saturation Voltage (VCE(sat)) of 1.70V at the nominal 150A rating is crucial. Think of VCE(sat) as a measure of electrical friction when the switch is on. A lower value signifies less energy is converted into waste heat, directly improving the VFD's overall efficiency and reducing the load on the cooling system. Second, the Thermal Resistance (Rth(j-c)) of 0.24 °C/W for the inverter IGBT defines how effectively heat can travel from the active silicon die to the module's baseplate. A low thermal resistance is essential for keeping the junction temperature within safe limits under heavy loads, ensuring long-term operational reliability.

Technical Deep Dive

Inside the PIM: A Look at the Integrated CIB Topology and its Impact on Reliability

The 6MBP150RA060-02 is more than just a collection of components; it is a systematically engineered Power Integrated Module. Its CIB (Converter-Inverter-Brake) topology integrates three distinct but interdependent power functions. The converter stage uses a three-phase diode bridge to rectify the incoming AC line voltage into a stable DC bus. The inverter stage, built with six IGBTs and six free-wheeling diodes (FWDs), synthesizes a variable frequency, variable voltage AC output to control motor speed and torque. The brake circuit, a single IGBT with an anti-parallel FWD, provides a path to dissipate regenerative energy from the motor during deceleration, preventing DC bus overvoltage.

The engineering advantage of this integration is twofold. First, it enhances electrical performance. By placing all power semiconductors within a single, compact housing, the parasitic inductance of the interconnects is significantly reduced compared to a solution using discrete components wired on a PCB. This is critical for minimizing voltage spikes and ringing during fast switching, leading to improved electromagnetic compatibility (EMC) and reduced stress on the silicon. Second, it improves thermal management and reliability. The module's structure provides a single, flat baseplate for mounting to a heatsink. This simplifies the mechanical design and ensures a consistent thermal interface for all power devices. The Rth(j-c) can be thought of as a multi-lane "heat highway." A low value, like the 0.24 °C/W here, signifies a wide, unobstructed highway, allowing heat to escape the junction quickly and efficiently. This co-packaging strategy, detailed in resources from manufacturers like Fuji Electric, ensures that components with matched characteristics are used, contributing to more predictable and reliable system behavior over its lifetime.

Frequently Asked Questions (FAQ)

What is the primary benefit of the integrated control circuit in the 6MBP150RA060-02?

The integrated control circuit provides built-in protection for over-current (OC), short-circuit (SC), over-temperature (OT), and control supply under-voltage (UV). This simplifies the external gate driver design, reduces component count on the control board, and enhances the overall robustness of the motor drive system by providing a rapid, localized fault response.

How does the thermal resistance (Rth(j-c)) of 0.24 °C/W impact heatsink selection?

This relatively low thermal resistance value indicates efficient heat transfer from the IGBT junction to the case. For a design engineer, this means that for a given power dissipation, the junction temperature will be lower. This provides more thermal margin, potentially allowing for the use of a smaller, more cost-effective heatsink or enabling operation at higher ambient temperatures without derating, a key consideration for optimizing thermal performance.

Is the 6MBP150RA060-02 suitable for applications with high braking energy?

The integrated brake chopper is rated for a collector current of 75A. This is suitable for managing regenerative energy in a wide range of standard motor deceleration profiles. For applications involving very high inertia loads or frequent, aggressive braking cycles, an external braking unit with higher power handling capacity may be necessary. The suitability depends on a complete analysis of the application's braking energy profile.

What does the CIB topology designation signify?

CIB stands for Converter-Inverter-Brake. It indicates that the module contains all three essential power stages for a standard AC motor drive: a rectifier bridge (Converter), a three-phase inverter bridge (Inverter), and a dynamic braking chopper (Brake). This high level of integration is a core feature of modern Intelligent Power Modules (IPMs) and PIMs.

What is the function of the built-in NTC thermistor?

The integrated NTC (Negative Temperature Coefficient) thermistor provides a real-time temperature feedback signal from inside the module, typically measured at the baseplate. This allows the system's controller to monitor the module's operating temperature accurately, enabling functions like over-temperature warning, shutdown protection, and fan speed control for optimized cooling.

An Engineer's Perspective on System Integration

From a design engineering standpoint, the 6MBP150RA060-02 represents a strategic component choice that shifts focus from low-level circuit design to system-level optimization. By providing a pre-validated, fully integrated power stage, it mitigates common design risks associated with parasitic management, component matching, and thermal stacking in discrete solutions. This allows engineering resources to be allocated to higher-value tasks such as perfecting control algorithms, improving user interface design, and accelerating time-to-market for the final product.