Content last revised on January 22, 2026

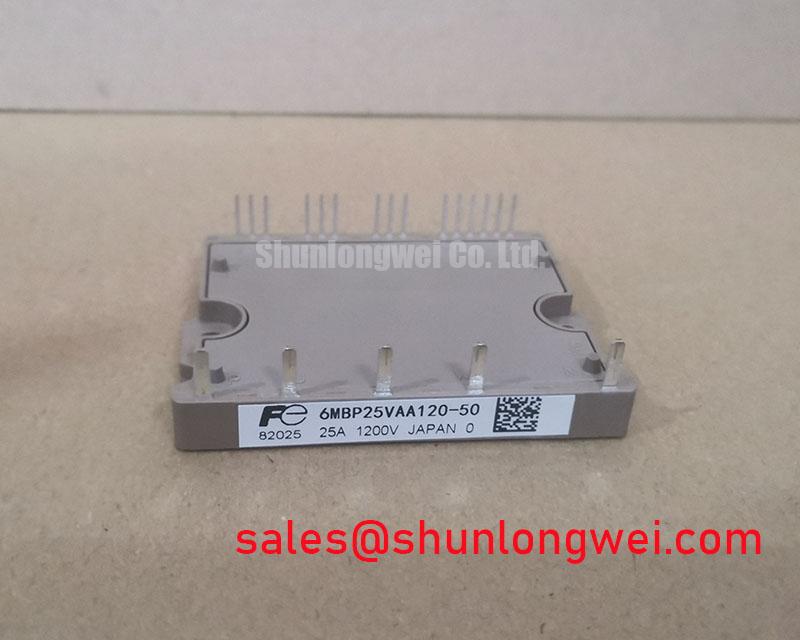

6MBP25VAA120-50: Integrated 1200V CIB IGBT Module

An all-in-one 1200V CIB module that streamlines the design of compact, low-power motor drives by integrating a 3-phase inverter, brake, and converter.

The Fuji Electric 6MBP25VAA120-50 is a highly integrated Power Integrated Module (PIM) designed to accelerate the development of small motor control systems. By consolidating the three primary power stages—rectifier, brake chopper, and inverter—into a single compact package, it directly addresses the engineering challenge of minimizing system footprint and assembly complexity. This integration reduces the need for multiple discrete components, simplifying both the supply chain and the printed circuit board layout for low-power variable frequency drives and servo systems.

Top Specs: 1200V | 25A | 6-in-1 CIB Configuration

Key Benefits:

- Reduced system component count

- Simplified assembly and layout

Intra-Series Comparison & Positioning

Positioning for Peak Integration Efficiency

Within Fuji Electric's V-Series of IGBT modules, the 6MBP25VAA120-50 is strategically positioned for low-power applications where board space, component count, and assembly efficiency are primary design drivers. While higher-power modules in the series focus on minimizing conduction and switching losses for large industrial motors, this 25A model prioritizes integration. Its Converter-Inverter-Brake (CIB) topology offers the most significant value in the sub-4kW motor drive class. In this range, the cost and complexity savings achieved by using a single module often outweigh the benefits of using discrete components, which may be preferred in higher-power systems for more granular thermal management.

Industry Insights & Strategic Advantage

Meeting the Demands of Compact System Design

The ongoing trend toward decentralization and automation in industrial environments places a premium on compact, reliable power electronics. The 6MBP25VAA120-50 directly supports this shift. What is the core benefit of the 6-in-1 CIB topology? It dramatically simplifies design by integrating three power stages into one component. This level of integration is critical in applications like conveyor systems, packaging machinery, and robotics, where the control cabinet size is shrinking, yet functionality is increasing. By providing a pre-engineered, validated power stage, this module allows design teams to focus on control logic and system software, reducing time-to-market for next-generation automated equipment.

Application Scenarios & Value

Streamlining Low-Power Motion Control Systems

The all-in-one architecture of the 6MBP25VAA120-50 delivers tangible value in specific motion control contexts. Its electrical characteristics and physical footprint are engineered for systems where space and simplicity are paramount.

- Small AC Motor Drives: Ideal for general-purpose inverters and Variable Frequency Drives (VFDs) powering pumps, fans, and conveyor belts up to approximately 4 kW. The integrated front-end rectifier and brake circuit eliminate the need for external components, simplifying the power stage design.

- Servo Drives: In robotics and CNC machinery, the module's compact size allows for the development of smaller, more distributed servo amplifiers, enabling more agile and space-efficient machine designs. The integrated nature supports the high-reliability requirements of these automated systems.

- Commercial Appliance Motors: Suitable for motor control in high-performance commercial equipment, such as industrial washing machines or HVAC systems, where a robust and easy-to-implement power solution is required.

For motor drives under 4kW requiring minimal footprint, the 6MBP25VAA120-50's integrated CIB structure is a superior choice over complex discrete solutions.

Key Parameter Overview

Datasheet Specifications for the 6MBP25VAA120-50

The following parameters are based on the official manufacturer's datasheet. For a comprehensive evaluation, engineers should consult the full document. You can Download the Datasheet here.

| Parameter Category | Symbol | Condition | Value |

|---|---|---|---|

| Inverter Part (per IGBT) | |||

| Collector-Emitter Voltage | VCES | - | 1200V |

| Continuous Collector Current | IC | TC = 80°C | 25A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 25A, VGE = 15V, Tj = 125°C | 1.80V (Typ.) / 2.20V (Max.) |

| Brake Part (per IGBT) | |||

| Collector-Emitter Voltage | VCES | - | 1200V |

| Continuous Collector Current | IC | TC = 80°C | 15A |

| Converter Part (per Diode) | |||

| Repetitive Peak Reverse Voltage | VRRM | - | 1600V |

| Average Forward Current | IF(AV) | - | 25A |

| Thermal & Electrical Characteristics | |||

| Thermal Resistance (Inverter IGBT) | Rth(j-c) | Junction to Case | 0.60 °C/W (Max.) |

| Operating Junction Temperature | Tj | - | +150°C |

| Isolation Voltage | Viso | AC 1 minute | 2500V |

Technical Deep Dive

Anatomy of an Integrated Power Stage

A granular analysis of the 6MBP25VAA120-50's specifications reveals how its design choices contribute to simplified system engineering. Understanding these key parameters is essential for leveraging the full potential of this CIB module, as detailed in our guide on decoding IGBT datasheets.

- Collector-Emitter Saturation Voltage (VCE(sat)): The typical VCE(sat) of 1.80V at a junction temperature of 125°C is a critical factor for thermal performance. This parameter acts like a small, unavoidable voltage drop when the switch is on. A lower VCE(sat) directly translates to lower conduction losses, meaning less heat is generated during operation. This allows for more compact heatsink designs or greater thermal margin in challenging operating environments.

- Thermal Resistance (Rth(j-c)): The module specifies a maximum thermal resistance of 0.60 °C/W for an inverter IGBT. This value represents the efficiency of heat transfer from the silicon chip to the module's baseplate. How does this module aid in thermal management? It provides a single, characterized thermal interface for simplified heatsink design. Instead of calculating and managing the thermal paths of over a dozen discrete devices, the designer works with a single, predictable value, greatly simplifying the thermal design process.

- Integrated Thermistor: The inclusion of an NTC thermistor provides a direct and reliable method for monitoring the module's internal temperature. This built-in sensor allows the control system to implement over-temperature protection without the need for external sensors, saving board space and ensuring the thermal feedback loop is tightly coupled to the power devices.

Frequently Asked Questions (FAQ) about the 6MBP25VAA120-50

For detailed technical evaluation or to discuss how the 6MBP25VAA120-50 can be integrated into your specific application, please review the official datasheet and consult with your design engineering team to verify its suitability for your system's requirements.