Content last revised on January 13, 2026

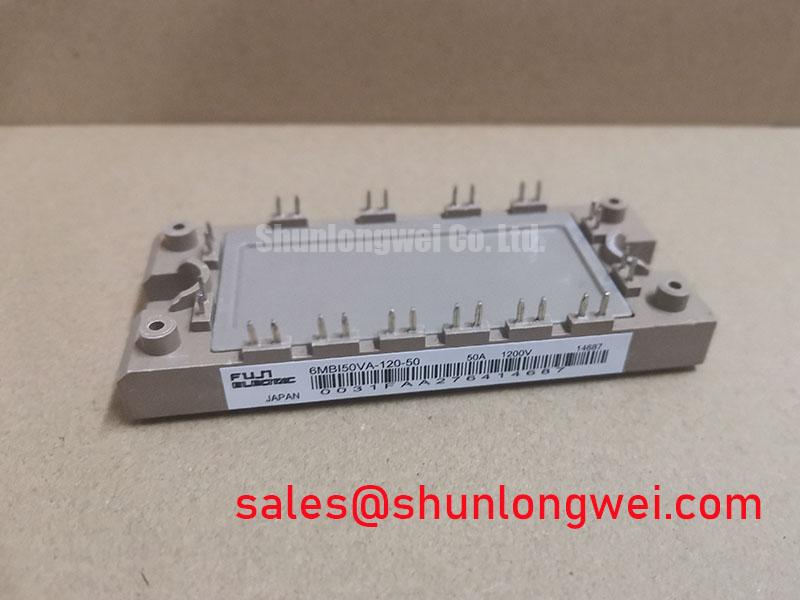

Fuji Electric 6MBI50VA-120-50 | V-Series PIM for High-Efficiency Motor Control

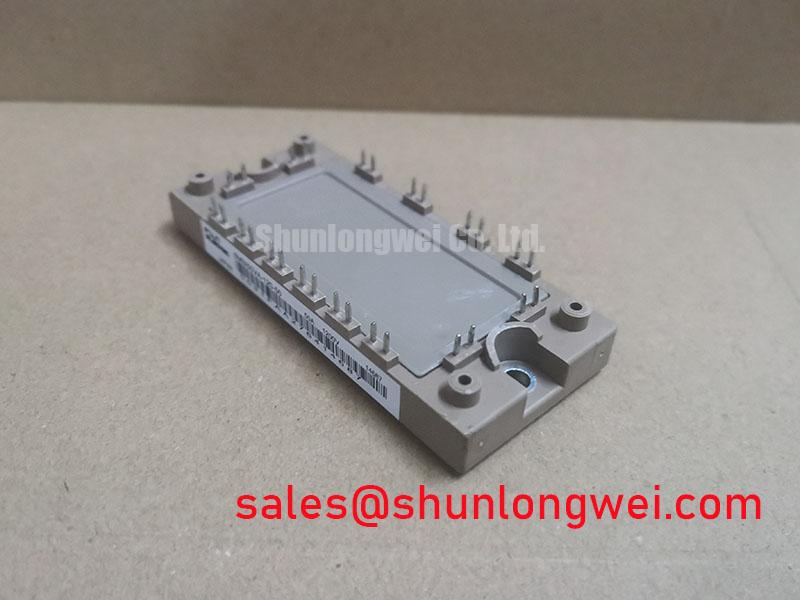

The Fuji Electric 6MBI50VA-120-50 is a highly integrated Power Integrated Module (PIM) engineered to deliver a superior balance of performance, efficiency, and reliability for low-to-medium power applications. By combining a three-phase inverter, brake chopper, and rectifier bridge into a single compact package, this V-Series IGBT module provides a streamlined solution for system designers looking to reduce assembly complexity, minimize board space, and enhance thermal management in demanding industrial environments.

Core Engineering Advantages

This module is built upon Fuji Electric's advanced V-Series technology, offering tangible benefits that translate directly into system-level improvements:

- Optimized Power Density: The all-in-one PIM architecture significantly reduces the component count and PCB footprint compared to discrete solutions, enabling more compact and cost-effective designs for applications like small Variable Frequency Drives (VFDs).

- Superior Conduction Efficiency: Leveraging V-Series Trench Gate and Field-Stop (FS) technology, the 6MBI50VA-120-50 achieves a low saturation voltage (VCE(sat)), minimizing conduction losses and improving overall energy efficiency.

- Enhanced System Reliability: An integrated NTC thermistor provides real-time temperature feedback to the control system, allowing for precise thermal monitoring and protection against overheating conditions, a common cause of IGBT failure.

- Simplified Assembly: The single-module design reduces manufacturing complexity, lowers stray inductance, and simplifies thermal interface management, leading to faster and more reliable production cycles.

Technical Deep Dive: V-Series Technology and PIM Architecture

At the heart of the Fuji Electric 6MBI50VA-120-50 is its sophisticated semiconductor design. The V-Series IGBTs employ a refined Trench Gate structure combined with a Field-Stop layer. This engineering approach optimizes the charge carrier profile within the device, achieving a superior trade-off between on-state voltage drop and switching speed. The direct consequence for designers is a reduction in total power loss—both conduction and switching—which allows for smaller heatsinks and higher operational efficiency, especially under heavy load conditions.

The Power Integrated Module (PIM) topology further enhances its value. By co-packaging the essential power stages (rectifier, inverter, and brake chopper), the module inherently minimizes the parasitic inductance in the high-current DC link path. This is critical for reducing voltage overshoots during high-speed switching events, which simplifies snubber circuit design and improves the overall electromagnetic compatibility (EMC) of the system. This level of integration is a key reason why IGBT modules are foundational to modern power electronics.

Key Parameter Overview

The following table outlines the critical electrical and thermal characteristics. For a comprehensive list of parameters, please refer to the official datasheet.

Download the complete Fuji Electric 6MBI50VA-120-50 Datasheet

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Continuous Collector Current (Ic) @ Tc=80°C | 50 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) (Typ. @ Ic=50A, Tj=125°C) | 1.70 V |

| Total Power Dissipation (Pc) @ Tc=25°C | 310 W (per IGBT) |

| Operating Junction Temperature (Tj(op)) | -40 to +150 °C |

| Package Type | M633 |

Application Scenarios & Value Proposition

The unique feature set of the Fuji Electric 6MBI50VA-120-50 makes it an ideal choice for several key applications:

- AC Motor & Servo Drives: In industrial automation, the module’s integrated brake chopper is invaluable for managing regenerative energy during motor deceleration, ensuring stable and safe operation. Its fast switching characteristics support the high-precision control required in robotic servo drives.

- General Purpose Inverters: The robust and thermally efficient design provides a reliable power core for a wide range of power conversion equipment, from conveyor belt systems to industrial pumps and fans.

- Uninterruptible Power Supplies (UPS): The high reliability, underpinned by the NTC thermistor and low-loss operation, makes it a dependable component for critical power backup systems where efficiency and uptime are paramount.

Frequently Asked Engineering Questions (FAQ)

Q: What is the primary benefit of using this PIM over discrete IGBTs and diodes for a 5-7.5kW drive design?

A: The main benefits are system simplification and improved reliability. The PIM drastically reduces component count, assembly time, and potential points of failure. Furthermore, the thermal characteristics of all semiconductor components are matched and managed on a single substrate, leading to more predictable and efficient heat dissipation compared to a scattered layout of discrete devices.

Q: How should the integrated NTC thermistor be utilized in a gate drive circuit?

A: The NTC thermistor should be connected to an analog input on the system's microcontroller or a dedicated monitoring IC. The control firmware can then use a lookup table or formula from the datasheet to convert the resistance reading into a temperature value. This data should be used to trigger a two-stage protection scheme: a soft de-rating of the output current as temperature approaches the upper limit, followed by a complete shutdown (fault trip) if a critical temperature is exceeded, thus preventing catastrophic module failure.