Content last revised on January 15, 2026

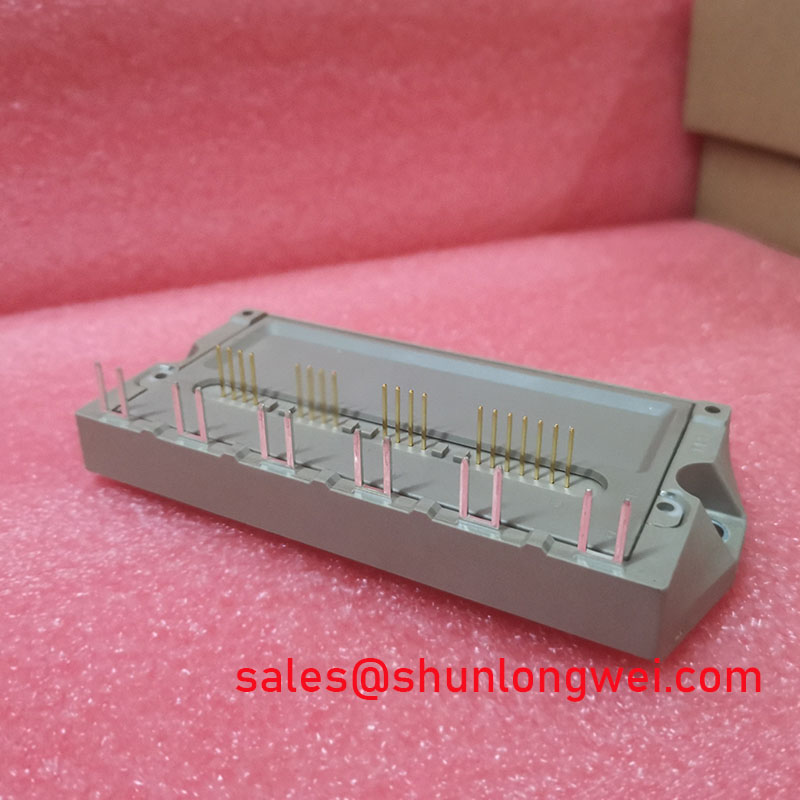

Fuji 7MBP100TEA060-52 | High-Density 600V/100A PIM for Advanced Motor Control

The Fuji Electric 7MBP100TEA060-52 is not just another IGBT module; it's a highly integrated Power Integrated Module (PIM) engineered to solve core design challenges in modern, compact motor drives. By co-packaging a three-phase inverter bridge with a brake chopper circuit, this module delivers a streamlined solution for AC servo systems, general-purpose variable frequency drives (VFDs), and robotics applications where power density, efficiency, and reliability are non-negotiable.

Highlights of the 7MBP100TEA060-52 PIM

- Integrated 7-in-1 Topology: Combines a 600V/100A three-phase inverter bridge with a brake chopper IGBT and freewheeling diode, simplifying PCB layout and reducing system assembly costs.

- Optimized for Motor Drive Efficiency: Features low collector-emitter saturation voltage (VCE(sat)) of 1.7V (typ.) at 100A, directly minimizing conduction losses and improving thermal performance.

- Compact P29 Package: Delivers exceptional power density, enabling designers to create smaller, more space-efficient inverter systems without compromising on output power.

- Built-in NTC Thermistor: Provides real-time temperature feedback for precise thermal management and over-temperature protection, enhancing long-term system reliability.

Technical Deep Dive: Engineering Advantage in Detail

Two core engineering decisions make the 7MBP100TEA060-52 a standout choice. First, the 7-in-1 PIM architecture offers more than just component consolidation. By integrating the brake chopper, Fuji Electric significantly reduces stray inductance between the inverter and braking circuits. This is critical in dynamic motor control applications involving rapid deceleration or regenerative braking, as it minimizes voltage overshoots and improves electromagnetic compatibility (EMC) performance, simplifying the design of snubber circuits.

Second, the module's electrical characteristics are meticulously balanced for the target applications. The low VCE(sat) ensures high efficiency in applications where the motor runs at steady state for extended periods. Simultaneously, the switching characteristics are controlled to manage losses and stress during the PWM operation typical in Variable Frequency Drive (VFD) systems, striking an optimal balance between conduction and switching losses for frequencies up to ~15 kHz.

Application Scenarios & Value Proposition

The design of the Fuji 7MBP100TEA060-52 directly addresses the pain points of specific power conversion applications:

- AC Servo Drives: In high-precision motion control, the fast and soft-recovery freewheeling diodes (FWD) paired with the IGBTs enable clean, rapid switching. This translates to higher control loop bandwidth and more accurate positioning, a key requirement in robotics and CNC machinery. For a deeper look into this application, explore our article on the role of IGBTs in robotic servo drives.

- General Purpose Inverters: The integrated brake chopper is invaluable for managing the regenerative energy from a decelerating motor, preventing DC bus overvoltage faults. This built-in functionality simplifies the overall drive design, reduces the bill of materials (BOM), and enhances system robustness in demanding industrial environments.

- Compact Industrial Machinery: For applications like packaging machines, conveyors, and pump systems, the module's high power density allows for the development of smaller control cabinets, saving valuable factory floor space.

Key Technical Parameters

This table summarizes the critical performance specifications for system designers. For a complete overview, you can Download the Datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (VCES) | 600 V |

| Continuous Collector Current (IC) @ Tc=80°C | 100 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) typ. @ IC=100A | 1.7 V |

| Total Power Dissipation (PC) per IGBT | 390 W |

| Short Circuit Withstand Time (tsc) | ≥ 10 µs |

| Operating Junction Temperature (Tj) | +150 °C |

Frequently Asked Engineer Questions (FAQ)

1. What is the primary benefit of the integrated brake chopper in the 7MBP100TEA060-52?The main benefit is system integration. It eliminates the need for an external brake module, simplifying the power stage layout, reducing parasitic inductance, and lowering assembly costs. This is particularly advantageous in compact VFDs where space and component count are critical design constraints.

2. How should I approach thermal design for this P29 package?Effective thermal design is crucial for reliability. The integrated NTC thermistor provides direct temperature feedback. Your thermal stack-up (thermal interface material and heatsink) should be designed to keep the module's case temperature (Tc) well below its maximum rating under worst-case load conditions. Pay close attention to the thermal resistance values in the datasheet, as detailed in our guide to decoding IGBT datasheets, to calculate the required heatsink performance.

For detailed application support or to discuss sourcing for your next project, please contact our technical team.