Content last revised on November 18, 2025

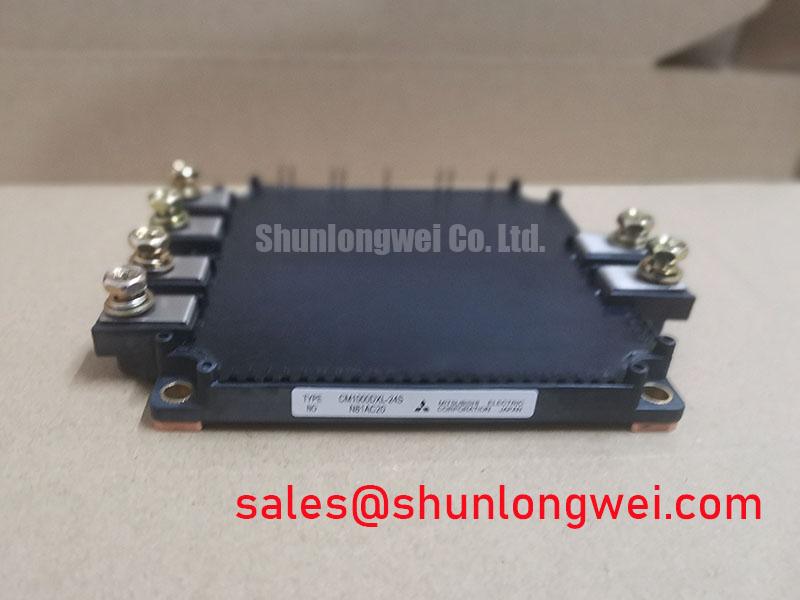

CM1000DXL-24S Mitsubishi IGBT Module: Technical and Application Review

A High-Current 1200V Dual IGBT for Demanding Power Conversion Systems

The Mitsubishi CM1000DXL-24S is a high-power dual IGBT module engineered for superior efficiency and reliability in large-scale power conversion. It integrates seventh-generation CSTBT™ technology to deliver exceptional performance under demanding load conditions. With key specifications of 1200V | 1000A | VCE(sat) 1.70V (typ), this module provides a robust solution for minimizing conduction losses and maximizing thermal stability. Its design directly addresses the challenge of achieving high power density in applications like multi-megawatt wind turbine converters and industrial motor drives. For systems demanding high efficiency and robust thermal performance in the 1000A range, the CM1000DXL-24S offers an optimal balance of low loss and proven reliability.

Application Scenarios & Value

Driving Efficiency in Megawatt-Scale Renewable Energy and Industrial Drives

The CM1000DXL-24S is engineered for high-stress, high-current applications where both efficiency and long-term reliability are paramount. Its primary value is demonstrated in systems such as multi-megawatt central solar inverters, wind turbine pitch and yaw controls, and high-power industrial Variable Frequency Drives (VFDs). In these environments, engineers face the critical challenge of minimizing power loss across thousands of operating hours to maximize energy yield and reduce operating costs. The module's low typical VCE(sat) of 1.70V at its nominal current is a decisive factor, directly translating to lower conduction losses during operation. This is analogous to reducing friction in a mechanical system; less energy is wasted as heat, allowing for more efficient power transfer and potentially smaller, more cost-effective heatsink designs.

This module's robust construction makes it a cornerstone for power stacks in uninterruptible power supplies (UPS) for data centers and large-scale energy storage systems (ESS). Its high current handling capability ensures stable operation during peak load and fault conditions. For applications requiring even greater current capacity, designers might consider the CM1400DU-24NF which offers a higher current rating within a similar voltage class.

Key Parameter Overview

Highlighted Specifications for System Design

The following parameters for the CM1000DXL-24S are critical for performance modeling, thermal management, and ensuring operational reliability. The values are based on the official manufacturer datasheet.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | VGE = 0V | 1200V |

| Collector Current (DC) | IC | TC = 100°C | 1000A |

| Collector Current (Peak) | ICP | 1ms pulse | 2000A |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 1000A, VGE = 15V, Tj = 25°C | 1.70V (Typ.), 2.20V (Max.) |

| Power Dissipation | PC | Per element, TC = 25°C | 5200W |

| Thermal Resistance (Junction-to-Case) | Rth(j-c) | IGBT Part | 0.024 K/W |

| Operating Junction Temperature | Tj | -40 to +150°C | |

| Isolation Voltage | Viso | Main terminal to baseplate, AC 1 min. | 4000Vrms |

Download the CM1000DXL-24S datasheet for detailed specifications and performance curves.

Technical Deep Dive

Implications of 7th Generation CSTBT™ Technology

The core of the CM1000DXL-24S is its utilization of Mitsubishi's 7th generation Carrier Stored Trench-gate Bipolar Transistor (CSTBT™) technology. This advanced chip structure is pivotal in achieving the module's low VCE(sat) characteristic. By optimizing the carrier profile within the silicon, this technology effectively reduces the on-state voltage drop, which is the primary source of conduction losses in an IGBT. This innovation is akin to engineering a wider, smoother highway for electrons to travel; with less "traffic congestion," less energy is converted into waste heat. This efficiency gain is not just a marginal improvement; it enables designers to push for higher power densities or enhance system reliability by operating at lower junction temperatures, a key factor analyzed in resources like the guide to IGBT thermal performance.

Frequently Asked Questions (FAQ)

How does the low VCE(sat) of the CM1000DXL-24S benefit high-power inverter design?

A lower VCE(sat) directly reduces conduction power loss (P_cond = VCE(sat) * IC). In a megawatt-scale inverter, this reduction translates into significant energy savings over the system's lifetime, lower operating temperatures, and allows for a more compact and cost-effective thermal management system, improving overall power density and reliability.

What is the significance of the 4000Vrms isolation voltage?

The 4000Vrms isolation provides a high degree of safety and reliability by ensuring robust electrical separation between the high-voltage power circuit and the grounded baseplate. This is critical for meeting stringent safety standards in industrial and utility-scale equipment, preventing catastrophic failures and ensuring operator safety.

What design considerations are important when using this 1000A module?

Proper gate drive design is crucial to ensure clean and fast switching, minimizing switching losses. Additionally, a low-inductance busbar layout is essential to mitigate voltage overshoots during high-speed switching events. Finally, ensuring a low thermal resistance path from the module's baseplate to the heatsink is vital to effectively dissipate the generated heat and keep the junction temperature within safe limits.

Strategic Advantage

Integrating the CM1000DXL-24S into a power system design is a strategic decision for applications where high-current performance and operational efficiency are non-negotiable. Its foundation on a mature yet advanced chip technology provides a reliable, high-performance building block for next-generation power converters aimed at supporting the global transition to renewable energy and more efficient industrial automation.