Content last revised on October 23, 2025.

Epson EG7009N-NS: A Technical Guide to the Component-Level LCD Panel for Legacy and Custom Designs

M2. Introduction & Core Features

Engineering Snapshot: Component-Level Integration

The Epson EG7009N-NS is a passive STN LCD glass panel offering engineers maximum flexibility for designing custom display assemblies or executing precise repairs on legacy industrial equipment. This component is defined by its fundamental nature: Manufacturer: Epson | Type: Passive LCD Glass | Technology: STN (Super-twisted Nematic). Its primary engineering benefits include complete design freedom and the ability to service long-life systems. This component allows engineers to replace only the failed glass in a custom display assembly, preserving the original driver electronics and housing. Best suited for engineers needing to repair legacy HMI systems or develop highly customized monochrome displays from the component level.

B2. Application Scenarios & Value

System-Level Benefits in Legacy Equipment Repair

The primary value of the EG7009N-NS lies in its role as a fundamental building block for custom display solutions and, critically, for the maintenance of legacy systems. Consider an industrial process controller or a piece of specialized test and measurement equipment designed in the 1990s. These machines are often built for decades of service, but their monochrome displays can be a point of failure due to environmental stress or age. The original display assembly might have been a fully custom unit, making a complete modern replacement impossible without a costly system redesign and recertification.

This is the precise scenario where the EG7009N-NS provides a decisive advantage. As a passive LCD glass panel, it allows a skilled technician to perform a component-level repair. What is the primary benefit of its passive glass design? Enhanced serviceability for custom hardware. By desoldering or releasing the failed glass from the original custom driver board and replacing it with the EG7009N-NS, the integrity and function of the original equipment are restored. This avoids a complete system overhaul, minimizing downtime and extending the life of valuable capital equipment. It empowers engineers to maintain operational continuity for critical infrastructure that relies on older, yet perfectly functional, technology.

B3. Key Parameter Overview

Highlighting the Core Component Characteristics

The EG7009N-NS is a fundamental display component, not a complete plug-and-play module. Its specifications reflect this role, emphasizing its identity and physical nature over integrated electronic performance. The following parameters are derived from publicly available customs rulings and component listings for identification and verification purposes.

| Attribute | Specification | Engineering Significance |

|---|---|---|

| Manufacturer | Epson | Indicates a component built to the high-quality manufacturing standards of a leading brand from the era, crucial for reliability in long-term applications. |

| Part Type | Passive LCD Glass Panel / Display Subassembly | This is the most critical parameter. It confirms the part is a bare LCD glass with connections, requiring an external, custom driver board for operation. | Implied Technology | Monochrome STN (Super-twisted Nematic) | Delivers higher contrast and wider viewing angles compared to older TN technology, essential for readability in industrial HMI and instrumentation. |

| Intended Use | Automated Data Processing (ADP) Equipment | Designed for data-centric displays, typical of terminals, controllers, and scientific instruments where clarity and reliability are paramount. |

Download the EG7009N-NS datasheet for detailed specifications and performance curves. Note: As a legacy component, a complete official datasheet may no longer be in circulation. The provided information is for engineering evaluation.

B1. Technical Deep Dive

A Closer Look: The "Passive Glass Sandwich" Architecture

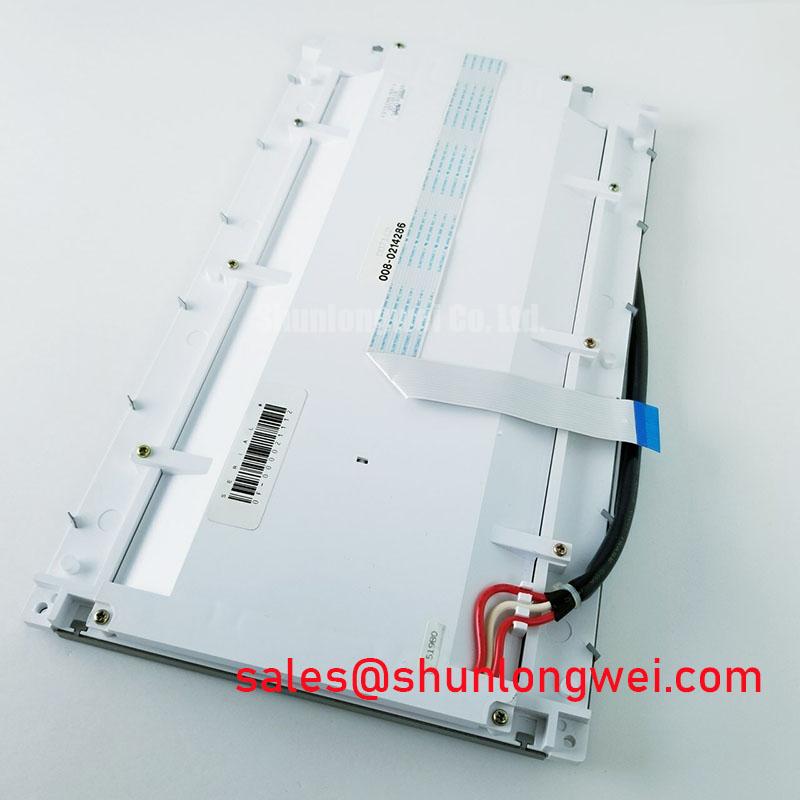

Understanding what the Epson EG7009N-NS is requires differentiating it from modern, integrated display modules. This component is best described as a "passive LCD glass sandwich." It consists of precisely aligned layers: two plates of glass, a sealed-in liquid crystal solution, and polarizing films. On the edges of the glass are conductive traces that terminate in contact pads, which are the sole electrical interface to the component.

What does it include? Only the core optical elements. What does it lack? The brain. There are no integrated driver ICs, no control logic, and no printed circuit board (PCB). To make this panel display an image, an engineer must design a custom driver board that generates the specific voltage waveforms needed to activate the rows and columns of pixels. This signal is typically transferred to the glass through an elastomeric "zebra" connector or a heat-seal connection. Thinking of it in automotive terms, the EG7009N-NS is analogous to a bare engine block. It's the core of the machine, but it requires a custom-built system of pistons, electronics, and fuel delivery (the driver board) to function. This architecture, while demanding more upfront design effort, gives the engineer absolute control over the display's form factor and electronic behavior.

B7. Frequently Asked Questions

Engineering Clarifications for the EG7009N-NS

What is the Epson EG7009N-NS?

The EG7009N-NS is a passive monochrome STN LCD glass panel. It is a fundamental electronic component, not a finished, ready-to-use display module.

Does this display come with a driver board or controller?

No, it does not. It is a "glass-only" component. Users must provide their own external driver circuitry to generate the necessary signals to create an image, making it suitable for fully custom designs or specific legacy repairs.

What is the most common application for a component like this today?

Its primary application is the repair and maintenance of aging industrial, medical, or test equipment that was originally designed with this specific LCD glass. It allows for a targeted replacement of just the failed display panel.

Why would an engineer choose a passive glass panel over an integrated module?

An engineer would choose this for two main reasons: 1) To perform a precise repair on a legacy system where only the glass has failed. 2) For new product development where a highly customized shape, size, or driver electronic solution is required that off-the-shelf modules cannot provide.

What kind of connection does this panel typically use?

While a datasheet is unavailable, passive glass panels of this vintage commonly use either elastomeric connectors (often called "zebra strips") for pressure-based contact with a PCB or a flexible ribbon for heat-seal bonding. Verification of the original design is essential.

Enabling Your Engineering Decisions

For engineering teams tasked with supporting mission-critical legacy systems or developing highly specialized equipment, having access to component-level parts like the Epson EG7009N-NS is a strategic advantage. Understanding its fundamental nature as a passive glass panel is the first step toward a successful repair or integration. For assistance in verifying this component against your system's requirements, our team is available to help cross-reference available documentation to support your decision-making process.