Content last revised on January 10, 2026

Infineon FP25R12KT3 | Highly Integrated CIB Module for Compact Drives

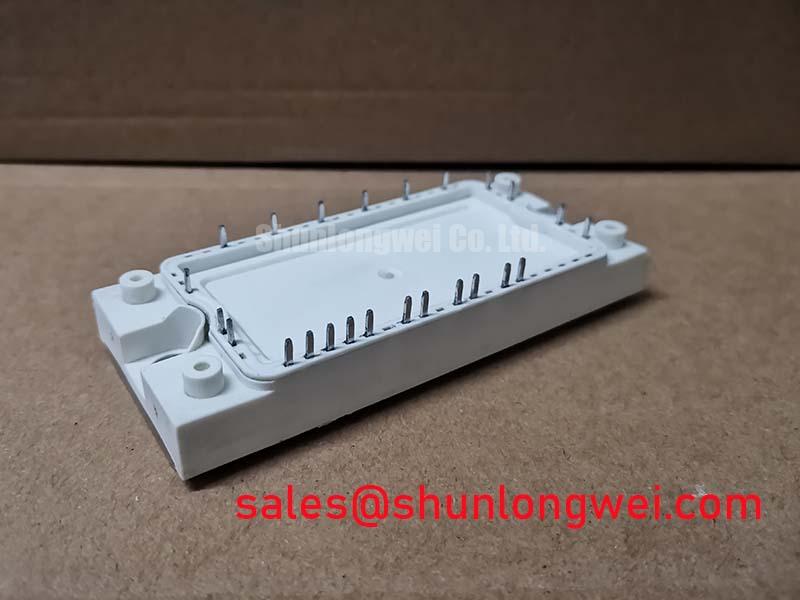

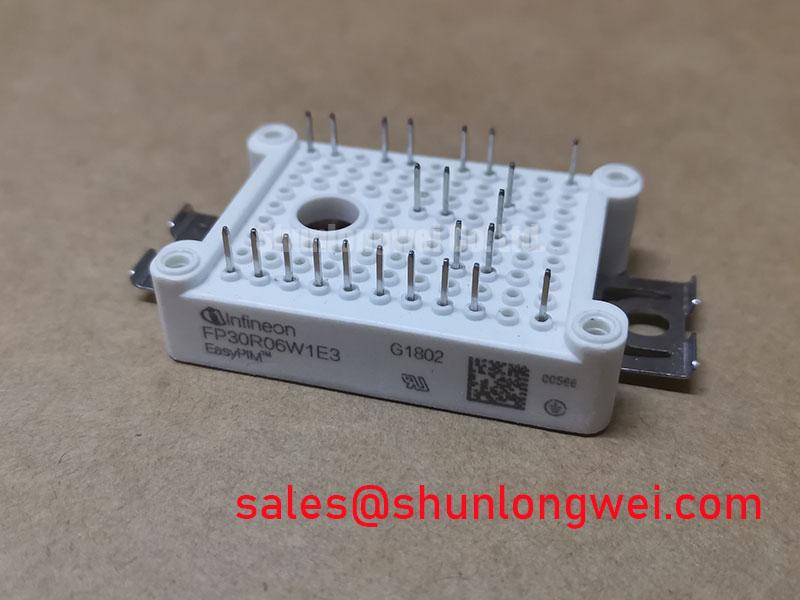

The Infineon FP25R12KT3 is not just an IGBT module; it's a complete power conversion stage engineered for performance and integration. As a Converter-Inverter-Brake (CIB) module, this 1200V, 25A device combines a three-phase input rectifier, a brake chopper, and a three-phase inverter bridge into a single, robust EconoPIM™ 2 package. The Infineon FP25R12KT3 is an ideal solution for designers of compact motor drives, servo systems, and industrial automation equipment who need to reduce system complexity, shrink footprint, and accelerate time-to-market without compromising on reliability.

Technical Deep Dive: The Core of Efficiency and Integration

-

TrenchSTOP™ IGBT3 Technology

At the heart of the FP25R12KT3 lies Infineon's proven TrenchSTOP™ IGBT3 technology. This design achieves a very low collector-emitter saturation voltage (Vce(sat)), which directly translates to lower conduction loss. For your application, this means less waste heat generated during operation, allowing for smaller heatsinks, reduced cooling requirements, and ultimately, lower system-level costs and higher power density.

-

All-in-One CIB Topology

The integrated Converter-Inverter-Brake (CIB) configuration is a game-changer for compact designs. By consolidating three critical power stages, it drastically cuts down on external component count, simplifies PCB layout, and reduces assembly complexity. The module also includes a fast and soft-switching anti-parallel diode, which minimizes electromagnetic interference (EMI), simplifying the design and cost of your system's filtering stage.

Application Scenarios: Where the FP25R12KT3 Delivers Tangible Value

- Compact Motor Drives: In applications like conveyor belts, pumps, and fans, board space is a premium. The FP25R12KT3's high level of integration frees up valuable PCB real estate and reduces manufacturing costs by minimizing solder joints and assembly steps.

- Servo Control Systems: Precision and dynamic response are key in servo applications. The module's efficient thermal performance and robust IGBTs ensure stable operation during rapid acceleration and deceleration cycles, while the integrated brake chopper effectively manages regenerative energy.

- Uninterruptible Power Supplies (UPS): Reliability is non-negotiable in UPS systems. The reduced component count of a CIB module inherently increases system reliability. The low Vce(sat) of the Infineon FP25R12KT3 contributes to higher overall efficiency, extending battery runtime during power outages.

- Industrial Automation Machinery: For multi-axis machinery or distributed control systems, this module provides a standardized, easy-to-implement power block, streamlining design across different machine sizes and functionalities.

Key Technical Specifications

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 1200 V |

| Continuous Collector Current (Ic @ Tc=80°C) | 25 A |

| Topology | Converter-Inverter-Brake (CIB) / PIM |

| Vce(sat) (Typ @ Ic=25A, Tvj=25°C) | 1.70 V |

| Package | EconoPIM™ 2 |

| Integrated NTC Thermistor | Yes |

For a complete list of parameters, please refer to the official FP25R12KT3 Datasheet.

Selection Guidance & Competitive Context

When selecting a power module, it's crucial to balance performance with cost. The Infineon FP25R12KT3 represents a highly optimized choice for applications operating with switching frequencies typically up to 8 kHz. While newer IGBT generations might offer slightly lower switching losses for high-frequency designs, the IGBT3 technology within this module provides an exceptional balance of low conduction losses and robustness, making it a more cost-effective solution for a wide range of mainstream industrial applications. Compared to a fully discrete solution, the FP25R12KT3 offers undeniable advantages in assembly speed, reliability, and design simplicity.

If your design requires operation at higher frequencies or demands extreme power density, you may want to Explore More IGBT Modules featuring the latest chip technologies. For most standard drive applications, however, the FP25R12KT3 remains a benchmark for integrated performance.

Frequently Asked Questions (FAQ)

- What is the primary advantage of the integrated NTC thermistor?The built-in NTC thermistor provides a direct, real-time temperature reading of the module's baseplate. This allows the system controller to implement precise over-temperature protection, preventing thermal runaway and significantly enhancing long-term system reliability.

- How does the brake chopper in the FP25R12KT3 work?The brake chopper consists of an IGBT and a freewheeling diode. When a motor decelerates, it acts as a generator, sending excess energy back to the DC link and raising its voltage. The controller can switch the brake IGBT to divert this energy through an external braking resistor, dissipating it as heat and protecting the DC link capacitors from overvoltage damage.

If the Infineon FP25R12KT3 aligns with your project requirements, or if you need assistance in selecting the right power module, please do not hesitate to Contact Us for a Quote and expert consultation.