Content last revised on November 21, 2025

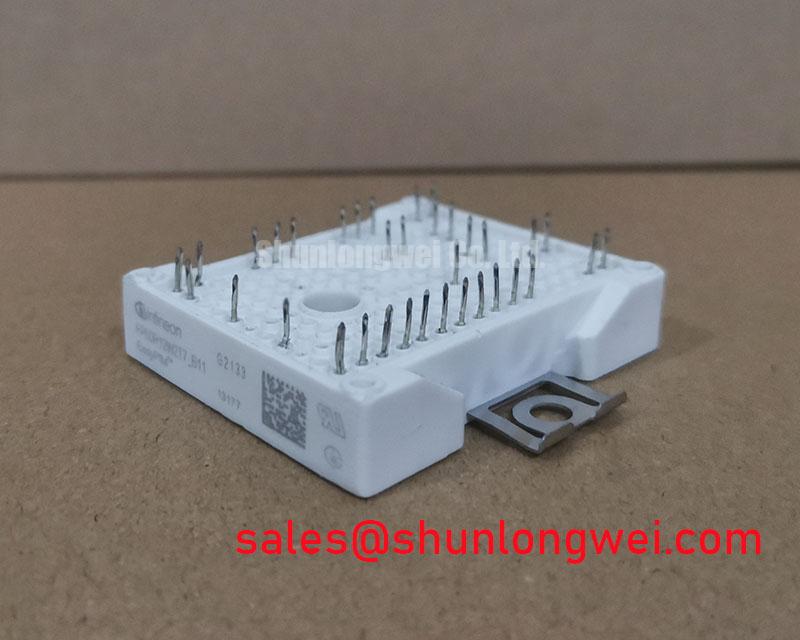

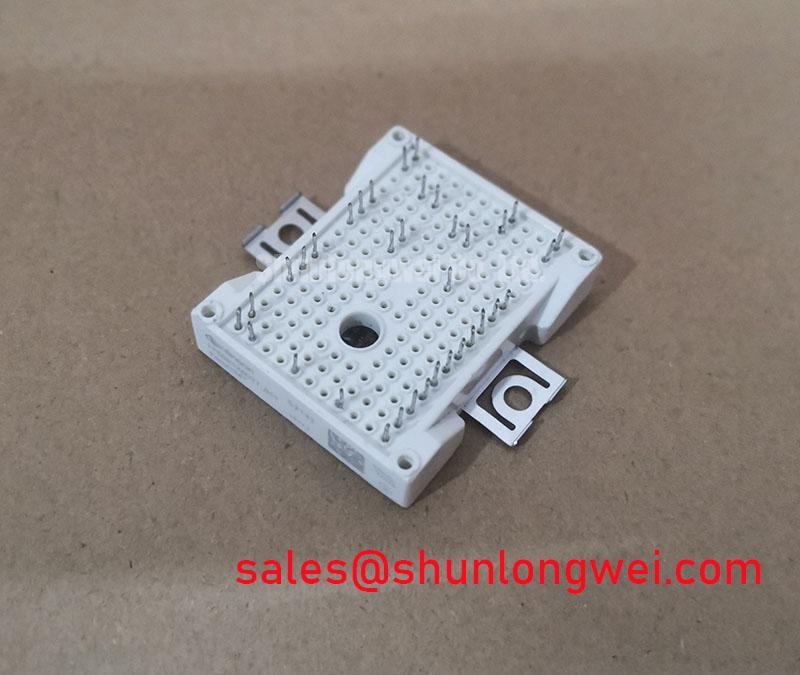

FP50R12W2T7_B11: High-Efficiency 1200V, 50A Three-Level IGBT Module

An Engineering Perspective on System Optimization

The Infineon FP50R12W2T7_B11 is a 1200V, 50A power integrated module (PIM) that leverages an advanced three-level Neutral Point Clamped (NPC) topology and TRENCHSTOP™ IGBT7 technology. This design delivers superior efficiency and thermal performance in a compact EasyPIM™ 2B package. Key benefits include significantly reduced switching losses and solder-free manufacturing reliability via PressFIT contact technology. The module directly addresses the engineering challenge of maximizing power conversion efficiency in high-frequency applications. For systems where minimizing switching losses is paramount, the three-level topology of the FP50R12W2T7_B11 makes it a superior choice over conventional two-level designs.

Application Scenarios & Value

Maximizing Energy Harvest in Solar and UPS Systems

In applications like Solar Inverter systems and Uninterruptible Power Supplies (UPS), every fraction of a percent in efficiency translates directly to tangible value—either as more harvested energy or extended battery runtime. The FP50R12W2T7_B11 is engineered specifically for this challenge. Its three-level NPC topology fundamentally reduces the voltage stress across the switching devices, enabling lower switching losses compared to traditional two-level inverters. This is analogous to a transmission shifting to a higher gear; it allows the system to operate at higher frequencies with less energy wasted as heat. This core benefit is critical for the DC-AC conversion stage in grid-tied inverters, where maximizing power throughput is a primary design goal. The integrated NTC thermistor provides precise, real-time temperature data, allowing for optimized thermal management and enhanced system protection. For applications requiring a standard three-phase, two-level inverter configuration at a similar current rating, designers might consider the FP50R12KT4.

Key Parameter Overview

Critical Specifications for High-Frequency Designs

The performance of the FP50R12W2T7_B11 is defined by a set of parameters optimized for efficiency and reliability. The table below highlights the specifications most critical for design engineers working on high-frequency power conversion systems.

| Parameter | Symbol | Value | Condition |

|---|---|---|---|

| Collector-Emitter Voltage | VCES | 1200 V | Tvj = 25°C |

| Nominal Collector Current | IC nom | 50 A | TC = 100°C |

| Collector-Emitter Saturation Voltage (Typ.) | VCEsat | 1.70 V | IC = 50 A, VGE = 15 V, Tvj = 25°C |

| Total Switching Energy (Typ.) | Etot | 4.20 mJ | IC = 50 A, VCE = 600 V, VGE = ±15 V, RG = 10 Ω, Tvj = 150°C |

| Thermal Resistance, Junction-to-Case (per IGBT) | RthJC | 0.38 K/W | - |

| Operating Junction Temperature | Tvj op | -40 to +175 °C | Overload operation |

Download the FP50R12W2T7_B11 datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Manufacturing and Reliability Benefits of PressFIT Technology

Beyond its electrical performance, the FP50R12W2T7_B11 incorporates PressFIT contact technology, a critical feature for enhancing manufacturing efficiency and long-term reliability. Unlike traditional solder-pin designs, PressFIT pins create a robust, gas-tight cold-welded connection when pressed into a plated-through hole on the PCB. This solder-free process eliminates a thermal cycle during assembly, reducing manufacturing time and cost. What is the primary benefit of its PressFIT design? Enhanced long-term reliability by eliminating solder fatigue. Solder joints are a common point of failure in power electronics, especially in applications with significant temperature cycling, such as solar inverters exposed to daily sun-shade cycles. By removing solder, the PressFIT connection offers superior resilience against thermal and mechanical stress, directly contributing to a longer operational lifetime for the end system. This is akin to using a precision-machined, bolted connection in a mechanical assembly instead of a welded one—it's stronger, more consistent, and more resistant to fatigue over time.

Frequently Asked Questions (FAQ)

What is the main advantage of the three-level NPC topology in the FP50R12W2T7_B11?

The primary advantage is a significant reduction in switching losses. Because the IGBTs only switch half of the DC-link voltage, the energy lost during each on/off transition is substantially lower, enabling higher switching frequencies and improving overall system efficiency, which is crucial for applications like DC fast chargers and solar inverters.

How does the PressFIT mounting technology improve the reliability of a power system?

PressFIT technology creates a solder-free, cold-welded connection between the module and the PCB. This eliminates solder joints, which are common failure points due to thermal cycling fatigue. The result is a more mechanically robust and reliable connection, extending the operational life of the entire power converter.

Can the FP50R12W2T7_B11 be used in motor drive applications?

While optimized for solar and UPS systems, its robust design and TRENCHSTOP™ IGBT7 technology make it suitable for auxiliary inverters and some motor drive applications where high efficiency is a key requirement.

What is the function of the integrated NTC thermistor?

The integrated NTC thermistor provides a means for real-time temperature monitoring of the module's substrate. This feedback is essential for the system's control loop to implement effective thermal management and over-temperature protection, ensuring the module operates within its safe operating area and preventing catastrophic failure.

From a strategic design perspective, the FP50R12W2T7_B11 represents a move towards specialized components that solve system-level problems. By integrating a high-efficiency topology with a highly reliable mounting technology, it enables engineers to not only meet but exceed modern energy efficiency standards like those for grid-tied inverters, while simultaneously simplifying the manufacturing process and improving the long-term field reliability of their products.