Content last revised on November 16, 2025

Infineon FS75R12KE3 | The Engineer's Choice for Robust 1200V/75A Motor Drives

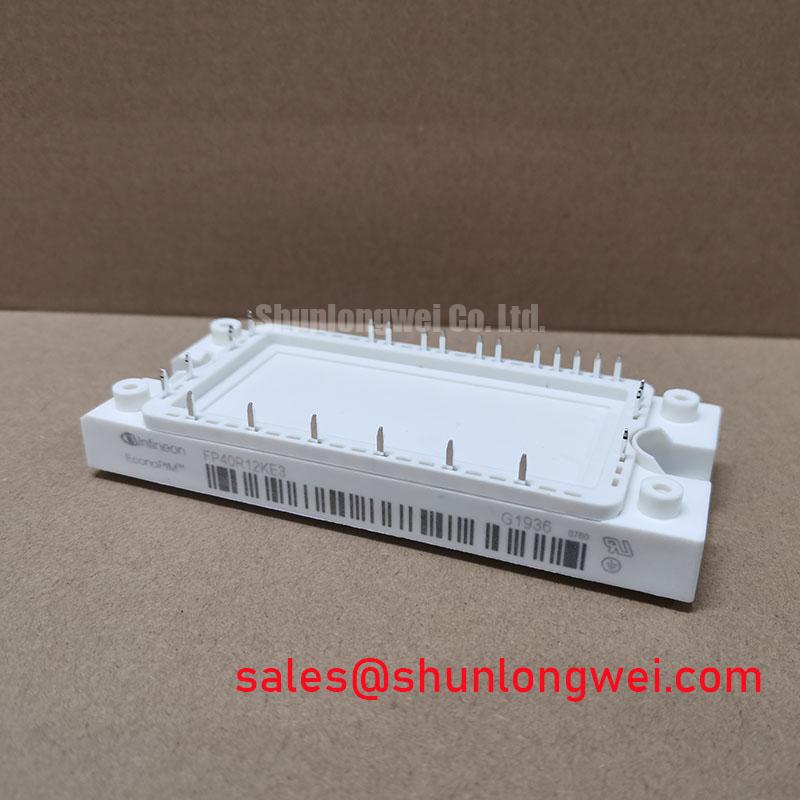

The Infineon FS75R12KE3 is not just another component; it's a foundational building block for reliable and efficient power conversion systems. Engineered for the demanding environment of industrial applications, this 1200V/75A Sixpack IGBT module from Infineon delivers a masterful balance of performance, thermal stability, and long-term durability. It represents a proven solution for engineers developing systems where uptime and energy efficiency are non-negotiable.

- Optimized for Low Conduction Losses: Built on Infineon's mature TRENCHSTOP™ IGBT3 technology, it significantly reduces VCE(sat), leading to lower heat dissipation and higher overall system efficiency.

- Industry-Standard EconoPACK™ 3 Package: Simplifies design-in and manufacturing processes with its robust screw terminals and a well-established mechanical footprint, ensuring high reliability and ease of assembly.

- Integrated Sixpack Configuration: Features a full three-phase inverter bridge (six IGBTs with six freewheeling diodes) in a single module, reducing component count, simplifying PCB layout, and minimizing stray inductance.

- Built-in Thermal Sensing: Includes an integrated NTC thermistor, providing a direct and accurate method for monitoring module temperature, which is crucial for implementing effective thermal protection strategies.

Technical Depth Profiling

The performance of the FS75R12KE3 is rooted in two key design choices by Infineon: the silicon technology and the module packaging. Understanding these reveals why this module remains a top choice for cost-effective, high-performance designs.

At its core is the TRENCHSTOP™ IGBT3 technology. This isn't just a marketing term; it describes a specific silicon structure. The "trench gate" allows for a higher channel density, which dramatically lowers the on-state voltage drop, or VCE(sat). For a design engineer, this translates directly into reduced power loss during conduction, meaning less heat to manage and more power delivered to the load. The accompanying "field-stop" layer optimizes the trade-off between VCE(sat) and switching losses, making the FS75R12KE3 exceptionally well-suited for applications operating in the typical motor control frequency range of 2-16 kHz.

Equally important is the EconoPACK™ 3 package. This industry-standard housing is engineered for mechanical robustness. The screw terminals provide a secure and reliable electrical connection, resistant to vibration and thermal cycling, which is a common point of failure in less robust packages. The layout is optimized for low internal inductance, and the integrated NTC thermistor provides the critical feedback needed for a sophisticated thermal management system, preventing catastrophic failures due to overheating.

Application Scenarios & Value Embodiment

The features of the Infineon FS75R12KE3 translate into tangible benefits across several key industrial applications:

- Variable Frequency Drives (VFDs): The module's Sixpack topology is a perfect match for the 3-phase inverter stage of a VFD. Its low conduction losses ensure high efficiency even at high torque and low speeds, while its thermal stability guarantees reliable operation in demanding industrial environments.

- Servo Drives: In applications requiring high precision, such as robotic servo drives, the FS75R12KE3 provides the robust and repeatable performance necessary for accurate position and speed control. The low thermal resistance of the module ensures that heat is efficiently extracted, maintaining system stability during rapid acceleration and deceleration cycles.

- Uninterruptible Power Supplies (UPS): Reliability is paramount in UPS systems. The proven track record of the EconoPACK™ 3 package and the inherent ruggedness of the IGBT3 technology provide the high level of dependability required to protect critical loads.

Key Parameter Overview

For engineers requiring a quick technical reference, the following table summarizes the critical performance characteristics of the FS75R12KE3. For a comprehensive list of specifications, please refer to the official datasheet.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (V_CES) | 1200 V |

| Continuous Collector Current (I_C) @ T_C = 80°C | 75 A |

| Collector-Emitter Saturation Voltage (V_CEsat) @ 75A, 25°C | 1.70 V (Typical) |

| Total Switching Energy (E_ts) @ 75A, 125°C | 9.50 mJ (Typical) |

| Operating Junction Temperature (T_vjop) | -40°C to +150°C |

| Thermal Resistance, Junction-to-Case (R_thJC) per IGBT | 0.19 K/W |

For detailed graphs and operating conditions, Download the Infineon FS75R12KE3 Datasheet.

Frequently Asked Questions (FAQ)

How does the FS75R12KE3's IGBT3 technology compare to newer generations like IGBT7?

This is an excellent engineering question. While newer generations like IGBT7 are optimized for even lower switching losses at higher frequencies, the IGBT3 technology in the FS75R12KE3 offers a superb balance of low conduction losses and robust short-circuit withstand capability. For mainstream motor drives operating below 16 kHz, the IGBT3 often provides a more cost-effective solution with proven field reliability, making it the ideal choice for applications where ultimate switching speed is not the primary design driver.

What are the key considerations for the gate drive design for this module?

A robust gate drive is critical to unlocking the full potential of the FS75R12KE3. Key considerations include:

1. Providing a stable gate voltage, typically +15V for turn-on and a negative voltage (e.g., -8V to -15V) for a secure turn-off, which prevents parasitic turn-on.

2. Utilizing the Kelvin Emitter connection for the driver return path to bypass stray inductance from the main load current path, ensuring cleaner and faster switching.

3. Ensuring the gate driver has sufficient peak current capability to charge and discharge the IGBT's input capacitance effectively. For more in-depth information, review these 5 practical tips for robust IGBT gate drive design.

For detailed selection advice or to discuss your specific application needs, please contact our technical team for expert consultation.