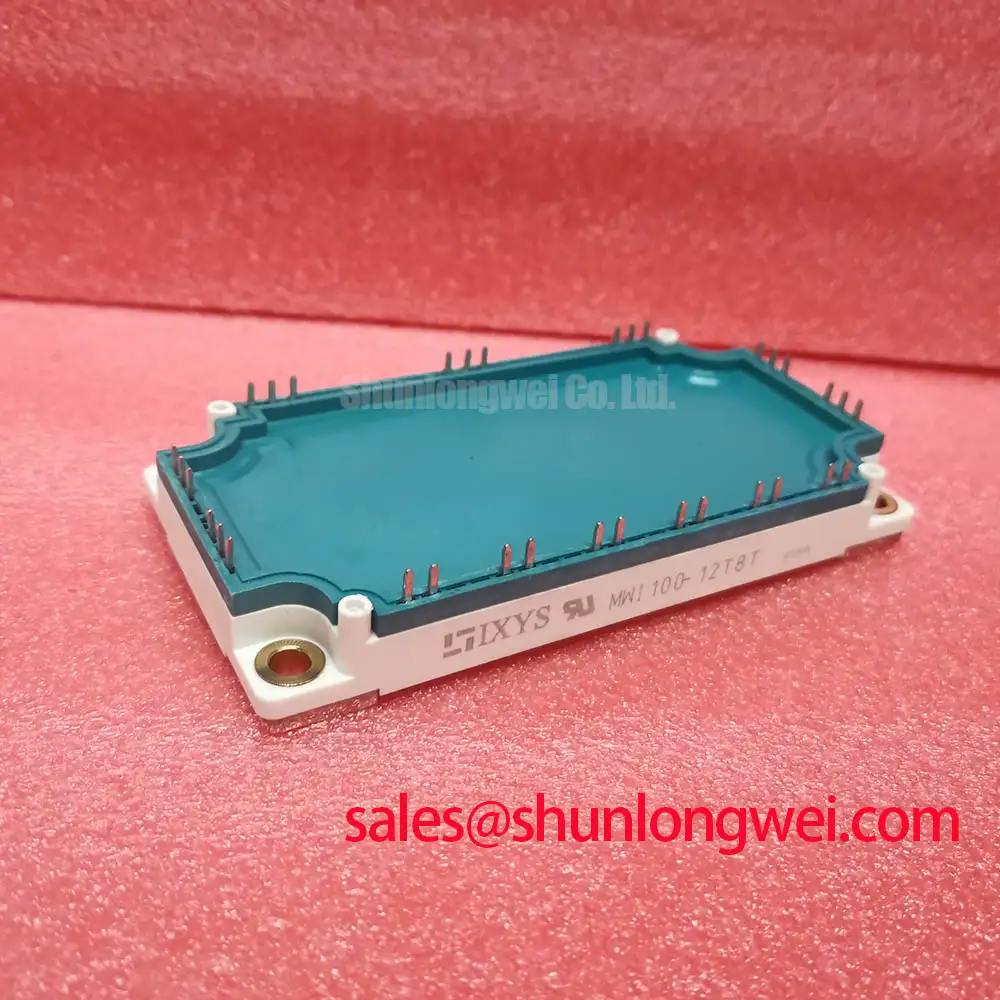

MWI100-12T8T: High-Efficiency 1200V Six-Pack IGBT Module for AC Motor Drives

Introduction to the MWI100-12T8T Power Module

Content last revised on October 5, 2025.

The MWI100-12T8T is a high-performance six-pack IGBT module engineered for efficiency and reliability in three-phase power conversion systems. Leveraging advanced Trench IGBT technology, it delivers optimized switching performance and low conduction losses, making it a robust solution for demanding AC motor drive applications. With core specifications of 1200V | 145A (at 25°C) | VCE(sat) 1.7V, this module provides superior thermal efficiency and robust operational characteristics. Its integrated design simplifies system assembly while the internal NTC thermistor enables precise temperature monitoring for enhanced system protection. For industrial drive systems requiring robust control under variable loads, the MWI100-12T8T's low saturation voltage and fast switching capabilities are a definitive engineering advantage.

Application Scenarios & Value

Achieving System-Level Benefits in Variable Frequency Drives

The MWI100-12T8T is engineered specifically for the core of modern Variable Frequency Drive (VFD) systems, which are essential for controlling the speed and torque of AC motors in industrial automation, HVAC, and pumping applications. What is the primary benefit of its Trench IGBT design? Enhanced power density by minimizing both switching and conduction losses. In a VFD, high efficiency is critical to reduce waste heat, which directly dictates the size of the required heatsink and the overall enclosure volume. The MWI100-12T8T's typical collector-emitter saturation voltage (VCE(sat)) of 1.7V at its nominal current ensures that conduction losses are kept low during motor operation. This is analogous to reducing friction in a mechanical system; less energy is wasted as heat, allowing more power to be delivered to the motor. This efficiency is crucial for meeting stringent energy standards and reducing the total cost of ownership for the end equipment.

For systems that require operation at higher power levels, the related SKM200GB128D offers a higher current rating, providing a scalable option within the 1200V class.

Key Parameter Overview

Decoding the Specs for Efficient Power Conversion

The technical specifications of the MWI100-12T8T are tailored for high-frequency and high-reliability power switching applications. The parameters below highlight its capability to manage demanding electrical and thermal loads. The integration of six IGBTs with anti-parallel diodes in a standard E3-Pack provides a compact and efficient solution for building three-phase inverters.

| Parameter | Symbol | Conditions | Value |

|---|---|---|---|

| Absolute Maximum Ratings (per IGBT) | |||

| Collector-Emitter Voltage | VCES | TJ = 25°C to 150°C | 1200 V |

| Continuous Collector Current | IC25 | TC = 25°C | 145 A |

| Continuous Collector Current | IC80 | TC = 80°C | 100 A |

| Pulsed Collector Current | ICM | TC = 80°C, tp = 1 ms | 200 A |

| Electrical Characteristics (per IGBT at TJ = 25°C) | |||

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 100 A, VGE = 15 V | 1.7 V (typ.) |

| Gate-Emitter Threshold Voltage | VGE(th) | IC = 4 mA | 5.0 - 6.5 V |

| Thermal and Mechanical Characteristics | |||

| Operating Junction Temperature | TVJ | - | -40 to +150 °C |

| Thermal Resistance, Junction-to-Case | RthJC | Per IGBT | 0.26 K/W |

| Package | - | - | E3-Pack |

Download the MWI100-12T8T datasheet for detailed specifications and performance curves.

Technical Deep Dive

Inside the Trench IGBT Technology for Superior Performance

The core of the MWI100-12T8T's performance lies in its use of Trench IGBT technology. Unlike older planar IGBT structures, the trench gate design creates a vertical current path within the silicon. This architectural difference significantly increases the density of charge carriers in the conduction channel, which is the primary reason for the module's low VCE(sat) of 1.7V. A lower VCE(sat) directly translates to lower power dissipation during the on-state, a critical factor in applications like AC motor drives where the inverter is conducting current for extended periods. Think of it as widening a highway; the trench structure allows more current (traffic) to flow with less resistance (congestion), thereby reducing wasted energy (heat). This inherent efficiency allows designers to either push for higher output power within the same thermal budget or reduce the complexity and cost of the cooling system for a given power level.

Frequently Asked Questions (FAQ)

What is the role of the integrated NTC thermistor?

The built-in NTC (Negative Temperature Coefficient) thermistor provides a real-time method for monitoring the module's internal temperature. This data is critical for the drive's control system to implement over-temperature protection, preventing thermal runaway and enhancing the long-term reliability of both the IGBT module and the overall system.

How does the VCE(sat) of 1.7V impact system design for a 100A AC motor drive?

A low VCE(sat) at high current levels directly reduces conduction losses (Power Loss = VCE(sat) x IC). For a 100A drive, this means significantly less heat is generated compared to modules with higher saturation voltages. This allows for the use of smaller, more cost-effective heatsinks and potentially higher power density, enabling more compact overall system designs.

Is the MWI100-12T8T suitable for paralleling to achieve higher current output?

While the datasheet does not explicitly detail paralleling procedures, Trench IGBTs typically exhibit a positive temperature coefficient for VCE(sat). This characteristic helps in balancing current sharing between parallel-connected modules. However, successful paralleling requires careful gate drive design and symmetrical layout to ensure stable operation. Engineers should consult detailed application notes from the manufacturer for guidance on this topic.

Engineering Support and Next Steps

For design engineers and procurement specialists evaluating power modules for motor drives, uninterruptible power supplies, or welding systems, the MWI100-12T8T offers a compelling blend of efficiency, integration, and thermal performance. To further explore its capabilities or discuss its fit within your specific application, please contact our technical sales team for expert consultation and component sourcing support.