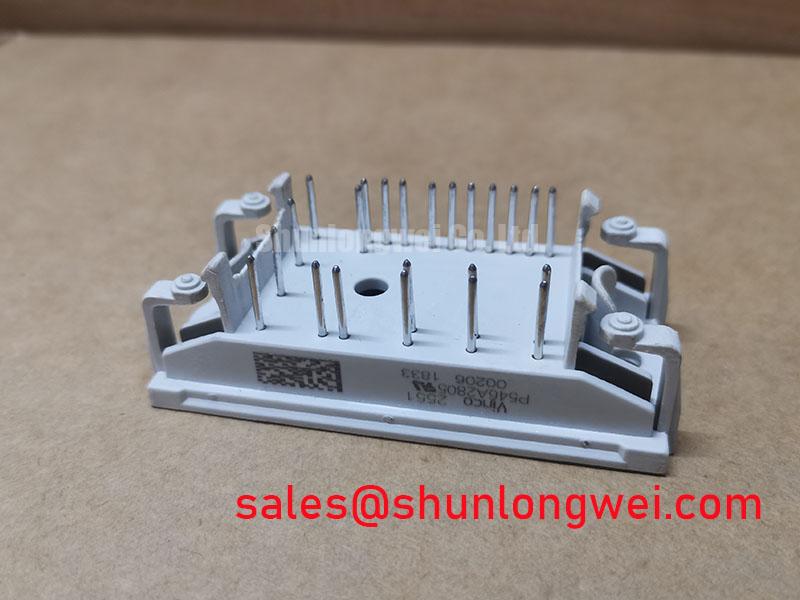

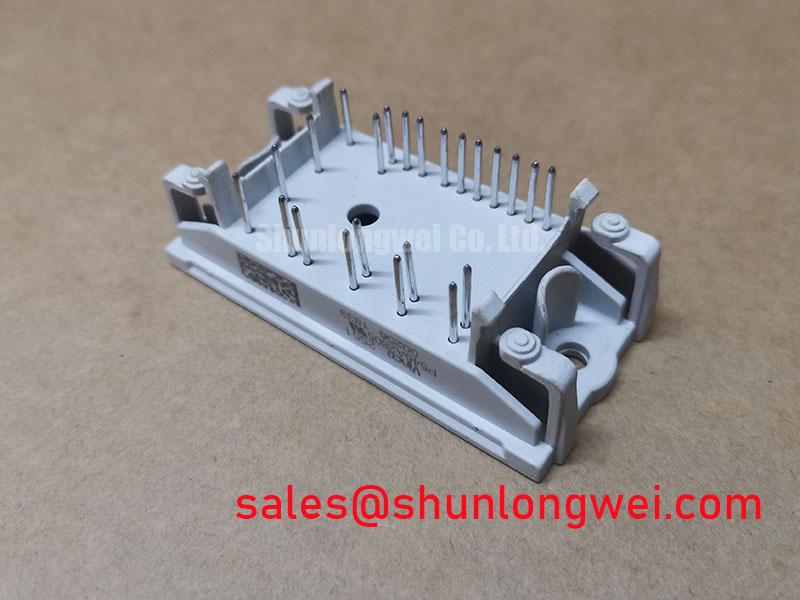

Vincotech P546A2805 | High-Integration 1200V PIM for Compact Motor Drives

The Vincotech P546A2805 is an expertly engineered Power Integrated Module (PIM) designed to streamline the development of compact and efficient motor drives and power conversion systems. By integrating a three-phase input rectifier, a three-phase output inverter, and a brake chopper into a single, thermally efficient flow 1 package, this module dramatically reduces component count, simplifies assembly, and minimizes system footprint. It is the definitive solution for engineers seeking to accelerate time-to-market without compromising on performance or reliability.

- All-in-One Integration: Features a full input rectifier, a brake chopper, and a six-pack inverter stage (CIB - Converter Inverter Brake).

- Robust Performance: Built with trusted Infineon Trenchstop™ IGBT3 technology, offering a superb balance of low conduction losses and switching efficiency.

- Enhanced Control: An integrated Kelvin Emitter pin provides a clean gate drive signal path, enabling precise control and reduced switching losses.

- System Monitoring: Includes an onboard NTC thermistor for accurate, real-time temperature monitoring, crucial for overload protection and system longevity.

Application Scenarios & Engineering Value

The highly integrated nature of the Vincotech P546A2805 delivers tangible benefits across a range of demanding applications. Its design directly addresses common engineering challenges related to space constraints, thermal management, and assembly complexity.

- Variable Frequency Drives (VFDs): For general-purpose motor drives up to 15 kW, the PIM architecture is a game-changer. It replaces multiple discrete components with one module, shrinking the inverter's overall size and reducing manufacturing costs. The robust 1200V rating provides ample design margin for 380-480V AC line applications.

- High-Precision Servo Drives: In applications demanding precise motor control, the module's Kelvin Emitter proves invaluable. By mitigating the effects of stray inductance in the emitter path, it ensures cleaner gate signals, leading to more predictable switching characteristics and improved control loop stability.

- Industrial Power Supplies & UPS: The module's integrated rectifier and brake chopper simplify the design of active front-ends and battery charging/discharging circuits in Uninterruptible Power Supplies (UPS), ensuring a reliable and compact power backbone.

Technical Deep Dive: The Engineering Behind the Performance

The superior performance of the P546A2805 is rooted in its intelligent combination of topology, silicon technology, and packaging. This is not just a collection of components; it's a synergistic system.

PIM Topology Advantage: The core value lies in its Converter-Inverter-Brake (CIB) topology. This consolidates the entire power stage of a standard drive onto a single substrate. For design engineers, this translates directly to a simplified bill of materials (BOM), reduced PCB complexity, faster assembly, and a single, unified interface for thermal management. This approach is fundamental to creating modern, power-dense IGBT modules.

Balanced IGBT3 Silicon: The choice of Infineon's Trenchstop™ IGBT3 technology is deliberate. It is optimized for the switching frequencies typically found in motor drives (2 kHz to 16 kHz). This technology provides a low VCE(sat), which minimizes conduction losses during operation, and controlled switching behavior, which helps manage EMI without incurring excessive switching losses. This balance is critical for achieving high overall system efficiency.

Key Parameter Overview

The following table outlines the critical specifications for design engineers. For a comprehensive dataset, including thermal characteristics and safe operating areas, please download the official P546A2805 datasheet.

| Parameter | Value |

|---|---|

| Max. Collector-Emitter Voltage (VCES) | 1200 V |

| Nominal Collector Current @ TC=80°C (IC,nom) - Inverter | 35 A |

| Nominal Collector Current @ TC=80°C (IC,nom) - Brake Chopper | 50 A |

| Output Current @ TC=80°C (Iout) - Rectifier | 50 A |

| Collector-Emitter Saturation Voltage (VCE(sat)) typ. @ IC,nom | 1.85 V |

| Topology | Sixpack + Brake Chopper + Input Rectifier (PIM) |

| Package | flow 1 (12 mm) |

Engineer's FAQ

How does the integrated topology affect thermal design?

Consolidating three power stages (rectifier, brake, inverter) onto one module centralizes the heat source. This simplifies heatsink design, as you only need to manage one thermal interface. The module's Al2O3 DCB substrate provides excellent electrical isolation and efficient heat transfer to the heatsink, but it's critical to ensure low thermal resistance between the module baseplate and the heatsink for optimal performance, especially under heavy load cycles.

What is the primary benefit of the integrated brake chopper?

In motor drive applications, deceleration or overhauling loads cause the motor to act as a generator, sending energy back to the DC link and raising its voltage. The integrated brake chopper provides a simple and effective way to manage this regenerative energy. It switches in an external braking resistor to dissipate the excess energy as heat, protecting the DC link capacitors and other components from dangerous overvoltage conditions. Having it inside the module eliminates the need for an external chopper circuit, saving space and cost.

For detailed application support or to discuss how the Vincotech P546A2805 can enhance your next project, please contact our technical team.