Content last revised on November 18, 2025

PM200DVA120 IGBT Module: Technical Review for High-Reliability Power Systems

A Distributor's Engineering-First Analysis of the Mitsubishi PM200DVA120

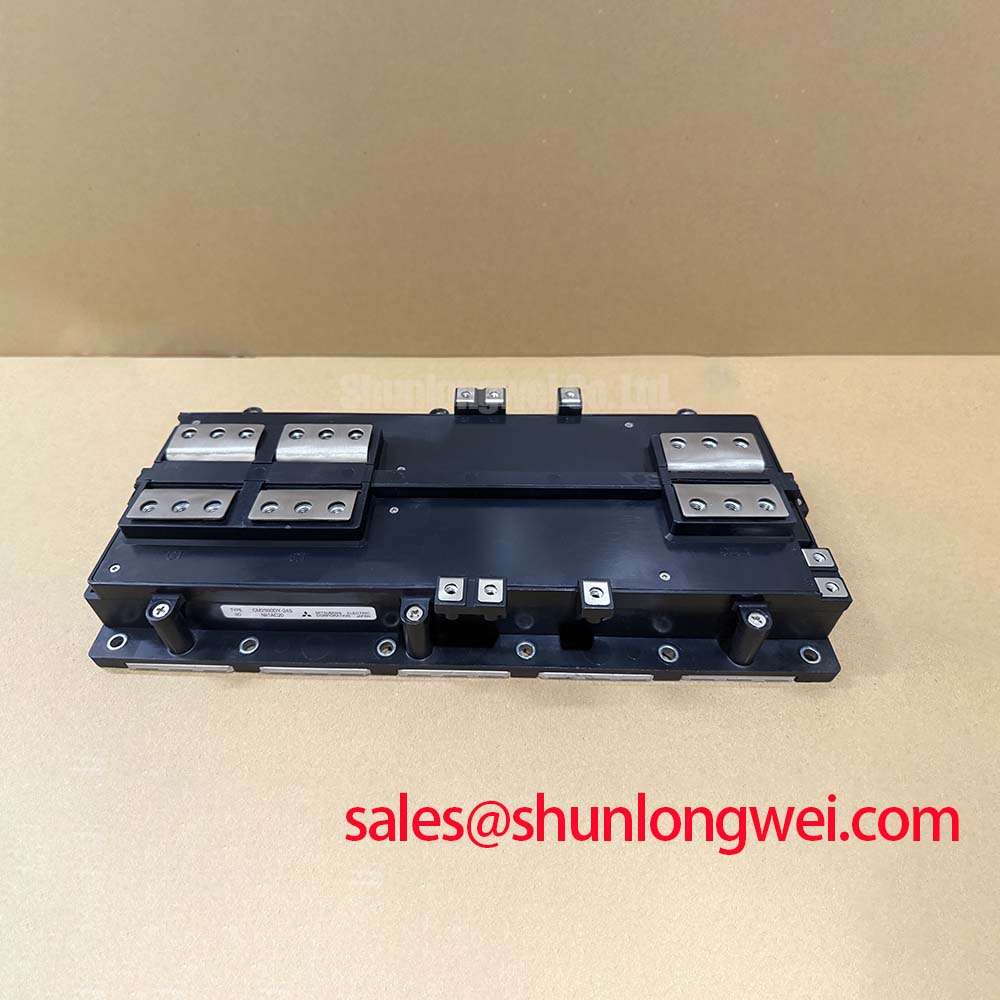

The Mitsubishi PM200DVA120 is a 1200V dual IGBT module engineered for exceptional thermal performance, enabling robust and power-dense designs in high-current industrial chopper and inverter applications. Featuring core specifications of 1200V | 200A | Rth(j-c) 0.12°C/W, this device delivers two primary engineering benefits: enhanced thermal reliability and a simplified layout for chopper circuits. For engineers asking how to effectively manage thermal loads in high-power converters, the module's low junction-to-case thermal resistance provides a direct path to more efficient heat dissipation and improved system longevity. For high-current chopper circuits demanding robust thermal margins, the PM200DVA120's 0.12°C/W Rth(j-c) makes it a strategically sound choice.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The following parameters for the PM200DVA120 are extracted directly from the official datasheet. The engineering value interpretation highlights how each specification influences system-level design and performance.

| Parameter | Symbol | Conditions | Value | Engineering Value & Interpretation |

|---|---|---|---|---|

| Collector-Emitter Voltage | VCES | - | 1200V | Provides a substantial safety margin for applications running on 400V to 690V AC lines, protecting against voltage transients common in industrial environments. |

| Collector Current (DC) | IC | Tc = 25°C | 200A | Supports high-power applications, capable of driving large industrial motors and handling significant continuous loads in power converters. |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 200A, Tj = 125°C | 2.7V (Typ.) | A low VCE(sat) directly translates to lower conduction losses (P = VCE(sat) * IC), which reduces the amount of waste heat generated during operation. |

| Thermal Resistance (Junction to Case, per IGBT) | Rth(j-c) | - | 0.12°C/W | (Critical Parameter) This extremely low thermal resistance signifies a highly efficient heat path from the IGBT chip to the module's baseplate, simplifying Thermal Management and enabling more compact heatsink designs. |

| Isolation Voltage | Viso | AC 1 minute | 2500 Vrms | Ensures robust electrical isolation between the high-power circuitry and the mounting surface, simplifying system integration and adherence to safety standards like IEC 61800-5-1. |

Download the PM200DVA120 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in Industrial Drives and Power Converters

The PM200DVA120 is best suited for high-power DC chopper and single-phase inverter applications where thermal performance and reliability are paramount. Its dual C-type (common collector) configuration makes it a natural fit for these topologies, streamlining the power stage layout.

Consider the design of a 75kW Variable Frequency Drive (VFD) operating within a sealed, compact enclosure. A primary engineering challenge is dissipating the heat generated by the power module to prevent overheating and ensure a long operational life. The PM200DVA120 directly addresses this with its low thermal resistance of 0.12°C/W. This superior thermal characteristic allows engineers to either specify a smaller, more cost-effective heatsink or to run the drive at a higher power output in elevated ambient temperatures without exceeding the maximum junction temperature. This capability is crucial in demanding industrial settings where space is limited and reliability cannot be compromised. What is the primary benefit of its low thermal resistance? It enables higher power density and improved long-term reliability.

For systems that require even greater current handling capacity within a similar voltage class, the related PM300DVA120 offers a 300A rating while maintaining a comparable package footprint.

Frequently Asked Questions (FAQ)

How does the PM200DVA120's low Rth(j-c) of 0.12°C/W impact heatsink design and system costs?

A low thermal resistance means heat is transferred away from the IGBT chip more effectively. This allows for the use of a smaller, lighter, and less expensive heatsink to maintain the same operating temperature. Alternatively, it provides a greater thermal margin, enhancing system reliability and lifetime under harsh load cycles.

What is the primary advantage of the "Dual C-Type" (common collector) configuration in the PM200DVA120?

This configuration is optimized for DC chopper circuits, brake choppers in drives, or one leg of a single-phase inverter. It simplifies the PCB layout and busbar design by providing a common collector connection point, which can help reduce stray inductance compared to using two discrete IGBT modules.

What are the typical applications for a 1200V, 200A IGBT module like this?

This module is engineered for high-power industrial applications, including motor drives (VFDs), servo drives, power supplies for welding equipment, UPS (Uninterruptible Power Supply) systems, and solar or wind power inverters operating on higher voltage DC buses.

Are there specific considerations for the gate drive circuit for the PM200DVA120?

Yes, the datasheet specifies a recommended gate-emitter voltage (VGE) of +15V for turn-on and -5V to -10V for turn-off. Using a negative gate voltage is crucial for ensuring rapid and clean turn-off and preventing parasitic turn-on, especially in noisy industrial environments. A robust gate drive design is essential for minimizing switching losses and ensuring safe operation.

How does the 2500Vrms isolation voltage benefit system safety?

This high isolation rating provides a certified dielectric barrier between the high-voltage power circuit and the module's baseplate, which is typically mounted to a grounded heatsink. This prevents hazardous voltages from reaching the chassis, ensuring the safety of equipment and personnel and simplifying compliance with international safety standards.

Technical Deep Dive

A Closer Look at Thermal Design for Long-Term Reliability

The reliability of a high-power module like the PM200DVA120 is inextricably linked to its thermal design. The specified Rth(j-c) of 0.12°C/W is not just a number; it's a critical indicator of the module's internal construction quality and its ability to withstand demanding operational stress. Think of Rth(j-c) as the width of a highway for heat. A low value, like this module's 0.12°C/W, represents a wide, multi-lane superhighway, allowing thermal energy to escape the silicon chip quickly and preventing the "traffic jams" of heat that lead to junction overheating and eventual failure.

This superior thermal pathway is achieved through careful material selection and manufacturing processes within the Mitsubishi module, including the direct bonding of the silicon to a high-conductivity ceramic substrate and an optimized copper baseplate. For a design engineer, this means that for every watt of power lost as heat, the IGBT junction temperature will only rise by 0.12°C above the case temperature. This efficiency provides a larger operational margin, directly improving the module's power cycling capability and extending its service life in applications like motor drives that experience frequent start/stop cycles.

An Engineer's Perspective on Application Fit

From a system design standpoint, the PM200DVA120 presents a compelling case for applications where thermal density is a key design constraint. While raw switching speed or the lowest possible VCE(sat) might be the deciding factors in some ultra-high-frequency designs, this module's strength lies in its thermal robustness. It allows engineers to push power levels higher within a given form factor or to design systems with greater tolerance for harsh ambient conditions. This focus on thermal reliability makes the PM200DVA120 a workhorse component for building dependable and durable industrial power conversion systems. When long-term operational stability is as critical as electrical performance, this module's thermal characteristics should be a primary consideration in the component selection process.