Content last revised on December 11, 2025

An Engineer's Review of the SKD145/12 Rectifier Module

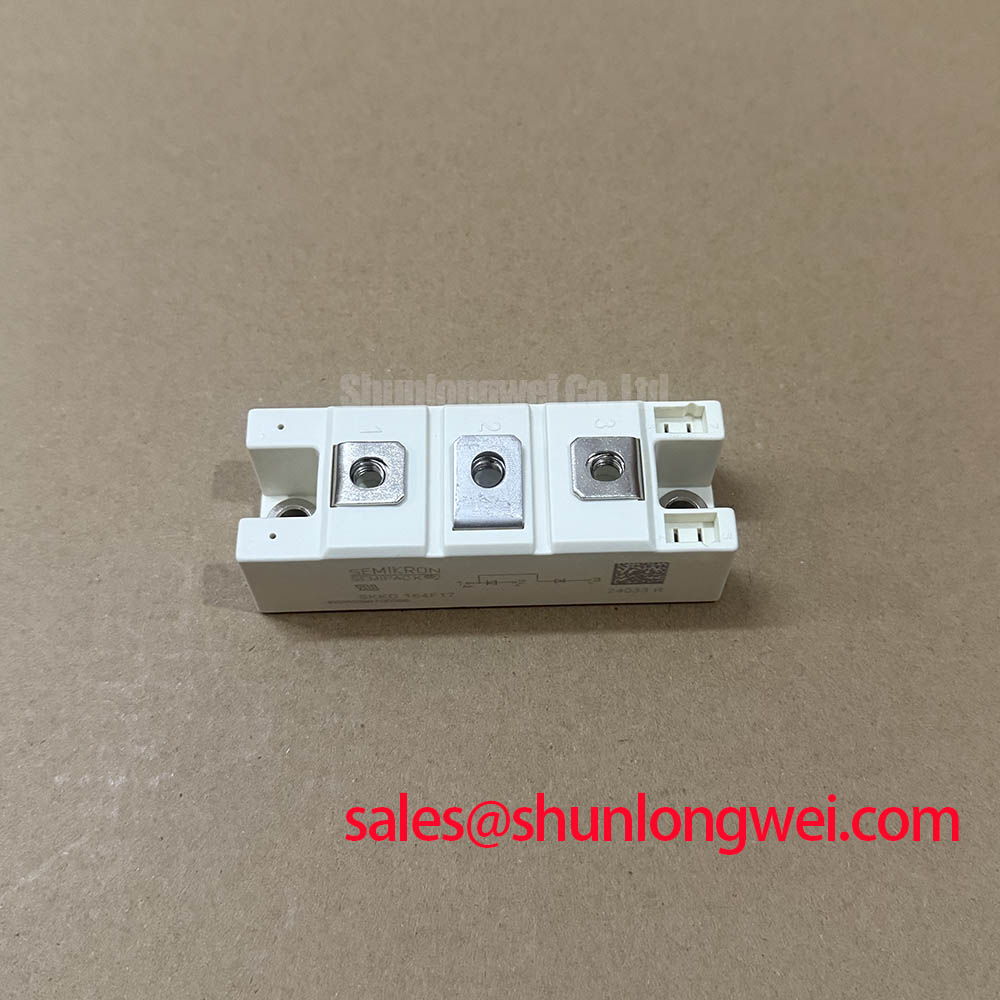

SKD145/12: A SEMIKRON Three-Phase Bridge Rectifier for High-Reliability Power Conversion

The SEMIKRON SKD145/12 is a high-performance three-phase uncontrolled bridge rectifier module engineered for efficiency and long-term reliability in demanding industrial power systems. With its core specifications of 1200V | 140A | Low Rth, this module from the SEMIPONT 5 series delivers a robust front-end rectification solution. Key engineering benefits include superior thermal performance via a direct bonded copper (DBC) substrate and exceptional resilience to surge currents. For designers building input stages for variable frequency drives or industrial power supplies, the SKD145/12 directly addresses the challenge of achieving reliable power conversion with simplified thermal management. For systems that demand robust performance with a significant safety margin on 400V AC lines, this 1200V module is the optimal choice.

Application Scenarios & Value

Delivering System-Level Dependability in Industrial Drive and Power Supply Rectification

The SEMIKRON SKD145/12 is fundamentally engineered for the input stages of power conversion systems where operational reliability is non-negotiable. Its primary role is to convert three-phase AC input into a stable DC voltage, forming the foundation for a dependable DC bus. A high-fidelity engineering scenario is its deployment in the front-end of a Variable Frequency Drive (VFD) controlling a mid-power industrial motor. During motor startup or under fluctuating load conditions, the power line can experience significant stress. The SKD145/12's high surge current rating (IFSM = 1800 A at 25 °C) ensures it can withstand these intense, short-duration transients without degradation, directly preventing costly system failures and downtime.

The module's design, which uses a direct bonded copper substrate for isolation, provides both excellent heat transfer and a high isolation voltage (Visol = 3000V~), simplifying system-level safety compliance and mounting within various industrial enclosures. This module is optimized for systems including:

- AC Motor Drives and Soft Starters

- Industrial Power Supply Units (PSUs)

- Uninterruptible Power Supply (UPS) Systems

- Battery Charging Systems and Rectifiers

While the SKD145/12 is ideal for a wide range of standard industrial applications, for systems requiring higher current handling capabilities, the related SKD160/16 offers an increased current rating within a similar package family.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The performance of the SKD145/12 is defined by a set of electrical and thermal characteristics that are critical for system design. These parameters, drawn from the official datasheet, provide the engineering basis for its integration into high-reliability applications.

| Electrical Ratings @ Tj = 125 °C unless otherwise specified | |

| Repetitive Peak Reverse Voltage (VRRM) | 1200V |

| DC Output Current (ID) at Ts = 85 °C | 140A |

| Peak Forward Surge Current (IFSM) at Tvj=25°C, 10ms | 1800A |

| Forward Voltage (VF) at IF = 150A | max. 1.3V |

| Thermal and Mechanical Ratings | |

| Thermal Resistance, Junction to Heatsink (Rth(j-s)) | 0.8 K/W (per diode) |

| Max. Junction Temperature (Tvj max) | 150°C |

| Isolation Voltage (Visol) | 3000V (a.c., 50 Hz, r.m.s, 1 min) |

| Package | SEMIPONT 5 |

Download the SKD145/12 datasheet for detailed specifications and performance curves.

Technical Deep Dive

A Closer Look at the DBC Substrate and its Impact on Longevity

A defining feature of the SEMIKRON SKD145/12 is its use of a Direct Bonded Copper (DBC) substrate for heat transfer and electrical isolation. Unlike traditional modules that rely on a metal baseplate with a separate isolation layer, the DBC construction integrates these functions into a single, highly efficient component. This design choice has significant engineering implications. The thermal resistance per diode is specified at 0.8 K/W, a testament to the efficient thermal path from the silicon diode to the heatsink. This is analogous to using a wider, shorter pipe to drain heat away from the active components, allowing the module to run cooler under heavy loads or enabling the use of a smaller, more cost-effective heatsink for the same operating temperature.

Furthermore, this construction enhances mechanical reliability. By eliminating the solder layer between a baseplate and the substrate, a potential point of failure due to thermal cycling fatigue is removed. In applications like motor drives, which frequently start, stop, and change speed, the resulting temperature fluctuations can stress mechanical bonds over time. The integrated DBC design of the SKD145/12 creates a more robust structure, contributing to a longer operational lifespan. For engineers, this translates directly to a more reliable system with a lower total cost of ownership. For a deeper understanding of how thermal management impacts component life, a review of advanced thermal management techniques is beneficial.

Frequently Asked Questions

Engineering Queries on the SKD145/12

What is the primary benefit of the module's 1800A surge current rating?

The high IFSM rating ensures the rectifier can survive the large inrush currents that occur when charging the DC bus capacitors in VFDs or PSUs, a critical factor for long-term system reliability.

How does the direct bonded copper (DBC) design affect thermal management?

The DBC substrate provides a low thermal resistance path (Rth(j-s) of 0.8 K/W per diode), allowing for more efficient heat dissipation. This enables either lower operating temperatures for the diodes, increasing their lifespan and reliability, or the use of a smaller heatsink, which saves space and cost in the final system design.

Streamlining Your Power Conversion Design

For engineers and procurement managers focused on developing reliable and thermally efficient power conversion systems, the SEMIKRON SKD145/12 presents a compelling solution. Its robust electrical characteristics, combined with a design optimized for effective thermal management, make it a premier choice for the input rectification stage of industrial drives, power supplies, and battery chargers. To evaluate this module for your next project or to secure it for your production line, please reach out to our technical sales team for a quotation and to discuss your application requirements.