Content last revised on November 21, 2025

SKKD 75F12 Fast Diode Module: Engineered for High-Frequency and Reliable Power Conversion

An Introduction to the SKKD 75F12 Diode Module

Engineered for Thermal Stability and Long-Term Reliability in Demanding Power Systems

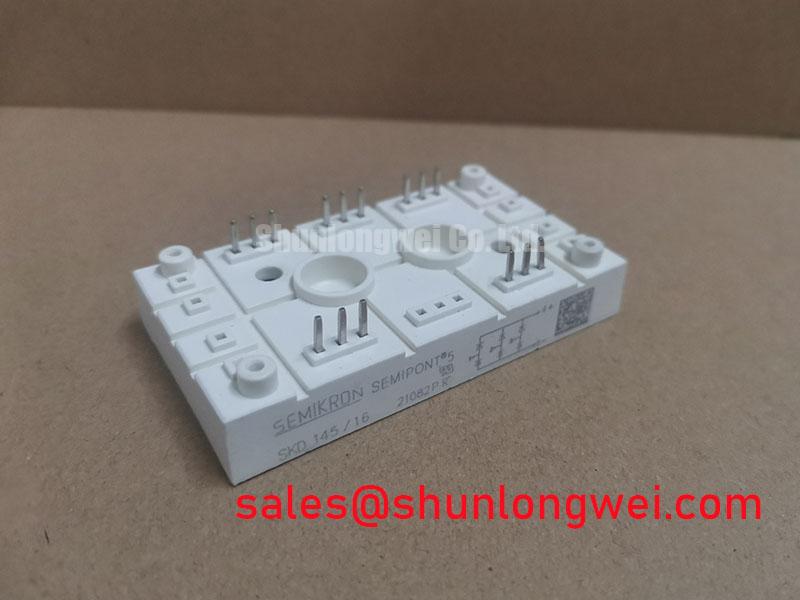

The SKKD 75F12 is a fast diode module designed for high-reliability power conversion, delivering robust performance through superior thermal management and a durable mechanical design. With core specifications of 1200V | 75A | Rth(j-c) 0.2 K/W (per module), this component is built to ensure operational stability. Key engineering benefits include enhanced heat dissipation via an isolated baseplate and predictable, soft recovery characteristics. It directly addresses the need for a resilient rectification stage in industrial systems that experience frequent thermal and electrical stress. For power systems requiring higher current handling while maintaining the 1200V rating, the related SKKD162/16 offers a forward current capability of up to 162A.

Key Parameter Overview

Decoding Electrical and Thermal Specs for Robust Rectifier Design

The technical specifications of the SKKD 75F12 are foundational to its performance in high-frequency and high-stress applications. The module's low thermal resistance is a critical asset; the Rth(j-c) of 0.2 K/W per module ensures that heat generated within the silicon die is efficiently transferred to the heatsink. This is analogous to having a wider pipe for water flow—the lower resistance allows more thermal energy to escape, preventing the device from overheating and enhancing its operational lifespan. A high surge current rating (IFSM) of 900A at 150°C Tj underscores its ability to withstand significant inrush currents, a common challenge in motor drives and power supply applications.

| Key Technical Specifications for SKKD 75F12 | ||

|---|---|---|

| Parameter | Value | Conditions |

| Electrical Characteristics | ||

| Repetitive Peak Reverse Voltage (VRRM) | 1200 V | - |

| Average Forward Current (IFAV) | 75 A | sin. 180; 50 Hz; Tc = 55 °C |

| Surge Forward Current (IFSM) | 900 A | Tvj = 150 °C; 10 ms |

| I²t Value | 4000 A²s | Tvj = 150 °C; 8,3 ... 10 ms |

| Maximum Forward Voltage (VF) | 2.2 V | Tvj = 25 °C; IF = 75 A |

| Thermal and Mechanical Characteristics | ||

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.2 K/W | Per module |

| Operating Junction Temperature (Tvj) | -40 to +150 °C | - |

| Isolation Voltage (Visol) | 4000 V~ | a.c. 50 Hz; r.m.s.; 1 min |

Download the SKKD 75F12 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Enhancing System Reliability in Drives, Power Supplies, and Welding Systems

The SKKD 75F12 is optimized for a range of demanding power applications where both efficiency and durability are non-negotiable. Its architecture is particularly well-suited for the input rectification stages of industrial systems. A prime example is its use in a Variable Frequency Drive (VFD). In this scenario, the VFD's DC bus capacitor presents a near short-circuit upon startup, drawing a massive inrush current. The SKKD 75F12's high I²t value of 4000 A²s ensures it can reliably handle this repetitive stress without degradation, a critical factor for the drive's long-term reliability. Furthermore, its CAL ("controlled axial lifetime") technology provides soft recovery characteristics, which minimizes voltage overshoots and electromagnetic interference (EMI), simplifying system-level filtering and compliance. This combination of robustness and clean switching makes it a strong candidate for:

- AC Motor Speed Control

- Uninterruptible Power Supplies (UPS)

- Electronic Welding Equipment

- DC Choppers and Switched-Mode Power Supplies

- Inductive Heating Systems

These applications benefit directly from the module's ability to maintain stable operation under harsh electrical conditions, as detailed in guides on unlocking thermal performance.

Technical & Design Deep Dive

Inside the A23 Housing: An Analysis of the Isolated Baseplate and Solder Technology

A key differentiator of the SKKD 75F12 lies in its physical construction, which is engineered for thermal efficiency and simplified system integration. The module utilizes a ceramic isolated metal baseplate, a design choice with significant engineering implications. The ceramic layer, typically Aluminium Oxide (Al2O3), provides excellent electrical isolation (rated up to 4000V AC), allowing multiple modules to be mounted on a single, non-isolated heatsink without the need for additional insulating pads. This not only reduces assembly complexity and component count but also improves thermal transfer by eliminating an extra interface layer. Think of it as removing a layer of clothing on a hot day; the direct contact facilitates better cooling. This design is crucial for achieving the low thermal resistance values specified in the datasheet, which is a cornerstone of reliable power electronics design. For engineers, this translates to more compact and cost-effective thermal solutions.

Frequently Asked Questions (FAQ)

What is the engineering benefit of the electrically isolated baseplate on the SKKD 75F12?

The primary benefit is simplified thermal management and system assembly. It allows the module to be mounted directly onto a common, earthed heatsink without requiring external insulating materials, reducing both thermal resistance and assembly costs while ensuring high electrical isolation of 4000V.

How does the module's thermal resistance (Rth(j-c)) influence the thermal design for a 3-phase rectifier?

A lower Rth(j-c), such as the 0.2 K/W per module of the SKKD 75F12, directly enables a more compact and cost-effective heatsink design. It signifies that heat flows more easily from the active semiconductor junction to the module case, resulting in a lower operating junction temperature for a given power dissipation. This provides engineers with a greater thermal margin, enhancing system reliability, especially in high-ambient-temperature environments.

To further explore the principles of component selection based on datasheets, consider this practical guide for engineers. For technical inquiries or to discuss sourcing for your next project, please reach out to our team for engineering-level support.