Content last revised on January 10, 2026

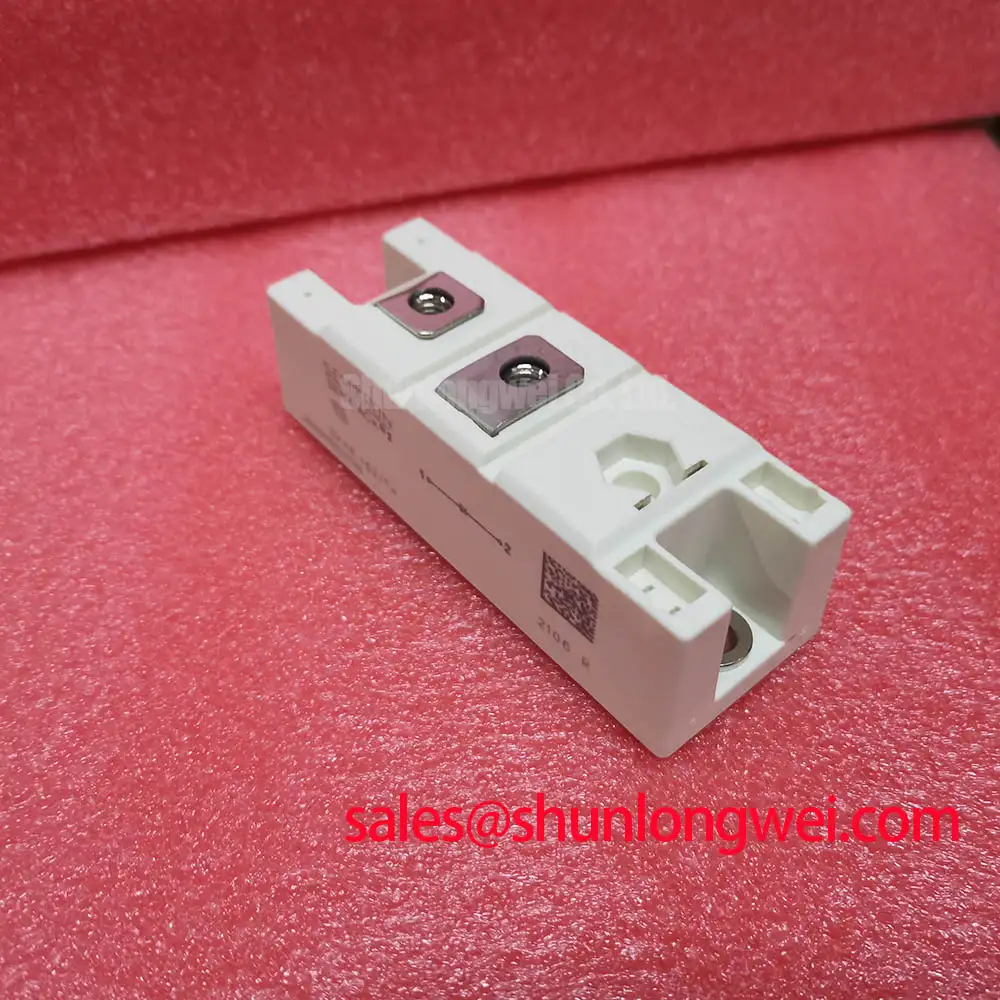

SKKE162/16: High-Reliability 1600V Thyristor/Diode Module for Demanding Power Control

Engineering Insights for Long-Term System Performance

The SKKE162/16 is a thyristor/diode module engineered for exceptional long-term reliability in high-stress industrial power conversion systems. It combines robust electrical characteristics—1600V | 160A | I²t = 200 kA²s—with a superior mechanical design to ensure operational stability. Key engineering benefits include exceptional power cycling capability and high surge current immunity. This module directly addresses the need for components that can withstand harsh industrial environments without degradation, a critical factor for systems requiring high uptime. For applications demanding robust control on 690V AC lines, the SKKE162/16 provides the necessary voltage headroom and thermal stability.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The electrical and thermal specifications of the SKKE162/16 are foundational to its performance in demanding applications. The following parameters highlight its suitability for high-reliability designs where thermal management and fault tolerance are critical engineering considerations.

| Parameter | Value | Engineering Value & Interpretation |

|---|---|---|

| Repetitive Peak Reverse Voltage (VRRM) | 1600 V | Provides substantial safety margin for operation on industrial 3-phase lines, including 690V systems, protecting against line voltage transients. |

| On-state Current (IT(AV)) @ Tc=85°C | 160 A | Indicates a strong continuous current handling capability, suitable for high-power rectifiers and motor control applications. |

| I²t value for fusing | 200 kA²s | This high value signifies excellent surge current survivability, allowing the module to withstand significant non-repetitive inrush currents during motor starts or fault conditions. |

| Threshold Voltage (VT(TO)) | 0.9 V | A key parameter for calculating conduction losses and ensuring accurate thermal modeling for the target application. |

| Slope Resistance (rT) | 1.5 mΩ | The low slope resistance contributes to minimal on-state voltage drop and reduced power dissipation, enhancing overall system efficiency. |

| Thermal Resistance, Junction to Case (Rth(j-c)) | 0.160 °C/W (per thyristor/diode) | A critical indicator of efficient heat transfer from the semiconductor junction to the case, simplifying heatsink design and enabling higher power density. |

| Isolation Test Voltage (VISOL) | 3000 V (50 Hz, 1 min.) | Confirms robust electrical isolation between the terminals and the baseplate, crucial for system safety and compliance with standards like IEC 60747. |

Download the SKKE162/16 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in Industrial Power Conversion

The SKKE162/16 is optimized for power control circuits where reliability and precise control are non-negotiable. Its primary value is demonstrated in applications that experience frequent thermal cycling or are subject to significant electrical stress.

A high-fidelity engineering scenario is its use in an AC Motor Softstarter for heavy machinery, such as industrial conveyors or large pump systems. During motor startup, massive inrush currents can stress or destroy less robust components. The SKKE162/16's high I²t rating of 200 kA²s acts as a crucial defense, allowing it to absorb this energy without failing. This ensures a reliable startup sequence, reduces mechanical stress on the drivetrain, and prevents costly downtime. Its pressure-contact design further enhances its suitability for such applications by preventing solder fatigue failures caused by the repeated thermal fluctuations of start/stop cycles. The hermetically sealed case ensures this reliability is maintained even in dusty or humid factory environments.

- DC power supplies for industrial processes

- Controlled and half-controlled rectifiers

- AC motor softstarters and controllers

- Battery charging systems

- Crowbar protection circuits

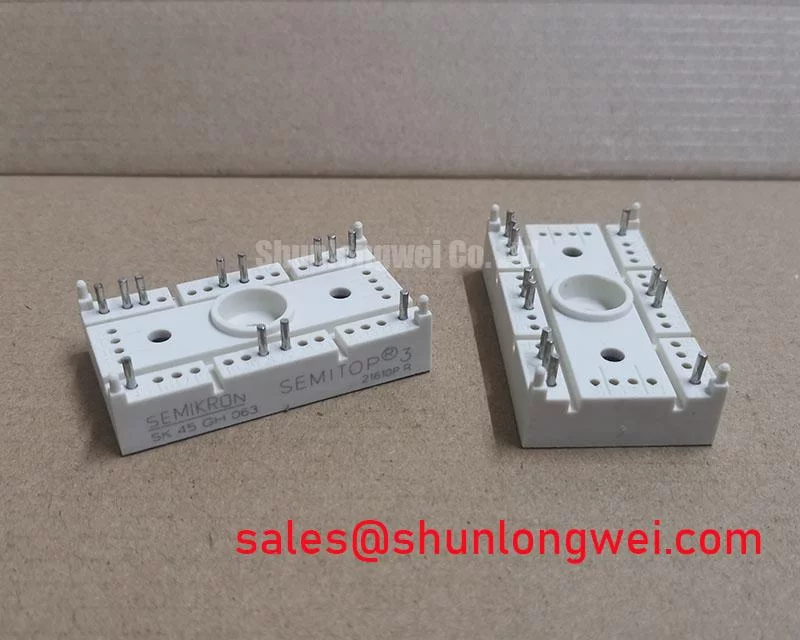

For systems requiring only uncontrolled rectification, the related SKKD162/16 diode module offers a similar robust construction in a diode-diode configuration.

Technical Deep Dive

A Closer Look at Pressure-Contact Design for Long-Term Reliability

A defining feature of the SKKE162/16 is its implementation of Semikron's pressure-contact technology. Unlike conventional modules that rely on soldered connections between the semiconductor die and the baseplate, this design uses a precisely calibrated clamping force to create the electrical and thermal contact. This seemingly simple difference has profound implications for the module's operational lifespan, particularly in applications with significant temperature swings.

Think of a soldered joint like a rigid glue bond between two materials that expand and contract at different rates (the silicon chip and the copper baseplate). Over thousands of cycles of heating and cooling, this bond becomes brittle and can develop micro-cracks, eventually leading to thermal failure. The pressure-contact system works more like a spring-loaded press. As the materials expand and contract, the spring system maintains a consistent, reliable contact. This effectively eliminates solder fatigue as a primary failure mechanism, dramatically increasing the module's Power Cycling Capability and ensuring predictable performance over many years of service.

Industry Insights & Strategic Advantage

Building Resilient Systems for the High Demands of Modern Industry

In the context of industrial automation and critical infrastructure, component failure is not just an inconvenience; it can halt production lines, disrupt essential services, and incur significant financial losses. The design philosophy of the SKKE162/16 directly supports the industry's push towards higher operational availability and reduced total cost of ownership. The combination of its hermetically sealed metal and ceramic case with the internal pressure-contact design creates a formidable barrier against common industrial failure vectors such as humidity, corrosive agents, and mechanical vibration.

This level of intrinsic robustness is critical for equipment like high-power Welding Equipment or uninterruptible power supplies (UPS) for data centers, where consistent performance under adverse conditions is paramount. The high surge current capability (I²t) can be compared to a dam's spillway capacity; it's an engineered safety feature designed to handle rare but potentially catastrophic events, ensuring the entire system's integrity. By specifying a component with such a high tolerance, engineers can build more resilient systems that require less frequent maintenance and offer a longer service life, providing a clear strategic advantage in a competitive market.

Frequently Asked Questions (FAQ)

What is the primary benefit of the pressure-contact technology in the SKKE162/16?

Its key advantage is significantly enhanced long-term reliability. By eliminating solder layers, it circumvents the common failure mode of solder fatigue caused by thermal cycling, making it ideal for applications with frequent on/off cycles.

How does the hermetic metal case with a ceramic insulator contribute to the module's performance?

This construction provides a robust, airtight seal that protects the internal semiconductor elements from environmental contaminants like moisture, dust, and corrosive gases. This is critical for ensuring stable operation and a long service life in harsh industrial settings.

Is the 1600V rating of the SKKE162/16 suitable for 690V AC line applications?

Yes, the 1600V repetitive peak reverse voltage (VRRM) provides a substantial safety margin for direct use in rectifiers on 690V industrial AC lines, accommodating the high peak voltages and potential transients present in such systems.

How does the Rth(j-c) of 0.160 °C/W impact thermal design?

This low thermal resistance value indicates very efficient heat transfer from the silicon chip to the module's baseplate. For a design engineer, this means a smaller, less expensive heatsink may be required to maintain a safe operating junction temperature, which can help reduce overall system size, weight, and cost.

What does the I²t rating of 200 kA²s signify for system protection?

This value represents the module's ability to withstand a massive, short-duration, non-repetitive surge of current. It is a critical parameter for coordinating with fuses, ensuring that in a fault scenario, the fuse will blow before the thyristor module is destroyed, thus protecting the more valuable component and simplifying repairs.

An Engineer's Perspective on Component Selection

Selecting the SKKE162/16 is a decision rooted in designing for longevity and resilience. While its core electrical specifications are robust, its true value lies in the mechanical engineering that underpins its performance. For systems deployed in challenging environments or those where maintenance is difficult and uptime is paramount, the investment in a component built with pressure-contact technology and hermetic sealing provides a quantifiable return through reduced field failures and a lower total cost of ownership over the system's entire lifecycle.