Content last revised on November 17, 2025

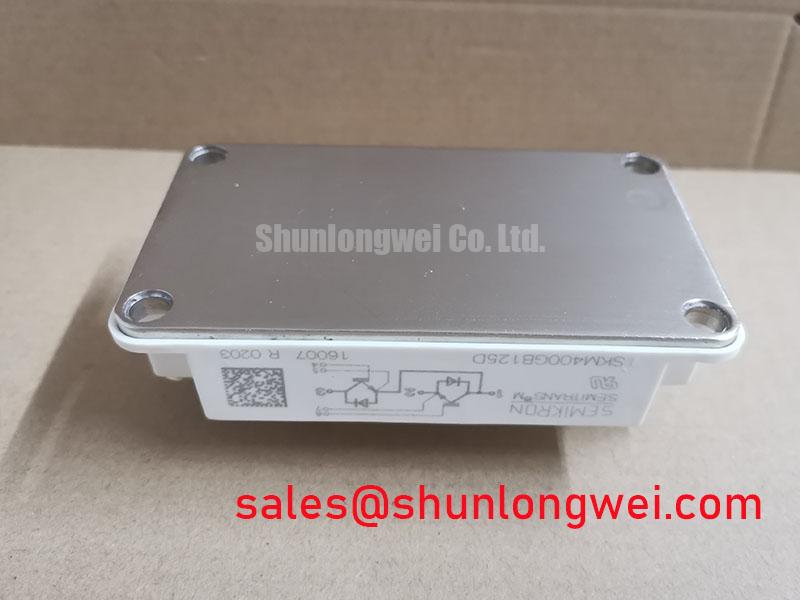

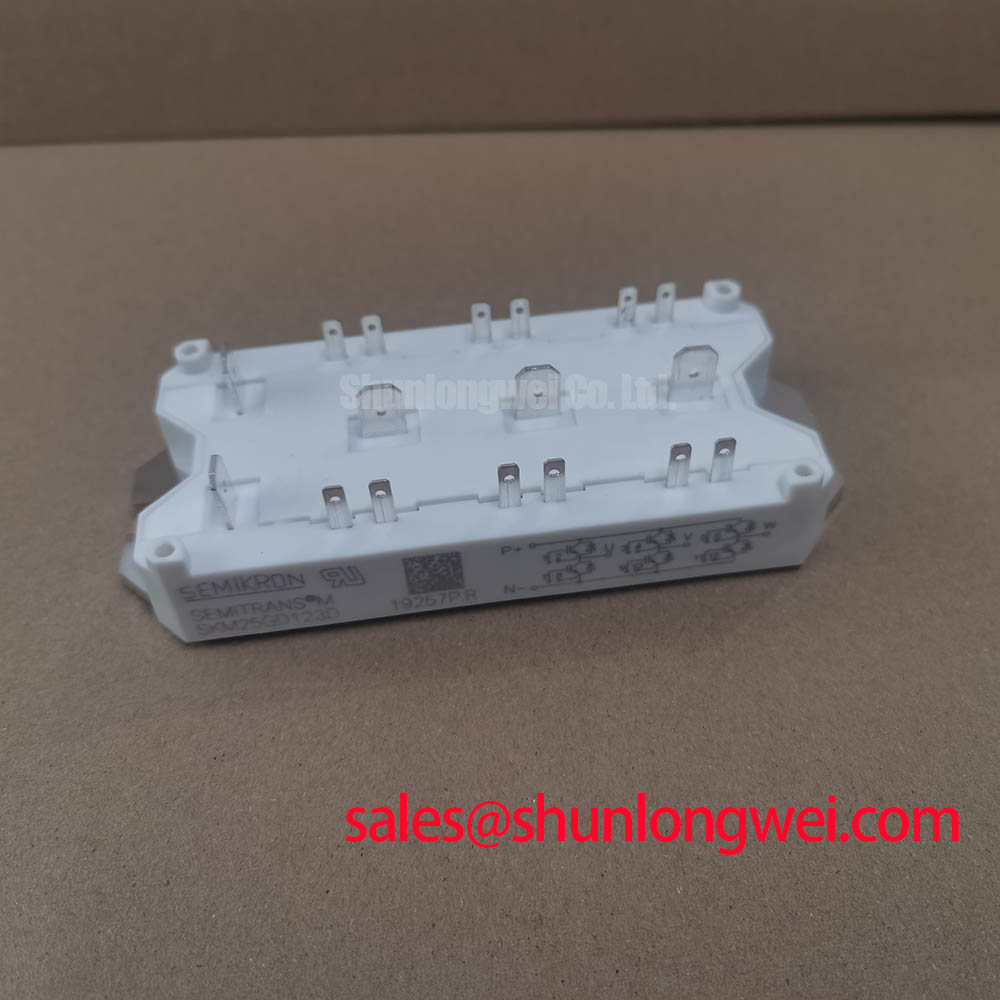

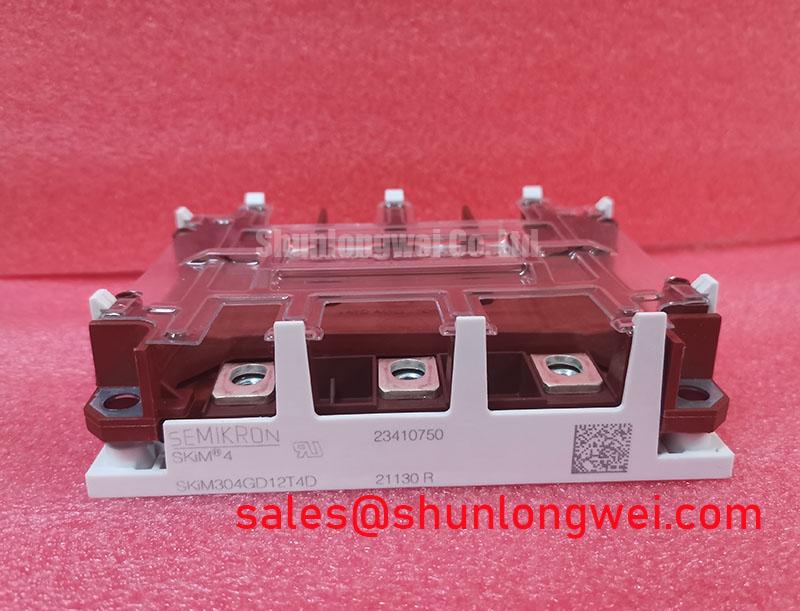

SKM400GB125D SEMITRANS 3 IGBT Module: Engineering for High-Frequency Power Conversion

Introduction and Key Specifications

The SKM400GB125D is a SEMITRANS 3 half-bridge module from Semikron Danfoss, engineered for demanding high-frequency applications. It delivers exceptional efficiency by combining ultra-fast Non-Punch-Through (NPT) IGBTs with advanced, soft-recovery freewheeling diodes. With core specifications of 1200V | 300A | VCE(sat) (typ) 2.1V, this module provides a robust foundation for next-generation power converters. Key benefits include significantly reduced switching losses and enhanced system reliability. For engineers designing systems like resonant inverters up to 100 kHz, its low tail current and optimized diode performance are critical for achieving both high efficiency and robust operation under demanding load cycles. For high-power systems requiring a higher current rating but similar voltage characteristics, the related SKM600GB12M7 offers an alternative path for scalability.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

The SKM400GB125D is optimized for power systems where switching speed is a primary design driver. Its characteristics make it a prime candidate for applications that operate well above the standard mains frequency, enabling designers to reduce the size and cost of magnetic components and improve dynamic response.

- Electronic Welding Power Supplies: In high-frequency welders operating above 20 kHz, the challenge is to manage switching losses which directly translate into heat. The SKM400GB125D's short tail current, which has minimal temperature dependence, is a crucial feature. This ensures that switching-off losses (E_off) remain low even as the device heats up during operation, leading to a more reliable and efficient welding arc control system.

- Inductive Heating Systems: These systems rely on high-frequency resonant circuits to generate heat. The module's integrated "fast & soft" inverse CAL diodes are essential here. Their soft recovery characteristic minimizes voltage overshoot and reduces EMI, simplifying the design of snubber circuits and ensuring the system meets stringent electromagnetic compatibility (EMC) standards.

- Switched-Mode Power Supplies (SMPS): For high-power SMPS, efficiency is paramount. The ultra-fast NPT IGBTs allow for higher switching frequencies, which in turn permits the use of smaller inductors and capacitors, increasing the power density of the overall unit.

- Resonant Inverters: In resonant topologies, where zero-voltage switching (ZVS) or zero-current switching (ZCS) is employed, the fast and clean switching behavior of the SKM400GB125D is critical for minimizing transition losses and maximizing the efficiency of inverters running at up to 100 kHz.

Key Parameter Overview

Decoding the Specs for Efficient High-Frequency Operation

The following parameters are critical for evaluating the SKM400GB125D's performance in its target applications. The values presented here are based on the official manufacturer's documentation and are intended to provide a technical snapshot for engineering assessment.

| Parameter | Value | Engineering Value |

|---|---|---|

| Collector-Emitter Voltage (VCES) | 1200 V | Provides a substantial safety margin for applications running on 400V to 575V AC lines, ensuring reliability against voltage transients. |

| Continuous Collector Current (IC) @ Tcase=80°C | 300 A | Delivers high power handling capability, suitable for inverters and power supplies in the 100-150 kW range. |

| Collector-Emitter Saturation Voltage (VCE(sat)) (typ. @ ICnom, Tj=125°C) | 2.1 V | Indicates low conduction losses. Think of this as the "voltage toll" for current to pass through; a lower value means less power is wasted as heat during the on-state. |

| Total Switching Energy (Ets) (typ. @ ICnom, Tj=125°C) | 48 mJ | This is the energy consumed during each on-off cycle. The low value is a direct result of the ultra-fast IGBT and CAL diode, critical for efficiency in high-frequency designs. |

| Thermal Resistance, Junction-to-Case (Rth(j-c)) per IGBT | ≤ 0.08 K/W | Represents how effectively heat can be transferred from the silicon chip to the module's baseplate. A lower value signifies superior thermal performance, simplifying heatsink design. |

| Short Circuit Withstand Time (tsc) @ VGE ≤ 15V | 10 µs | Defines the module's ruggedness. It can survive a direct short-circuit for 10 microseconds, providing ample time for protection circuits to engage. |

For a comprehensive understanding of all electrical and thermal characteristics, please refer to the official datasheet.

Download the SKM400GB125D datasheet for detailed specifications and performance curves.

Technical Deep Dive

The Engineering Advantage of CAL Diodes and Low Tail Current

Two features of the SKM400GB125D are pivotal for its high-frequency performance: the CAL (Controlled Axial Lifetime) freewheeling diodes and the short tail current. The "tail current" in an IGBT is a lingering flow of current during the turn-off phase. Imagine it like a closing water valve that doesn't shut off instantly but slowly drips to a stop. This "drip" wastes energy in the form of heat. The ultra-fast NPT technology in this module significantly shortens this tail, making the turn-off process quicker and more efficient. Crucially, its low temperature dependence means this efficiency is maintained even under heavy thermal loads.

Complementing the IGBTs are the CAL diodes. A standard diode turning off can abruptly stop conducting, causing a sharp voltage spike and high-frequency oscillations (ringing). This is a major source of Electromagnetic Interference (EMI). The CAL diodes are engineered for a "soft" recovery. They behave more like a valve closing smoothly, preventing the electrical equivalent of a water hammer. This softness drastically reduces EMI, simplifies the requirements for external filtering, and enhances the reliability of the entire power stage.

Frequently Asked Questions (FAQ)

What is the primary benefit of the "fast & soft" inverse CAL diodes?

Their soft recovery characteristic is key to reducing voltage overshoot and EMI during switching. This allows for cleaner operation at high frequencies and can reduce the need for complex and costly external snubber circuits.

How does the short tail current impact system design in a real-world application like an electronic welder?

In a high-frequency welder, a shorter tail current directly translates to lower turn-off switching losses (E_off). This reduction in wasted energy means less heat is generated, allowing for a smaller heatsink, which in turn leads to a more compact and cost-effective final product.

Is this module suitable for paralleling to achieve higher current output?

Yes, IGBT modules in the SEMITRANS 3 package are designed with low internal inductance and are suitable for paralleling. However, successful implementation requires careful attention to symmetrical busbar design and individual gate drive circuits to ensure proper current sharing. For details on this, refer to manufacturer guidelines on IGBT Paralleling .

What does the DBC (Direct Copper Bonding) technology used for the baseplate mean for reliability?

DBC technology provides excellent thermal conductivity and a coefficient of thermal expansion (CTE) that is well-matched to silicon. This reduces mechanical stress on the IGBT and diode chips during temperature cycles, significantly improving the module's long-term reliability and power cycling capability.

Given its high-frequency capabilities, what is a typical gate driver recommendation?

For optimal performance, a gate drive unit (GDU) capable of providing a gate-emitter voltage of +15V for turn-on and a negative voltage (e.g., -8V to -15V) for turn-off is recommended. The negative voltage ensures a robust off-state, especially in noisy environments common to high-frequency inverters.

An Engineer's Perspective

From a design standpoint, the SKM400GB125D is not just a high-current switch; it's a specialized tool for high-frequency power conversion. Its value lies in the synergy between its fast IGBT silicon and the optimized CAL freewheeling diodes. This combination directly addresses the core engineering challenges of minimizing switching losses and controlling EMI in applications like inductive heating and resonant inverters. The robust thermal design, based on DBC technology, provides the reliability needed for industrial environments, ensuring that the module's performance remains stable and predictable across its operational lifespan. This module represents a focused solution for designers aiming to push the boundaries of power density and efficiency.