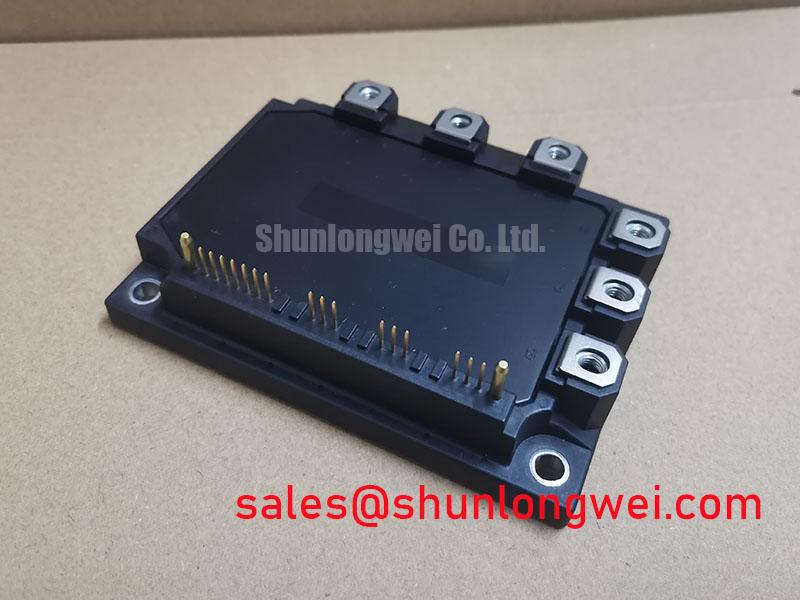

VUO86-16NO7 Technical & Application Review: A 1600V Three-Phase Rectifier Module

Engineered for High-Reliability Power Conversion

Content last revised on October 15, 2025.

The IXYS VUO86-16NO7 is a three-phase bridge rectifier module engineered for exceptional thermal performance and long-term reliability in demanding industrial power applications. Featuring key specifications of 1600V | 95A | 3000V~ Isolation, this module delivers two critical engineering benefits: superior heat dissipation and robust operational stability. It is designed to address the challenge of maintaining performance and longevity in thermally stressed environments, such as the input stages of motor drives and high-current power supplies. For industrial systems requiring a balance of high voltage blocking capability and efficient thermal management, the VUO86-16NO7 provides a robust and reliable rectification solution.

Key Parameter Overview

Decoding the Specs for Thermal Efficiency and Electrical Ruggedness

The technical specifications of the VUO86-16NO7 are foundational to its performance in industrial applications. The parameters below highlight its capacity for high-voltage, high-current rectification while emphasizing its robust thermal and mechanical design. Understanding these values is crucial for effective heatsink selection and system integration.

| Electrical Characteristics (at TVJ = 25°C, unless otherwise specified) | ||

|---|---|---|

| Parameter | Symbol | Value |

| Repetitive Peak Reverse Voltage | VRRM | 1600 V |

| Average Forward Current (TC = 100°C) | IdAVM | 86 A |

| Surge Forward Current (10 ms, 50 Hz, sine) | IFSM | 650 A |

| I²t Value for Fusing (10 ms, 50 Hz, sine) | I²t | 2100 A²s |

| Thermal and Mechanical Characteristics | ||

| Operating Junction Temperature Range | TVJ | -40°C to +150°C |

| Thermal Resistance, Junction to Case (per diode, DC) | RthJC | 0.4 K/W |

| Isolation Test Voltage (50/60 Hz, RMS, 1 min) | VISOL | 3000 V~ |

| Mounting Torque (M5) | Md | 2.25 - 2.75 Nm |

Download the VUO86-16NO7 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in Industrial Drives and Power Supplies

The VUO86-16NO7 is optimized for the input rectification stage of three-phase power conversion systems where reliability and thermal stability are non-negotiable. Its robust design provides significant value in applications such as Variable Frequency Drives (VFDs), industrial power supplies, and battery charging systems.

Consider the engineering challenge of designing an input rectifier for a 15 kW VFD operating in a factory with high ambient temperatures. The primary concern is preventing the rectifier diodes from overheating during sustained high-load conditions, which could lead to premature failure and costly system downtime. The VUO86-16NO7 directly addresses this through its low thermal resistance (RthJC) of 0.4 K/W per diode. This specification signifies highly efficient heat transfer from the silicon chip to the module's base plate. Think of Thermal Resistance as the narrowness of a pipe; a lower RthJC value is like a wider pipe, allowing heat to escape more easily. This allows the system designer to maintain lower, safer junction temperatures, thereby enhancing the drive's operational lifespan and reliability. While this model is well-suited for a wide range of applications, for systems with lower current demands but similar voltage requirements, the related VUB72-16NO1 may be a consideration.

Technical Deep Dive

The Reliability Advantage of the Direct Copper Bonded (DCB) Substrate

A critical, yet often overlooked, feature that defines the VUO86-16NO7's long-term reliability is its internal construction, specifically the use of a Direct Copper Bonded (DCB) aluminum oxide (Al2O3) ceramic base plate. This technology is a cornerstone of its superior thermal performance and mechanical robustness compared to modules using older, less advanced construction methods.

In a DCB substrate, a sheet of pure copper is bonded directly to the ceramic insulator without any intermediate solder or adhesive layer. This creates an integral, void-free bond with an extremely efficient thermal pathway. What is the primary benefit of a Direct Copper Bonded substrate? Enhanced thermal cycling capability and lower thermal stress. The DCB's coefficient of thermal expansion (CTE) is well-matched to that of the silicon chips, minimizing mechanical stress during the heating and cooling cycles inherent in power applications. This significantly reduces the risk of fatigue-related failures, such as solder joint cracking, which is a common failure mode in modules with traditional soldered base plates. This robust construction makes the VUO86-16NO7 particularly suitable for applications with frequent on/off cycles or fluctuating loads.

Frequently Asked Questions (FAQ)

What is the primary advantage of the 3000V~ isolation rating for the VUO86-16NO7?

The 3000V RMS isolation voltage provides a significant safety margin for systems connected to industrial three-phase lines (e.g., 400V, 480V). It ensures robust electrical separation between the high-voltage input and the module's mounting base (heatsink), which simplifies system-level safety compliance and enhances overall equipment and operator safety.

How does the VRRM of 1600V impact system design for industrial applications?

A Repetitive Peak Reverse Voltage (VRRM) of 1600V makes the module suitable for rectifying 400V and 480V AC lines, providing ample margin to withstand voltage transients and spikes commonly found on industrial power grids. This high voltage rating is a key factor in ensuring the rectifier's survival and reliability in electrically noisy environments without requiring additional, complex overvoltage protection circuits.

Is the VUO86-16NO7 suitable for parallel operation to achieve higher current output?

While the datasheet does not explicitly detail procedures for paralleling, the module's characteristics are generally amenable to it. For successful parallel operation, careful consideration must be given to ensuring balanced current sharing. This typically involves matching the forward voltage characteristics of the modules and ensuring symmetrical busbar and wiring layouts to equalize series resistance. A thorough design review is recommended for such configurations.

Engineering Support for Your Power System Design

Selecting the appropriate rectifier module is a critical step in ensuring the efficiency and reliability of your power conversion system. For assistance in evaluating the VUO86-16NO7 for your specific application or to explore a broader range of power semiconductor solutions, please contact our technical support team for detailed guidance.