Content last revised on January 26, 2026

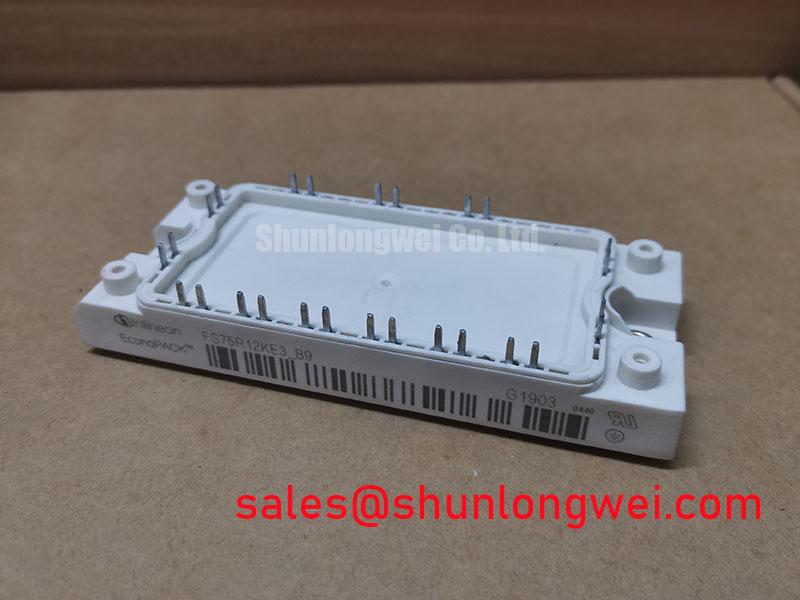

FS75R12KE3_B9: High-Efficiency 1200V IGBT Six-Pack Module for Demanding Drive Applications

Introduction: A Deep Dive into the FS75R12KE3_B9

The Infineon FS75R12KE3_B9 is a 1200V, 75A six-pack IGBT module engineered for high-reliability power conversion systems requiring a balance of efficiency and robust thermal performance. This module integrates TRENCHSTOP™ IGBT3 and Emitter Controlled 3 diode technology within the industry-standard EconoPACK™ 2 housing. Key Specifications: 1200V | 75A | VCE(sat) of 1.70V. Its primary advantages include low switching losses and excellent thermal conductivity. For engineers designing motor drives or UPS systems, this module directly addresses the challenge of minimizing heat dissipation while maintaining high switching frequencies. For motor control systems up to 25 kW, the FS75R12KE3_B9's thermal and electrical characteristics provide an optimized solution for achieving high power density.

Application Scenarios & Value

System-Level Benefits in Variable Frequency Drives and UPS

In the design of modern Variable Frequency Drive (VFD) systems, achieving high efficiency to meet standards like IEC 61800-3 is paramount. A primary engineering challenge lies in managing the trade-off between switching frequency and thermal losses. The FS75R12KE3_B9 directly confronts this issue with its low collector-emitter saturation voltage (VCE(sat)) of 1.70V (typical at 25°C). This low on-state voltage significantly reduces conduction losses, which is analogous to using a thicker gauge wire that offers less resistance to current flow. The result is less energy wasted as heat, allowing for smaller heatsink designs or higher ambient operating temperatures. This is particularly critical in space-constrained applications such as servo drives and uninterruptible power supplies (UPS), where power density is a key performance indicator. For systems requiring higher current handling capabilities, the related FS150R12KE3 provides a 150A alternative within a similar technology family.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the FS75R12KE3_B9 are tailored for robust and efficient operation in three-phase inverter applications. The parameters below highlight its capability to manage demanding electrical and thermal loads.

| Parameter | Value | Conditions |

|---|---|---|

| Collector-Emitter Voltage (V_CES) | 1200 V | T_vj = 25°C |

| Continuous Collector Current (I_C nom) | 75 A | T_C = 100°C |

| Collector-Emitter Saturation Voltage (V_CE sat) | 1.70 V | I_C = 75 A, T_vj = 25°C |

| Total Switching Energy (E_tot) | 12.5 mJ | I_C = 75 A, V_CE = 600V, T_vj = 125°C |

| Thermal Resistance, Junction-to-Case (R_thJC) | 0.24 K/W | per IGBT |

| Maximum Junction Temperature (T_vj max) | 150°C | |

| Housing | EconoPACK™ 2 |

Download the FS75R12KE3_B9 datasheet for detailed specifications and performance curves.

Technical Deep Dive

A Closer Look at TRENCHSTOP™ IGBT3 Technology for Optimized Performance

The core of the FS75R12KE3_B9's performance lies in its use of Infineon's TRENCHSTOP™ IGBT3 technology. This generation of IGBTs is specifically optimized for a low VCE(sat) and reduced switching losses, particularly in applications operating at switching frequencies up to 20 kHz. Unlike older planar IGBT technologies, the trench-gate structure creates a vertical current path that significantly increases the charge carrier density in the drift region during the on-state. This is like creating multiple parallel lanes on a highway instead of a single one, drastically reducing "traffic congestion" and thus lowering the voltage drop (VCE(sat)). The benefit for an engineer is twofold: lower conduction losses translate directly to higher inverter efficiency, and the balanced switching characteristics (E_on and E_off) help to control EMI generation, potentially simplifying the filtering stage in the overall system design.

Frequently Asked Questions (FAQ)

How does the VCE(sat) of 1.70V impact the thermal design of a power stage?

A lower VCE(sat) directly reduces the power lost as heat during conduction (P_cond = VCE(sat) * I_C). This reduction in heat generation means a smaller, less expensive heatsink may be used to maintain the same junction temperature, or the module can be operated at a higher output current for a given thermal solution, improving the overall power density of the inverter.

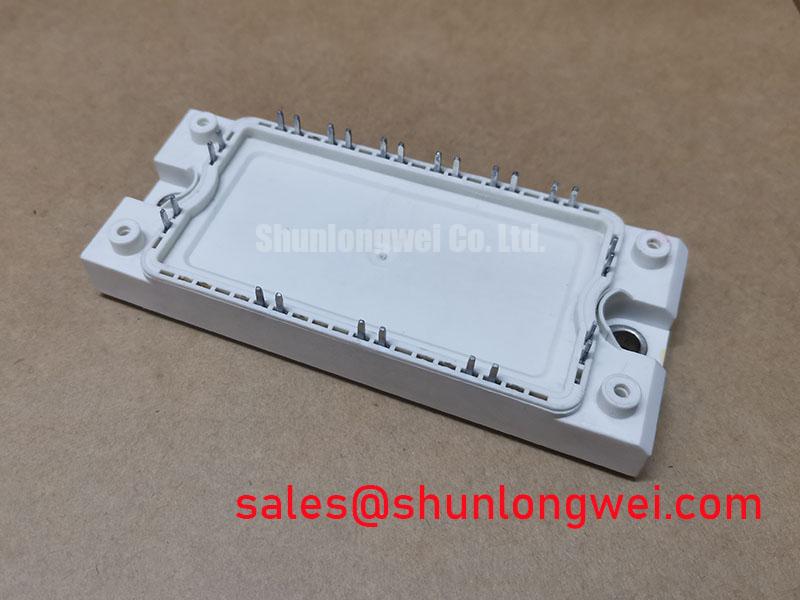

What is the primary advantage of the EconoPACK™ 2 housing for industrial applications?

The EconoPACK™ 2 housing provides a mechanically robust platform with industry-standard mounting footprints, simplifying assembly and integration. Its screw terminals ensure reliable, high-current connections, which is crucial for maintaining performance and safety in high-vibration environments typical of industrial motor drives and manufacturing equipment.