Content last revised on January 12, 2026

Mitsubishi RM600HD-34S | A High-Reliability 1700V IGBT Module for Demanding Power Conversion

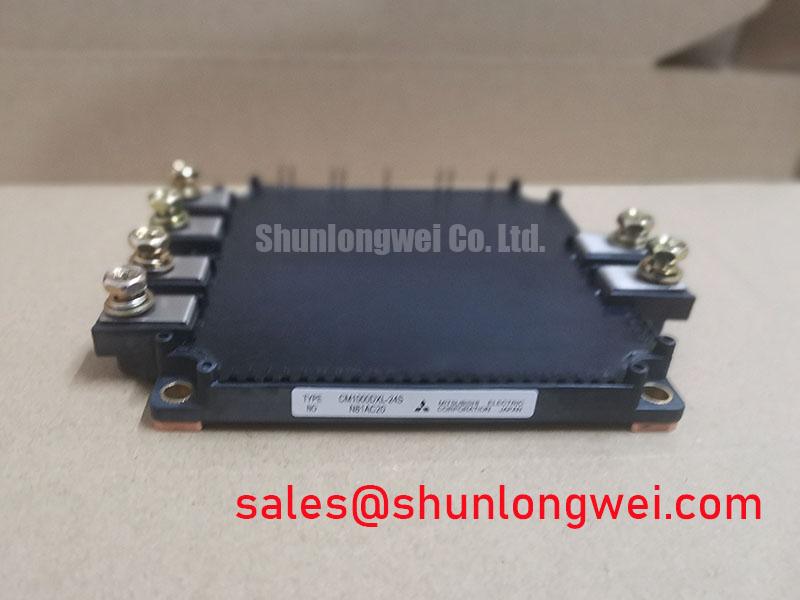

The Mitsubishi RM600HD-34S is a high-performance IGBT module engineered for the rigorous demands of high-power industrial applications. As a key component in the 1700V class, this half-bridge module provides a robust and efficient solution for power conversion systems where reliability is not just a feature, but a fundamental requirement. It combines Mitsubishi's advanced chip technology with a thermally optimized package to deliver consistent performance and extended operational life.

Product Highlights

- High Power Density: Rated for 1700V collector-emitter voltage (V_CES) and 600A continuous collector current (I_C), enabling use in systems up to the megawatt scale.

- Advanced Chip Technology: Utilizes Mitsubishi's proven CSTBT™ (Carrier Stored Trench Bipolar Transistor) technology, which achieves an exceptional balance between low conduction losses (V_CE(sat)) and switching performance.

- Superior Thermal Performance: Built on an industry-standard package with an AlSiC baseplate, ensuring excellent thermal conductivity and a low coefficient of thermal expansion (CTE) for enhanced power cycling capability.

- Robust Half-Bridge Configuration: The 2-in-1 (half-bridge) topology is ideal for simplifying the design of common inverter and chopper circuits.

Application Scenarios & Value Proposition

The RM600HD-34S is not a general-purpose component; it is specifically designed to excel in applications where electrical and thermal stresses are significant. Its design directly addresses common engineering challenges in these fields.

- Renewable Energy Inverters: In large-scale wind turbine and solar power converters, efficiency and uptime are paramount. The low V_CE(sat) of the RM600HD-34S minimizes conduction losses, directly translating to higher energy yield. Its exceptional thermal cycling endurance ensures long-term reliability in environments with fluctuating power generation.

- High-Power Motor Drives: For industrial motor drives in applications like mining, rolling mills, and marine propulsion, this module provides the raw power handling and ruggedness required. Its ability to withstand high surge currents and its stable thermal characteristics prevent premature failure under heavy load conditions.

- Industrial UPS (Uninterruptible Power Supply): Data centers, hospitals, and manufacturing plants rely on UPS systems for grid stability. The RM600HD-34S offers the reliability needed to ensure seamless power delivery during grid failures, backed by a robust Safe Operating Area (SOA) that can handle demanding load transitions.

Technical Deep Dive: The Engineering Inside

Two core aspects define the superior performance of the Mitsubishi RM600HD-34S: its silicon and its packaging. Understanding these reveals why it's a trusted choice for high-stress applications.

First is the implementation of Mitsubishi CSTBT™ technology. Unlike standard trench IGBTs, CSTBT™ incorporates a unique carrier-stored layer beneath the trench gate structure. This innovation significantly boosts conductivity modulation, allowing the device to achieve a remarkably low on-state voltage drop (V_CE(sat)) for its voltage class. For the design engineer, this means less power dissipated as heat, leading to a cooler-running system, reduced heatsink requirements, and ultimately, higher overall inverter efficiency.

Second is the focus on thermomechanical reliability. The module's construction pairs the silicon die with an AlN (Aluminum Nitride) insulating substrate and an AlSiC (Aluminum Silicon Carbide) baseplate. This material combination is critical. AlSiC's CTE is an excellent match for silicon, minimizing the mechanical stress on the die and solder joints during temperature swings (power cycles). This synergy results in a significantly longer service life compared to modules using traditional copper baseplates, a critical factor in reducing total cost of ownership.

Key Parameters Overview

The following table outlines the essential electrical and thermal characteristics. For comprehensive data, including detailed graphs and application notes, please refer to the official documentation.

| Parameter | Symbol | Value |

|---|---|---|

| Collector-Emitter Voltage | V_CES | 1700 V |

| Continuous Collector Current (@ T_c=80°C) | I_C | 600 A |

| Collector-Emitter Saturation Voltage (Typ. @ I_C=600A) | V_CE(sat) | 2.1 V |

| Gate-Emitter Threshold Voltage | V_GE(th) | 5.0 V - 7.0 V |

| Maximum Power Dissipation (@ T_c=25°C) | P_C | 4400 W |

| Maximum Junction Temperature | T_j(max) | 150 °C |

For detailed specifications, please Download the RM600HD-34S Series Datasheet.

Engineer's FAQ

What are the key considerations for the gate drive design for the RM600HD-34S?

Given its high power rating, a robust gate drive is essential. We recommend a dual-supply voltage, typically +15V for turn-on and -10V to -15V for turn-off. The negative gate voltage provides a strong buffer against dV/dt induced parasitic turn-on, a common failure mode in high-voltage bridge topologies. Ensure the gate driver can supply sufficient peak current (typically >10A) to quickly charge and discharge the gate capacitance, minimizing switching losses. For more insights, review these 5 practical tips for robust IGBT gate drive design.

Can this module be paralleled for higher current output?

Yes, the RM600HD-34S is suitable for paralleling. Its positive temperature coefficient of V_CE(sat) provides a degree of self-balancing, as a hotter module will naturally conduct slightly less current. However, successful paralleling requires careful attention to symmetrical busbar layout to equalize stray inductances and ensure uniform current sharing during switching transients. For critical designs or further assistance, please contact our technical team to discuss your application specifics.