Content last revised on January 27, 2026

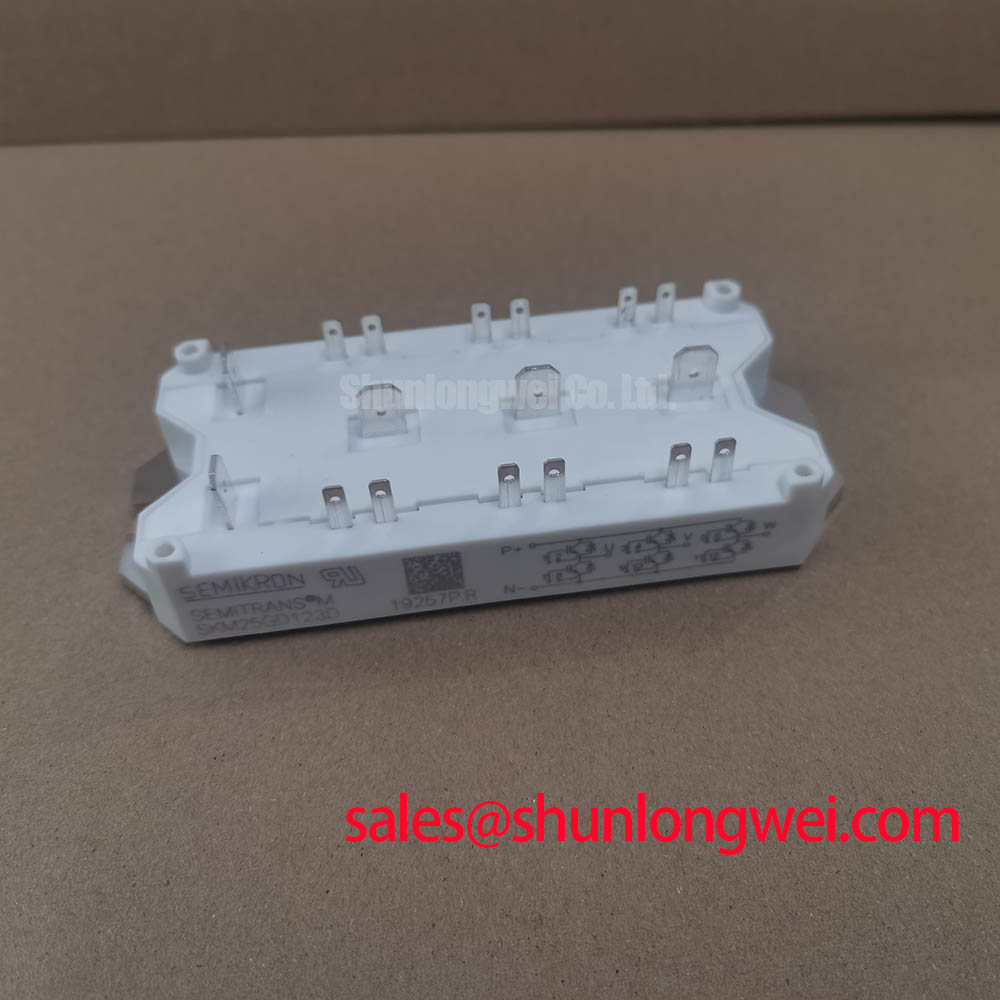

SEMIX302GB126V1 | 1200V 410A Half-Bridge IGBT Module

An Engineering Analysis of the SEMIKRON SEMIX302GB126V1 IGBT Module

The SEMIX302GB126V1 is a half-bridge IGBT module engineered for superior thermal stability and long-term reliability in demanding power conversion systems. Featuring core specifications of 1200V | 410A (Nominal IC) | 1.9V VCE(sat) (typ.), this module delivers two critical engineering benefits: simplified parallel operation and enhanced assembly reliability. It provides a direct solution for high-power system design by ensuring stable current sharing between parallel modules, which is essential to prevent thermal runaway. For systems demanding high reliability, its press-fit contacts eliminate solder fatigue, a common failure point in industrial environments. For high-power motor drives requiring robust parallel operation, this module's positive VCE(sat) temperature coefficient makes it a definitive choice.

Key Parameter Overview

Analyzing Electrical and Thermal Ratings for System Design

The technical specifications of the SEMIX302GB126V1 are optimized for robust performance in high-power applications. The following parameters are critical for design evaluation, thermal modeling, and ensuring operation within the device's safe operating area.

| Parameter | Symbol | Condition | Value | Unit |

|---|---|---|---|---|

| Absolute Maximum Ratings | ||||

| Collector-Emitter Voltage | VCES | 1200 | V | |

| DC Collector Current | IC | Tcase = 25 °C | 410 | A |

| DC Collector Current | IC | Tcase = 80 °C | 315 | A |

| Total Power Dissipation | Ptot | Tcase = 25 °C | 1785 | W |

| Gate-Emitter Voltage | VGES | ± 20 | V | |

| IGBT Characteristics (per switch) | ||||

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 300 A, Tj = 25 °C | 1.9 (typ.) / 2.35 (max.) | V |

| Collector-Emitter Saturation Voltage | VCE(sat) | IC = 300 A, Tj = 125 °C | 2.15 (typ.) | V |

| Turn-On Energy | Eon | IC = 300 A, Tj = 125 °C | 57 (typ.) | mJ |

| Turn-Off Energy | Eoff | IC = 300 A, Tj = 125 °C | 60 (typ.) | mJ |

| FWD Characteristics (per switch) | ||||

| Forward Voltage | VF | IF = 300 A, Tj = 25 °C | 1.85 (typ.) / 2.3 (max.) | V |

| Reverse Recovery Energy | Erec | IF = 300 A, Tj = 125 °C | 31 (typ.) | mJ |

| Thermal Characteristics | ||||

| Thermal Resistance, Junction to Case | Rth(j-c) | per IGBT | 0.07 | K/W |

| Operating Junction Temperature | Tj(op) | -40 to +150 | °C | |

Download the SEMIX302GB126V1 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Advantages in Industrial Drives and Renewable Energy Converters

The SEMIX302GB126V1 is engineered for applications where reliability and thermal performance are paramount. Its features provide tangible benefits in demanding industrial and renewable energy systems.

- Variable Frequency Drives (VFDs): In high-power Variable Frequency Drive (VFD) systems, paralleling modules to increase output current is a common design strategy. The primary challenge is ensuring balanced current sharing to prevent thermal runaway in one of the modules. The SEMIX302GB126V1's IGBTs feature a positive temperature coefficient for VCE(sat). This acts as a passive self-balancing mechanism; as one chip's temperature rises, its on-state resistance increases, naturally shunting current to the cooler, parallel device. This inherent characteristic simplifies the power stage design and significantly enhances system-level reliability.

- Solar and Wind Inverters: The efficiency and long-term reliability of renewable energy inverters are critical for return on investment. The module's use of CAL (Controlled Axial Lifetime) freewheeling diodes provides soft recovery characteristics. This reduces voltage overshoots and electromagnetic interference (EMI), which simplifies filter design and helps meet stringent grid-connectivity standards.

- Uninterruptible Power Supplies (UPS): For data centers and critical infrastructure, UPS systems must deliver uncompromising reliability. The module's press-fit auxiliary contacts and robust thermal design contribute to a longer operational lifetime, reducing the total cost of ownership.

For applications requiring even higher current handling within a similar package, the related SEMIX453GB12VS offers an increased current rating.

Frequently Asked Questions

Addressing Key Design Considerations for the SEMIX302GB126V1

How does the positive temperature coefficient of VCE(sat) benefit designs using parallel modules?

A positive temperature coefficient means that as the IGBT junction temperature increases, its on-state voltage drop (VCE(sat)) also increases. In a parallel configuration, if one module starts to carry more current and heat up, its rising VCE(sat) will naturally cause current to redistribute to the other, cooler modules. This self-regulating effect prevents thermal runaway and ensures stable, long-term operation without complex active balancing circuits, making it one of the most important factors when decoding IGBT datasheets for high-power designs.

What are the practical advantages of the solder-free press-fit auxiliary contacts?

Solder joints are a common point of failure in power modules subjected to frequent thermal cycling and mechanical vibration. The press-fit (spring) contacts for the gate driver board connection eliminate solder entirely. This creates a highly reliable, gas-tight connection that is resilient to thermo-mechanical stress, leading to a significant increase in the module's operational lifetime and simplifying the manufacturing assembly process.

Is the SEMIX302GB126V1 suitable for high-frequency switching applications?

The module utilizes SEMIKRON's Trench 3 IGBT technology, which offers a good balance between conduction losses (low VCE(sat)) and switching losses (Eon/Eoff). While not designed for the very high frequencies achievable with SiC, it performs efficiently in the typical frequency range for industrial motor drives and solar inverters (e.g., 2 kHz to 15 kHz). The low-inductance SEMiX package design also helps to minimize voltage overshoot during fast switching events.

Application Vignette

Case Study: Enhancing Reliability in a High-Power Variable Frequency Drive (VFD)

An engineering team is tasked with designing a 250 kW Servo Drive for a heavy-duty industrial conveyor system. A key challenge is managing the high start-up torque, which requires a transient current well beyond the capacity of a single IGBT module. The chosen architecture involves paralleling two half-bridge modules per phase to meet the peak current demand. The design must be exceptionally reliable to minimize costly downtime in the production line.

By selecting the SEMIX302GB126V1, the team directly addresses the critical challenge of current sharing. The module's positive VCE(sat) temperature coefficient ensures that under load, the two parallel modules inherently balance the current draw. This prevents a single module from shouldering a disproportionate load, which would otherwise lead to localized overheating and eventual failure. This feature simplifies the thermal design, as heat dissipation is more predictable and evenly distributed across the shared heatsink. The result is a robust power stage that operates reliably without requiring complex measurement and control circuits for current balancing, leading to a more streamlined and cost-effective final product.

Technical Deep Dive

A Closer Look at the Solder-Free Press-Fit Connection and CAL Diode Technology

Two key technologies within the SEMIX302GB126V1 contribute directly to its reliability and electrical performance: the press-fit auxiliary connection and the CAL freewheeling diode.

The solder-free press-fit design for the driver interface is a significant advancement for long-term reliability. In traditional soldered modules, the different coefficients of thermal expansion between the PCB and the module pins create mechanical stress on the solder joints during temperature cycling. Over thousands of cycles, this can lead to solder fatigue and connection failure. The press-fit system replaces this weak link with a compliant spring contact. This connection maintains a consistent, high-pressure electrical contact that is immune to the stresses of thermal cycling and mechanical vibration, a crucial advantage in harsh industrial environments.

The integrated CAL (Controlled Axial Lifetime) freewheeling diode is engineered for "soft" reverse recovery. When a diode turns off, its recovery can be abrupt, causing high-frequency ringing and voltage overshoot. A soft recovery diode is engineered to have a more controlled, less sudden turn-off. This is analogous to a vehicle's suspension smoothing out a harsh bump; it reduces electrical "shock" to the system. This softness lowers EMI emissions and dampens the voltage stress on the IGBT during turn-on, contributing to both improved electromagnetic compatibility and enhanced device longevity. This technology is a cornerstone of Semikron's approach to building robust power modules.

Request for Quotation

To inquire about the SEMIX302GB126V1 for your project, please contact our sales team. We provide engineering support to help you evaluate this component based on your specific application requirements. For systems that need a more integrated approach, the SKiiP 35NAB126V1 intelligent power module may also be a relevant consideration.