Content last revised on January 26, 2026

TDB6HK180N16RR_B11: High-Reliability 1600V Power Module for Demanding Industrial Drives

An Engineering Perspective on the TDB6HK180N16RR_B11

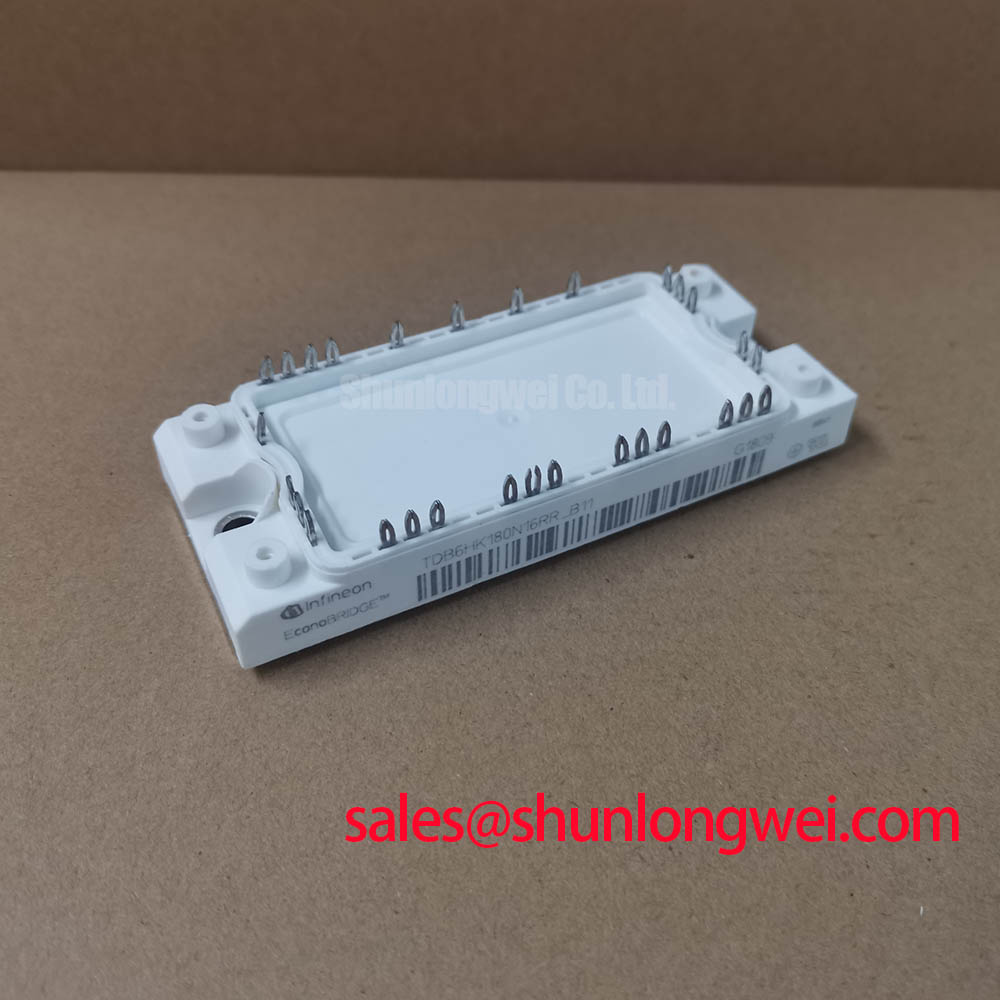

The Infineon TDB6HK180N16RR_B11 is an EconoBRIDGE™ module engineered for exceptional operational longevity in high-power industrial control systems. Its core value proposition is the delivery of consistent, long-term performance through a robust pressure contact design, eliminating a common failure point in conventional modules. With key specifications of 1600V | 180A, it provides substantial electrical headroom for demanding applications. Core engineering benefits include superior thermal cycling capability and simplified thermal management. This module directly addresses the need for durable power stages in applications like industrial motor drives and soft starters where operational uptime is paramount. For systems requiring robust power control with an emphasis on long-term reliability over tens of thousands of operating cycles, this module presents a compelling engineering choice.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The technical specifications of the TDB6HK180N16RR_B11 are foundational to its performance in demanding industrial environments. Each parameter is critical for system design, thermal modeling, and ensuring operational stability.

| Parameter | Value | Conditions |

|---|---|---|

| Thyristor/Diode Characteristics (Per Thyristor/Diode) | ||

| Repetitive Peak Reverse Voltage (VRRM) | 1600 V | Tvj = 25°C |

| DC Forward Current (IFAV) | 180 A | TC = 80°C, sin 180° |

| Surge Forward Current (IFSM) | 5100 A | Tvj = 25°C, t = 10 ms |

| IGBT Brake Chopper Characteristics | ||

| Collector-Emitter Voltage (VCES) | 1600 V | VGE = 0V, Tvj = 25°C |

| DC Collector Current (IC nom) | 75 A | - |

| Repetitive Peak Collector Current (ICRM) | 150 A | tp = 1 ms |

| Thermal and Mechanical Characteristics | ||

| Thermal Resistance, Junction to Case (RthJC) | 0.17 K/W | per Thyristor/Diode |

| Operating Junction Temperature (Tvj op) | -40 to 150 °C | - |

Download the TDB6HK180N16RR_B11 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

System-Level Benefits in AC Motor Control and Soft Starters

The TDB6HK180N16RR_B11 is specifically designed for the input rectifier stage of industrial power conversion systems. Its integrated topology, combining a half-controlled thyristor/diode bridge with an IGBT brake chopper, offers a compact solution for three-phase AC motor control applications, such as Variable Frequency Drives (VFDs) and soft starters. In a typical soft starter application, the challenge is managing high inrush currents during motor startup without causing line voltage sags or mechanical stress. The high surge current capability (IFSM) of 5100 A provides the necessary robustness to handle these transient events repeatedly. The integrated brake chopper is crucial for VFDs in applications with high inertia loads, such as conveyors or centrifuges, enabling efficient energy dissipation during deceleration and preventing DC bus overvoltage faults. This integration simplifies the overall design of the drive's power section, reducing component count and assembly complexity. For systems that do not require an integrated brake chopper, the related TDB6HK124N16RR provides a similar half-controlled bridge configuration.

Frequently Asked Questions

What is the primary advantage of the pressure contact technology used in the TDB6HK180N16RR_B11?

The key benefit of its pressure contact design is enhanced long-term reliability by eliminating solder fatigue. Unlike soldered modules, where thermal cycling can lead to joint cracking over time, this design maintains a consistent, high-pressure connection between the semiconductor die and the baseplate. This makes it exceptionally durable in applications with frequent temperature fluctuations, such as industrial drives with variable load profiles.

How does the 1600V rating benefit a system designer working with 400V or 480V AC lines?

A 1600V rating provides a significant safety margin for voltage transients on 400V or 480V three-phase systems. Line voltage spikes, caused by lightning, load switching, or other grid disturbances, can easily exceed the nominal peak voltage. The high VRRM ensures the device remains well within its Safe Operating Area (SOA), preventing catastrophic failure and improving the overall robustness and field reliability of the end equipment.

Technical Deep Dive

A Closer Look at the Pressure-Contact Design for Long-Term Reliability

The internal construction of the TDB6HK180N16RR_B11 is a critical differentiator. The use of Infineon's pressure contact technology fundamentally alters the module's resilience to thermomechanical stress. Think of it like a high-performance engine head gasket versus a simple adhesive. While a soldered connection is like an adhesive, forming a rigid bond, the pressure contact system acts like the gasket, using immense, consistent force to maintain electrical and thermal contact. During operation, as different materials inside the module expand and contract at different rates, a soldered joint is repeatedly stressed. Over thousands of cycles, this can lead to micro-cracks and eventual failure. The pressure contact design, however, accommodates this movement without degrading the connection, directly contributing to a longer operational lifetime and higher power cycling capability. This is a decisive factor for capital equipment like large industrial VFDs, where module replacement is a significant cost in terms of both parts and production downtime.