Content last revised on January 20, 2026

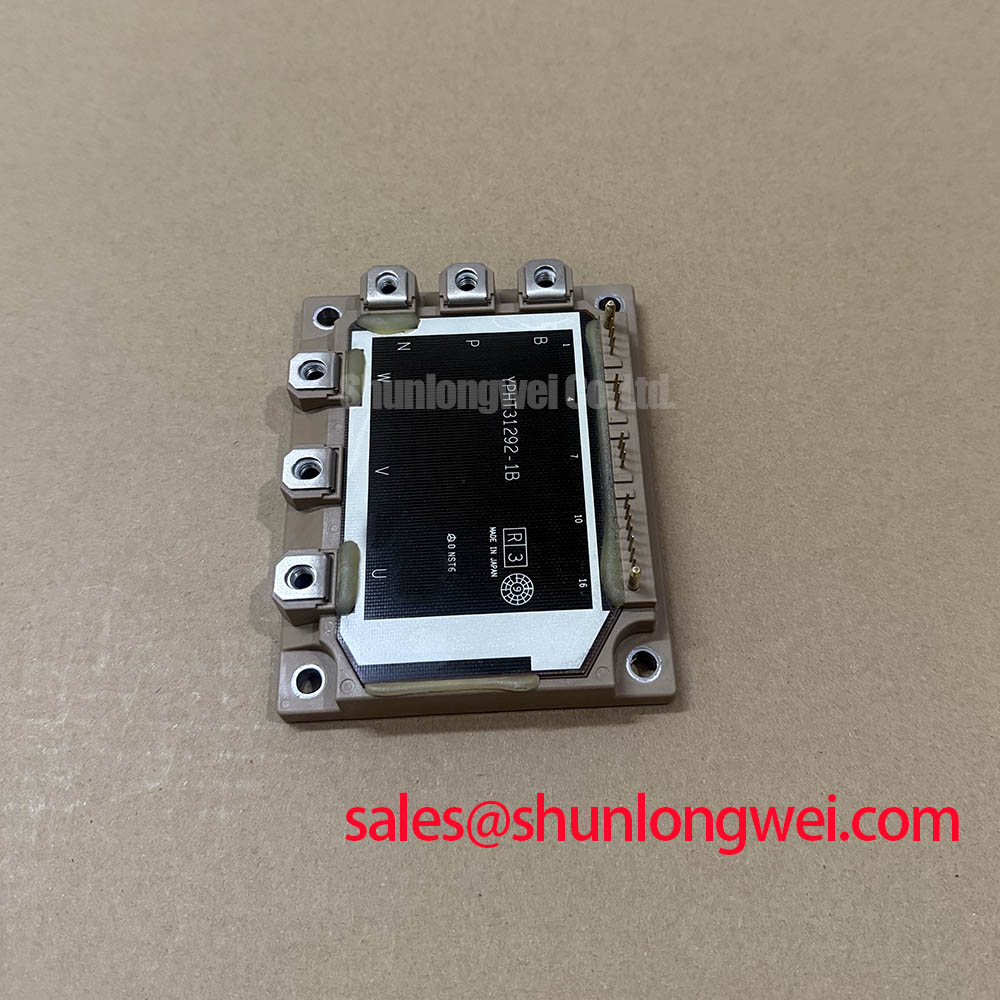

Fuji 6MBP160RUA060: 600V 160A PIM IGBT Module Analysis

Technical Introduction to the Integrated Power Core

The Fuji Electric 6MBP160RUA060 is a 7-in-1 IGBT Power Integrated Module (PIM) engineered to accelerate the design of compact motor drives by integrating a full power stage into a single component. With core specifications of 600V | 160A | VCE(sat) 2.7V max, this module provides a robust foundation for power conversion systems. Its key benefits include a dramatic reduction in component count and simplified thermal management. For engineers questioning how to reduce design complexity, this module consolidates the converter, inverter, and brake circuits, effectively streamlining the entire power electronics layout and assembly process.

Strategic Advantages in Modern Drive Manufacturing

In the competitive landscape of industrial automation, manufacturers of Variable Frequency Drives (VFDs) and servo systems face constant pressure to deliver smaller, more cost-effective, and highly reliable products. The adoption of integrated power modules like the 6MBP160RUA060 directly addresses these strategic objectives. By consolidating the three-phase diode rectifier, the three-phase IGBT inverter, and the dynamic brake chopper into one standard package, this PIM fundamentally changes the manufacturing calculus. It transforms a complex assembly of discrete components into a single, pre-validated subsystem. This integration not only reduces the physical footprint and bill of materials (BOM) but also minimizes assembly errors and accelerates time-to-market, allowing engineering resources to be focused on higher-level system features and software innovation.

Technical Inquiries for the 6MBP160RUA060

- How do I utilize the integrated NTC thermistor in the 6MBP160RUA060?

The built-in NTC thermistor provides a direct, real-time method for monitoring the module's substrate temperature. To use it, connect the thermistor pins (TH1, TH2) to a monitoring circuit, typically a voltage divider biased by a precision voltage source and read by a microcontroller's ADC. The resistance value, which corresponds to temperature, can be found in the datasheet's characteristic curves. This allows for precise implementation of over-temperature protection (OTP) and thermal foldback without needing an external sensor on the heatsink. - What is the main benefit of the 7-in-1 configuration (Converter-Inverter-Brake) in this PIM?

The primary benefit is system simplification. It replaces three separate power stages and their interconnections with a single component. This significantly reduces PCB design complexity, assembly time, and potential points of failure (e.g., solder joints, connectors). It also optimizes the internal layout for low stray inductance, a critical factor in mitigating voltage overshoots during high-frequency switching, a benefit explored further in resources covering IPM vs. discrete IGBT designs. - Can this module be used without the brake chopper circuit?

Yes, the brake chopper circuit can be left unused if the application does not require dynamic braking for deceleration. The inverter and converter sections function independently. In such cases, the brake chopper terminals (P-DB, B) would simply be left unconnected. This flexibility allows a single component to be specified across a product line with varying braking requirements, streamlining inventory management.

Data-Centric Evaluation for System Design

For engineering teams evaluating power modules, a direct comparison of key parameters is essential. The following table presents data points for the 6MBP160RUA060 alongside related models to facilitate a data-driven decision process. This information is intended to support your analysis based on specific system constraints, such as current requirements and thermal budgets.

| Part Number | Collector Current (Ic) | Collector-Emitter Voltage (Vces) | Max Saturation Voltage (Vce(sat)) | Package |

|---|---|---|---|---|

| 6MBP100RA060 | 100A | 600V | 2.7V | P629 |

| 6MBP160RUA060 | 160A | 600V | 2.7V | P629 |

| 6MBP200RA060 | 200A | 600V | 2.8V | P629 |

This comparative data highlights how modules within the same family offer scalable current handling in a consistent package footprint, allowing for platform-based design approaches.

Architectural Breakdown: The 7-in-1 Power Core

A granular analysis of the 6MBP160RUA060 reveals a highly efficient and logically structured power architecture. The module is built around Fuji Electric's U-series IGBTs, which are engineered for a favorable trade-off between low conduction losses and switching performance. What is the impact of its internal NTC thermistor? It provides an immediate and localized temperature reading, crucial for effective thermal protection.

Key Functional Blocks:

- Three-Phase Converter: A full-bridge rectifier stage designed to convert incoming AC line voltage into a stable DC bus.

- Three-Phase Inverter: Comprises six U-series IGBTs and six corresponding free-wheeling diodes (FWDs) in a standard three-phase bridge topology for driving AC motors.

- Brake Chopper: An additional IGBT and FWD allow for the dissipation of regenerative energy from a decelerating motor through an external braking resistor, preventing DC bus overvoltage.

- Integrated NTC Thermistor: This component acts as a dedicated thermal sensor. Its function is analogous to a built-in clinical thermometer, giving the control logic a precise, real-time reading of the module's operating temperature to prevent thermal runaway. A deeper understanding of such parameters is covered when learning to decode IGBT datasheets.

Deployment Scenarios: Maximizing Integration Benefits

The 6MBP160RUA060 is particularly well-suited for applications where space, assembly cost, and reliability are primary design drivers. Its integrated nature provides significant value in various industrial systems.

Primary Applications:

- Compact Variable Frequency Drives (VFDs): The all-in-one architecture enables the development of smaller motor drives for conveyors, pumps, and fans.

- Servo Drives: In robotics and CNC machinery, the module's high level of integration contributes to more compact and reliable servo amplifiers.

- General-Purpose Inverters: Suitable for power conversion units where a three-phase output and braking capability are required.

For motor drive applications up to approximately 75 kW requiring a compact, all-in-one power stage, the 6MBP160RUA060 offers an optimal balance of integration and performance based on its 160A rating and low thermal resistance.

From Blueprint to Production: A Deployment Snapshot

Consider a design team tasked with developing a new servo drive under a tight deadline. By selecting the 6MBP160RUA060, the team bypasses the complex and time-consuming process of selecting, testing, and laying out over a dozen discrete power semiconductors and their associated gate drive interfaces. Instead, they can focus on a single, well-characterized thermal interface and a simplified PCB. This consolidation accelerates the prototyping phase, reduces potential electromagnetic interference (EMI) loops through optimized internal connections, and streamlines the supply chain. The built-in NTC thermistor further simplifies the safety monitoring circuit, contributing to a faster path to regulatory compliance and market launch. For more information on the manufacturer, visit Fuji Electric.

Core Specifications at a Glance

The following table highlights the key performance metrics of the 6MBP160RUA060, sourced directly from the official datasheet. These values are fundamental for system-level simulation and design verification. What is the module's short-circuit withstand time? It is rated for 10 microseconds, providing robust protection against fault conditions.

| Parameter | Inverter Part (IGBT) | Brake Part (IGBT) | Converter Part (Diode) |

|---|---|---|---|

| Collector-Emitter Voltage (Vces / Vdrm) | 600V | 600V | 1600V |

| Collector Current (Ic / If) @ Tc=80°C | 160A | 80A | 160A |

| Max Collector Power Dissipation (Pc) | 570W | 350W | - |

| Max Junction Temperature (Tj) | 150°C | 150°C | 150°C |

Download the Datasheet for complete electrical and thermal characteristics.

Future-Proofing Designs with Integrated Power Architectures

Looking forward, the trend towards decentralization in automation and the increasing complexity of mechatronic systems will place even greater emphasis on modular and integrated solutions. Power Integrated Modules like the 6MBP160RUA060 represent a strategic asset in this evolution. By abstracting the complexity of the power stage into a reliable, plug-and-play block, they empower engineers to build more sophisticated, compact, and resilient systems. Adopting such integrated architectures is not merely a component choice; it is a strategic decision that aligns system design with the future demands of industrial efficiency and modularity, as detailed in discussions on Power Integrated Modules (PIM).