Content last revised on February 26, 2026

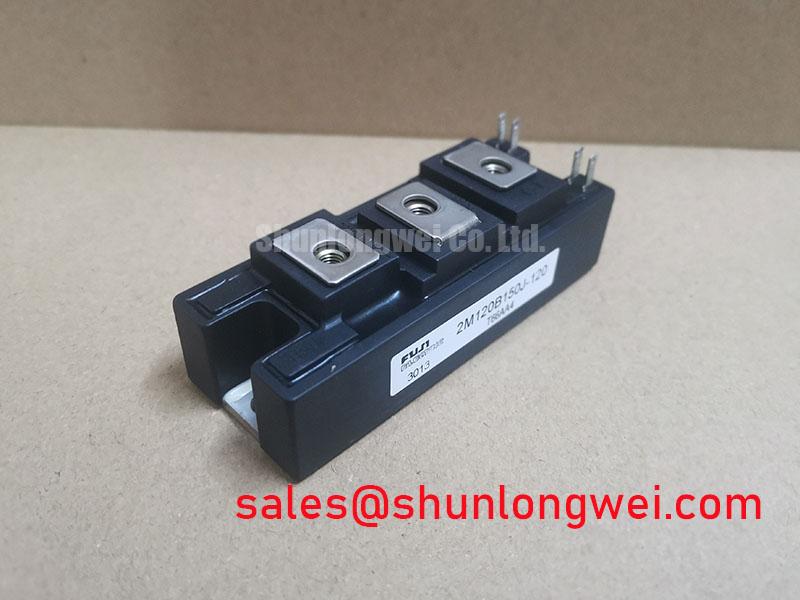

7MBR150VR120-50 Fuji Electric 1200V 150A PIM IGBT Module

The 7MBR150VR120-50, a cornerstone of the Fuji Electric V-Series Power Integrated Module (PIM) family, delivers a robust 1200V / 150A solution for high-density industrial power systems. By integrating a three-phase converter, a brake chopper, and a six-pack inverter along with a built-in thermistor into a single package, it significantly reduces parasitic inductance and streamlines the engineering of Variable Frequency Drives (VFD) and Servo Drive architectures. For 400V industrial systems prioritizing high thermal margin and integrated protection, this 1200V module stands as a technically sound choice for reliable power conversion. What is the primary benefit of its integrated thermistor? It provides real-time junction temperature monitoring for proactive over-temperature protection.

Key Parameter Overview

Decoding Technical Specifications for Enhanced System Reliability

The following technical data provides the baseline for engineering evaluation. The 7MBR150VR120-50 utilizes advanced Trench-Gate technology to achieve a typical VCE(sat) of 1.70V, directly translating to lower conduction losses during high-current operation.

| Functional Section | Parameter Description | Value / Unit |

|---|---|---|

| Inverter Section | Collector-Emitter Voltage (VCES) | 1200V |

| Inverter Section | Continuous Collector Current (IC) | 150A |

| Inverter Section | Collector Power Dissipation (PC) | 690W |

| Brake Section | Collector Current (IC) | 75A |

| Converter Section | Repetitive Peak Reverse Voltage (VRRM) | 1600V |

| Module Package | Max Junction Temperature (Tj) | +175°C |

Download the 7MBR150VR120-50 datasheet for detailed characteristic curves and safe operating area (SOA) specifications.

Application Scenarios & Value

Achieving System-Level Benefits in Industrial Motion Control

The 7MBR150VR120-50 is designed to address the specific challenges of 400V class industrial drives. In a typical variable frequency drive application, the 1200V rating provides a necessary safety buffer against regenerative voltage spikes, while the 150A current handling capacity supports mid-range motor loads. Engineers can leverage the integrated NTC thermistor to optimize Thermal Management, ensuring the system operates within its Safe Operating Area even under heavy cyclical loads.

For designers scaling their power stages, it is important to note that while this module provides 150A, systems requiring lighter current handling for compact drives may find the 7MBR75VR120-50 more appropriate for their footprint requirements. Conversely, if your design demands the latest N-series improvements, the 7MBR150VN120-50 offers an alternative architectural choice within the same current class. These modules are frequently utilized in UPS (Uninterruptible Power Supply) stages and comply with IEC 61800-3 EMC requirements when paired with appropriate filtering.

Technical & Design Deep Dive

Analyzing V-Series Chip Technology and Low-Loss Characteristics

The core efficiency of the 7MBR150VR120-50 stems from the field-stop trench technology employed in the V-Series chips. This structure effectively lowers the saturation voltage (VCE(sat)), which acts as the "electrical friction" within the module. To visualize this, consider VCE(sat) as the diameter of a pressure valve; a lower VCE(sat) is akin to a wider valve that allows fluid (current) to flow with minimal resistance, thereby reducing heat generation at the silicon level.

Furthermore, the Thermal Resistance (Rth) of the copper base plate is optimized to act as an efficient "thermal bridge," quickly moving heat from the semiconductor junction to the external heatsink. This efficiency is critical for long-term reliability in environments where ambient temperatures are high. Understanding why Rth matters is essential for engineers calculating the total cooling requirements of their inverter cabinets.

Industry Insights & Strategic Advantage

Supporting Efficiency Standards in the Era of Industry 4.0

As industrial regulations shift toward stricter energy efficiency targets and the adoption of Green Energy grows, the role of highly integrated IGBT Modules becomes paramount. The 7MBR150VR120-50 supports these trends by enabling more compact and efficient power conversion stages. Its multi-function integration aligns with the move toward modular manufacturing, where reducing component count is a direct path to lower Total Cost of Ownership (TCO) and improved assembly yield.

By utilizing integrated modules, OEMs can achieve better electromagnetic compatibility (EMC) more easily than with discrete components, a vital factor for global market compliance. For a broader perspective on how these components fit into the modern power grid, engineers may find our guide on the backbone of high-efficiency systems particularly useful for strategic planning.

Frequently Asked Questions

How does the built-in NTC thermistor improve system safety in the 7MBR150VR120-50?

The integrated NTC thermistor allows the controller to sense the baseplate temperature directly beneath the IGBT chips. This enables the system to implement fast derating or shutdown protocols if cooling fails, preventing catastrophic failure of the 150A inverter stage.

What are the primary design considerations for the converter section rating of 1600V?

The 1600V VRRM rating for the converter diodes is intentionally higher than the 1200V IGBT rating to handle the significant transient overvoltages often found on raw industrial AC mains, providing superior ruggedness against line surges.

Can this module be used in high-frequency switching applications above 20kHz?

While the V-Series is optimized for a balance between switching speed and conduction loss, switching frequencies above 20kHz require careful analysis of Switching Loss (Eon/Eoff). For high-frequency designs, refer to our analysis on IGBT selection beyond VCE(sat) to ensure thermal stability.

For procurement professionals and engineers looking to optimize their next-generation motor drives, the 7MBR150VR120-50 offers a proven, highly integrated platform that balances performance with thermal reliability. To discuss technical specifications or request a quote for your production requirements, please contact our technical sales team for data-driven support.