Content last revised on January 22, 2026

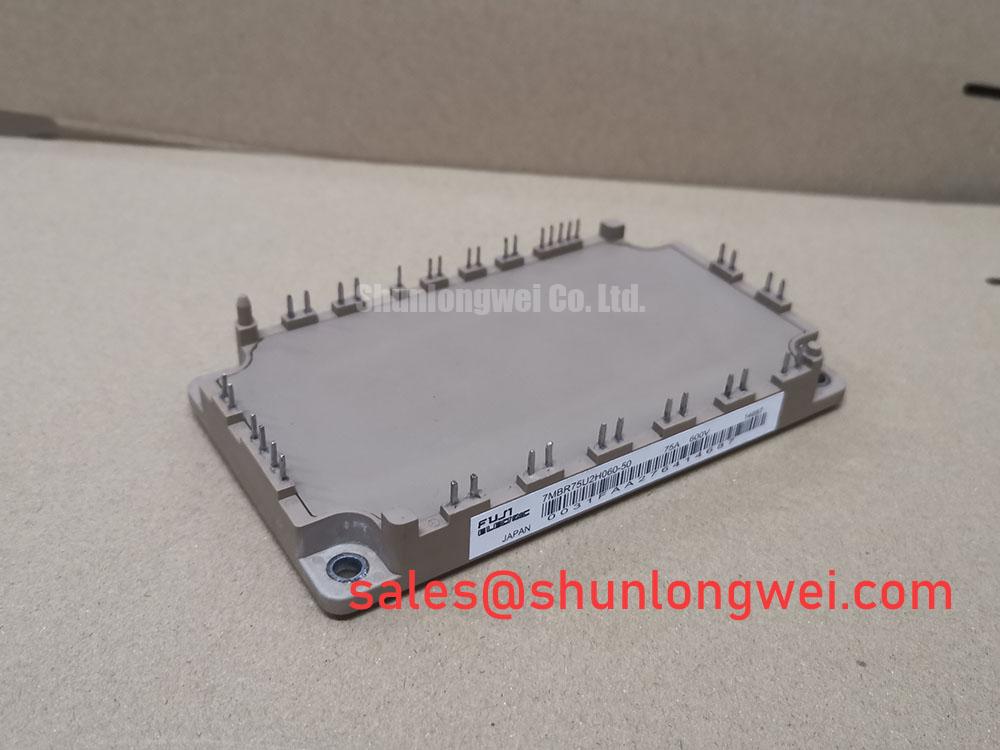

7MBR75U2H060-50: Fuji 600V/75A 7-in-1 V-Series IGBT Module

A 600V/75A 7-in-1 IGBT module engineered to accelerate development and reduce system complexity in compact motor drive applications.

The Fuji Electric 7MBR75U2H060-50 is a highly integrated power module from the 6th generation V-Series, designed to provide a complete power stage solution in a single compact package. Its core specifications are 600V / 75A for the inverter and brake chopper sections. Key benefits include a drastically reduced component count and simplified thermal management. This module directly addresses the engineering challenge of building compact, reliable variable frequency drives by consolidating the converter, inverter, and braking circuits, which minimizes PCB complexity and assembly time. What is the main benefit of the 7-in-1 topology? It significantly reduces component count and simplifies PCB layout.

Application Scenarios & Value

Streamlining Motor Drive Design Across Industries

The 7MBR75U2H060-50 is purpose-built to simplify the design and manufacturing of low-to-medium power motor control systems. Its high level of integration makes it an excellent fit for applications where space, assembly cost, and time-to-market are critical design constraints. The module's architecture combines a three-phase diode bridge converter, a brake chopper for managing regenerative energy, and a full three-phase inverter, creating a near-complete power core for AC motor drives.

- Compact Variable Frequency Drives (VFDs): The module's all-in-one nature allows for the creation of smaller, more power-dense VFDs for industrial pumps, fans, and conveyor systems.

- Servo Drives for Automation: In robotics and CNC machinery, the module's integrated structure contributes to smaller, more reliable servo drives, enabling precise motion control. For a deeper understanding of this application, explore the role of IGBTs in robotic servo drives.

- HVAC Systems: The module provides a robust power solution for compressor and air handler motors, where efficiency and long-term reliability are paramount.

- General-Purpose Inverters: Its versatile 7-in-1 configuration serves as a foundational building block for a wide range of general-purpose power conversion systems.

For compact drives under 30kW requiring a complete power stage with minimal design overhead, the 7MBR75U2H060-50's integrated 7-in-1 structure presents a clear advantage over multi-component designs.

Success Stories / Deployment Snippets

Deployment Focus: Enhancing Reliability in Automated Systems

While specific deployment details are confidential, components with the architecture of the 7MBR75U2H060-50 are frequently specified in automated material handling systems. In a typical scenario, a fleet of conveyor belts and sorting machines runs continuously. Using a discrete solution with separate rectifier, brake, and inverter components introduces numerous points of potential failure from soldering and interconnects. By migrating to an integrated 7-in-1 module like this one, engineering teams have reported a marked decrease in assembly errors and field failures. The primary value is derived from the reduction of inter-component wiring and the consolidation of thermal management onto a single, optimized heatsink interface, simplifying the entire mechanical and electrical assembly process.

Intra-Series Comparison & Positioning

Positioning the 7MBR75U2H060-50 in Fuji Electric's V-Series

The Fuji Electric V-Series comprises a broad portfolio of IGBT modules. The 7MBR75U2H060-50 is specifically positioned as a comprehensive solution for 200-240V AC line-powered systems. Its 600V blocking voltage provides the necessary design margin for these applications, while its 75A current rating supports motors typically in the 15 kW to 30 kW range, depending on operating conditions and overload requirements. For systems operating on higher voltage lines (e.g., 400-480V AC), designers would typically evaluate modules with a higher blocking voltage. For instance, the related 7MBR50VP120-50 offers a 1200V rating, suitable for those higher-voltage industrial environments, albeit with a lower current handling of 50A.

Technical Deep Dive

Anatomy of a Highly Integrated Power Stage

The core design philosophy of the 7MBR75U2H060-50 centers on maximizing functional density to simplify the end-system design. This is achieved by co-packaging seven distinct semiconductor devices into a single, thermally efficient module. The integration goes beyond just placing chips in a box; it involves optimizing the internal layout to minimize stray inductance and ensure balanced current sharing, factors that are challenging to control in a discrete layout. How is over-temperature protection implemented? Via a built-in NTC thermistor for direct temperature sensing. This integrated sensor provides a direct, real-time feedback path to the system's microcontroller, enabling robust over-temperature shutdown mechanisms without the cost and complexity of mounting an external sensor. This is a crucial feature for building reliable power systems, a concept further explored in the guide to IGBTs as the backbone of high-efficiency systems.

Industry Insights & Strategic Advantage

The Strategic Value of Integrated Power Modules in Modern Automation

The industrial automation landscape increasingly demands faster development cycles and higher field reliability. The move towards highly integrated power modules like the 7MBR75U2H060-50 is a direct response to this trend. By using a pre-packaged, pre-validated power stage, design teams can shift their focus from the complexities of power semiconductor layout and thermal interfacing to higher-level system software and control algorithms. This modular approach not only de-risks the hardware design process but also streamlines the supply chain by consolidating multiple part numbers into a single component. This strategic shift is a cornerstone of modern power electronic design, leveraging the advanced Fuji Electric V-Series IGBT technology to create more competitive and robust end products.

Key Parameter Overview

Engineering Specifications for System Evaluation

The following parameters are essential for evaluating the 7MBR75U2H060-50 for a specific motor drive or power conversion application. For a complete list of specifications and performance graphs, it is essential to consult the official datasheet.

| Parameter | Value | Notes |

|---|---|---|

| Collector-Emitter Voltage (Vces) | 600V | Provides necessary margin for 200-240V AC line applications. |

| Inverter Collector Current (Ic) | 75A (at Tc=80°C) | Defines the continuous current handling capability of the inverter stage. |

| Collector-Emitter Saturation Voltage (Vce(sat)) | 2.10V (Typ.) / 2.70V (Max.) | A key determinant of conduction losses and overall inverter efficiency. |

| Total Power Dissipation (Pc) | 390W (Inverter Part) | Represents the module's capacity to dissipate heat, critical for thermal design. |

| Operating Junction Temperature (Tj) | +150°C (Max.) | The maximum allowable temperature for the semiconductor junctions. |

| Isolation Voltage (Viso) | 2500V (AC for 1 minute) | Ensures safety and electrical isolation between the power circuit and the mounting baseplate. |

Frequently Asked Questions (FAQ)

What is the primary benefit of the integrated NTC thermistor in the 7MBR75U2H060-50?

The integrated NTC thermistor provides a direct, real-time measurement of the module's internal temperature. This simplifies the design of over-temperature protection circuits by eliminating the need for an external temperature sensor on the heatsink, which would introduce thermal lag and reduce measurement accuracy. This direct feedback allows the system controller to react more quickly to thermal overload conditions, enhancing system reliability.

How does this 7-in-1 module simplify the design of a low-power VFD?

It drastically reduces system complexity. Instead of sourcing, qualifying, and laying out a separate three-phase rectifier, a brake chopper transistor and diode, and a six-pack inverter module, an engineer can use this single component. This reduces PCB footprint, minimizes trace routing complexity (especially for high-current paths), simplifies the bill of materials (BOM), and shortens the overall assembly process, leading to lower manufacturing costs and a faster time-to-market.

Can the converter and inverter sections of this module be used independently?

While electrically possible, the module is designed and thermally optimized for use as a complete motor drive power stage. The internal layout and terminal arrangement are configured for this specific topology. Using the sections for entirely separate functions would require careful consideration of the electrical and thermal interactions, and it may not be the most efficient use of the component compared to dedicated modules for those separate tasks. A thorough review of the datasheet is crucial before attempting such a configuration. For more guidance on interpreting technical documents, see our guide on decoding IGBT datasheets.

As power electronics design continues to evolve, integrated modules like the 7MBR75U2H060-50 represent a strategic path toward developing more compact, cost-effective, and reliable systems. By leveraging such pre-engineered solutions, design teams can accelerate innovation and focus on delivering advanced features in their end applications, from industrial automation to energy-efficient commercial products.