Content last revised on January 31, 2026

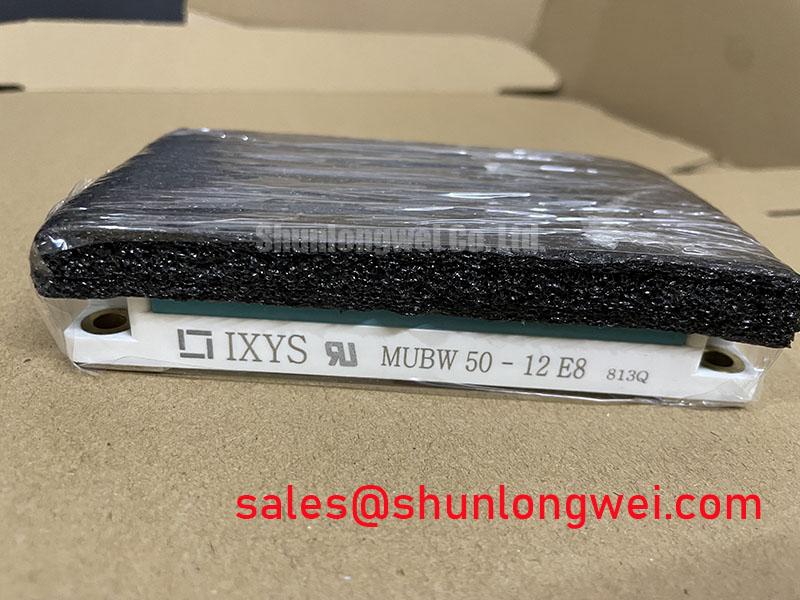

MUBW50-12E8 IXYS 1200V 55A Converter Brake Stepper Module

The MUBW50-12E8, an IXYS proprietary Converter-Brake-Stepper (CBS) module, offers an integrated power solution for compact motor drive designs, featuring a three-phase input rectifier, a six-pack inverter, and a dedicated brake chopper in a single E2-Pack housing. This high-density IGBT Module provides a 1200V collector-emitter voltage and a 55A continuous collector current at 80°C, significantly reducing system footprint and assembly complexity. For compact 400V industrial drives requiring integrated braking control, the MUBW50-12E8 is the optimal choice to balance power density and thermal performance.

Top Specs: 1200V | 55A (Tc=80°C) | Vce(sat) 2.2V

- Integrated Topology: Combines rectifier, inverter, and brake for simplified layout.

- High Thermal Stability: Direct Copper Bonding (DCB) substrate for optimized heat transfer.

What is the primary benefit of the CBS topology in the MUBW50-12E8? It consolidates ten power semiconductors into one package, eliminating the parasitic inductance and reliability risks associated with discrete component interconnects.

Key Parameter Overview

Decoding the Specs for Enhanced Thermal Reliability

The MUBW50-12E8 is engineered with a NPT (Non-Punch Through) IGBT structure, ensuring a positive temperature coefficient for Vce(sat), which is critical for engineers considering current sharing or parallel operation. The module provides a high Short-Circuit Withstand Time of 10 µs, offering a robust safety margin for Variable Frequency Drive (VFD) protection circuits. Below are the specific technical ratings segmented by functional blocks:

| Functional Block | Parameter Symbol | Typical Value | Conditions |

|---|---|---|---|

| Input Rectifier | Vrrm | 1600V | Max repetitive reverse voltage |

| Input Rectifier | Ifav | 65A | Tc = 80°C, sine 180° |

| Inverter IGBT | Vces | 1200V | Tvj = 25°C to 150°C |

| Inverter IGBT | Ic80 | 55A | Continuous current at Tc = 80°C |

| Inverter IGBT | Vce(sat) | 2.2V | Ic = 50A; Tvj = 25°C |

| Brake Chopper | Ic80 | 35A | Dedicated braking IGBT current |

| Module Package | Visol | 2500V~ | RMS isolation voltage (1 min) |

Download the MUBW50-12E8 datasheet for detailed specifications and performance curves.

Application Scenarios & Value

Achieving System-Level Benefits in High-Frequency Power Conversion

In the field of industrial automation, engineers often face the challenge of shrinking cabinet sizes while maintaining high current handling capabilities. The MUBW50-12E8 addresses this by utilizing an E2-Pack that integrates the entire power stage. In a typical Servo Drive application, the integrated brake chopper allows the system to dissipate regenerative energy during rapid motor deceleration without requiring external power transistors. This integration reduces the PCB trace count and simplifies the Gate Drive layout, lowering the risk of EMI-related failures.

Consider a heavy industrial conveyor system: the 1600V rating of the input rectifier bridge provides excellent immunity against line voltage transients often found in unstable power grids. By consolidating these functions, the MUBW50-12E8 minimizes the bill of materials (BOM). For systems requiring similar integration but slightly different power levels, the FP50R12KT4 provides an alternative configuration within the same power class. Understanding how these modules are constructed is essential for optimizing long-term reliability in IEC 61800-3 compliant designs.

Industry Insights & Strategic Advantage

The Strategic Shift Toward Power Integrated Modules (PIM)

The power electronics industry is moving rapidly toward "Power Integrated Modules" (PIM) as a standard for mid-range industrial drives. The MUBW50-12E8 represents this strategic alignment, focusing on "Total Cost of Ownership" (TCO) rather than just component price. By moving away from discrete components, manufacturers can achieve a 30% reduction in assembly time and a significant decrease in thermal interface management issues. This module acts like a pre-assembled power engine; you are not just buying a switch, but a verified power topology.

In the context of the global push for energy efficiency, the low Vce(sat) of 2.2V in the MUBW50-12E8 helps converters meet strict efficiency regulations by minimizing conduction losses. As designs move toward more intelligent monitoring, the module's E2-Pack footprint allows for easy integration of temperature sensors (NTC), providing real-time data for predictive maintenance. This shift is explored deeply in our analysis of IPM vs. Discrete IGBTs, where integration is cited as the primary driver for MTBF (Mean Time Between Failure) improvements in harsh environments.

Frequently Asked Questions

How does the Rth(jc) of the MUBW50-12E8 influence the selection of a heatsink?

With a thermal resistance (junction-to-case) of 0.32 K/W for the inverter IGBTs, the MUBW50-12E8 efficiently transfers heat to the baseplate. This low value allows for a smaller heatsink or higher ambient operating temperatures without exceeding the 150°C junction temperature limit, directly increasing the power density of the final Variable Frequency Drive (VFD).

Why is the 1600V rectifier rating significant for a 1200V IGBT module?

The 1600V Vrrm rating for the input bridge provides a critical safety buffer against voltage surges from the AC line. While the inverter section operates on a DC link derived from 400-480V AC, the input stage is exposed to raw grid transients. This "over-specification" of the rectifier is a deliberate engineering choice to prevent catastrophic module failure during grid disturbances.

What is the benefit of the NPT structure used in the MUBW50-12E8?

The NPT (Non-Punch Through) technology in the MUBW50-12E8 provides a square Reverse Bias Safe Operating Area (RBSOA) and a high level of ruggedness against overcurrent. Crucially, its positive temperature coefficient ensures that if one module gets hotter, its resistance increases, naturally discouraging thermal runaway and making it easier to manage in high-stress industrial cycles.

For engineering teams prioritizing volume reduction and high-speed assembly, the MUBW50-12E8 offers a field-proven architecture. Technical teams should evaluate the thermal performance of the E2-Pack early in the design phase to maximize the module's 55A current capability. To further understand the nuances of power selection, explore our guide on IGBT vs. MOSFET technologies for industrial applications.