Content last revised on January 22, 2026

SKIIP23NAB126V1: 1200V IPM for Simplified Motor Drive Design

Introduction to the SKIIP23NAB126V1 Intelligent Power Module

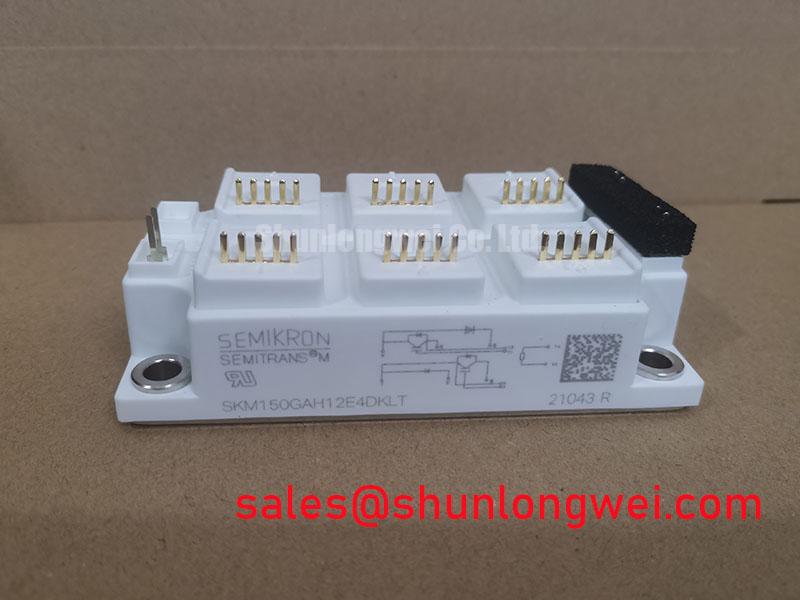

The Semikron SKIIP23NAB126V1 is an intelligent power module (IPM) engineered to accelerate system design by integrating a complete three-phase drive stage into a single, compact housing. This highly integrated solution drastically reduces complexity for engineers developing compact and efficient motor drives. Its all-in-one topology streamlines the design process by minimizing the need for external components, directly addressing the challenge of creating smaller yet more powerful drive systems. What is the key advantage of its construction? The solder-free pressure contact technology ensures a simplified, reliable assembly process and superior thermal performance.

- Core Specifications: 1200V (Inverter & Brake Chopper) | 75A (Inverter Nominal Current) | Integrated Rectifier, Brake Chopper & Inverter

- Key Benefits: Simplified assembly and mounting; significant reduction in system footprint.

Technical Deep Dive

An Architecture for System Simplification

The SKIIP23NAB126V1's design philosophy centers on maximizing integration to simplify the end application. The module combines a three-phase bridge rectifier, a brake chopper featuring a fast Trench IGBT, and a three-phase bridge inverter into one housing. This level of integration removes the need for multiple discrete components and the complex interconnects between them, shrinking the required PCB area and reducing assembly time. All power stages are built upon a single Direct Copper Bonded (DCB) substrate, creating a unified thermal interface that simplifies heatsink selection and mechanical design.

A defining feature of this module is Semikron's pressure contact technology for the main power terminals. This innovative approach eliminates the need for soldering, which is often a time-consuming process and a potential long-term failure point due to thermal cycling fatigue. Instead, reliable electrical connections are made through precisely controlled pressure, leading to faster, more consistent manufacturing and easier field serviceability. For more on how packaging impacts long-term performance, explore this guide on how IGBT packaging dictates thermal performance and reliability.

Application Scenarios & Value

Where Integrated Design Delivers Maximum Impact

The SKIIP23NAB126V1 is tailored for applications where power density, reliability, and speed of assembly are critical engineering goals. Its comprehensive feature set makes it an excellent fit for:

- Variable Frequency Drives (VFDs): The all-in-one nature simplifies the power core of compact VFDs used in industrial automation, pumps, fans, and conveyor systems. The integrated brake chopper is particularly valuable for applications requiring controlled deceleration.

- Servo Drives: In robotics and CNC machinery, the module's small footprint and integrated protections support the design of high-density, multi-axis servo drive systems.

- General-Purpose Inverters: For systems with a typical motor power of around 7.5 kW, this IPM provides a complete, pre-validated power stage that significantly shortens the development cycle.

For motor drive applications up to 16 kVA requiring a compact footprint and rapid assembly, the SKIIP23NAB126V1's integrated topology offers a clear total cost of ownership advantage over discrete solutions.

Success Stories / Deployment Snippets

Field-Proven Integration Concepts

While specific deployment details are proprietary, the engineering value of the SKiiP® platform is evident in common industrial scenarios. For instance, in upgrading a decentralized conveyor belt system, an engineering team could leverage the SKIIP23NAB126V1 to replace a bulky power stage built from discrete rectifiers, choppers, and IGBT modules. This substitution can lead to a significant reduction in the control cabinet volume, allowing for more flexible placement of the drive closer to the motor and reducing cabling costs and complexity.

Industry Insights & Strategic Advantage

Meeting the Demands of Modern Industrial Automation

The move towards Industry 4.0 and smarter, more compact machinery places immense pressure on designers to increase power density without sacrificing reliability. The SKIIP23NAB126V1 directly supports this trend. By integrating the entire power conversion and control stage, it acts as a key enabler for building smaller, more modular, and more reliable automation systems. This design approach not only enhances the performance of the final product but also streamlines the supply chain and manufacturing floor by reducing the number of components to be sourced, stocked, and assembled. In a similar vein, the SKiiP35NAB12T4V1 offers a higher current option within the same integrated paradigm for more demanding applications.

Key Parameter Overview

Critical Specifications for Integrated System Performance

Understanding the specifications of the SKIIP23NAB126V1 is crucial for successful system integration. The following table highlights key parameters and their direct engineering implications, based on the official datasheet. For a comprehensive list of specifications, please Download the Datasheet.

| Parameter | Value (Typical) | Engineering Significance |

|---|---|---|

| VCES (Inverter & Chopper IGBT) | 1200 V | Provides a safe operating margin for applications running on 400V to 575V AC lines, accommodating voltage spikes and ensuring system robustness. |

| IC, nom / IC, max (Inverter IGBT) | 75 A / 150 A | Defines the nominal and peak current handling capability, determining the module's suitability for specific motor power ratings and overload conditions. |

| VCE(sat) (Inverter IGBT, Tj=125°C) | 2.15 V | This value represents the on-state voltage drop across the IGBT. A lower VCE(sat) translates directly to lower conduction losses, reducing the heat generated and improving overall inverter efficiency. |

| Rth(j-c) (Per IGBT) | 0.6 °C/W | This is the thermal resistance from the semiconductor junction to the case. Think of thermal resistance as the width of a highway for heat; a lower value means a wider, multi-lane highway, allowing heat to escape the die quickly and efficiently, which is critical for reliability. Mastering this concept is key to unlocking IGBT thermal performance. |

| VF (Rectifier Diode, Tj=125°C) | 1.25 V | The forward voltage drop of the input rectifier diodes. This parameter is crucial for calculating the thermal load and efficiency of the front-end power supply stage. |

Frequently Asked Questions

Your Engineering Questions Answered

1. How reliable is the solder-free pressure contact technology for long-term industrial use?

The spring-loaded pressure contact system, a hallmark of SKiiP® technology, is engineered for high reliability in demanding industrial environments. It eliminates the primary failure mode of traditional modules—solder joint fatigue caused by thermal cycling. This results in a more robust connection with a longer operational lifetime, especially in applications with frequent temperature fluctuations.

2. What level of short-circuit protection is integrated into the SKIIP23NAB126V1?

The module features integrated driver circuitry that provides protection against overcurrent and short-circuit events. The datasheet specifies a short-circuit withstand time (t_psc) of 10 µs. The integrated driver detects fault conditions and safely turns off the IGBTs, protecting both the module and the wider system from catastrophic failure.

3. What are the mounting torque requirements to ensure a proper connection with the pressure contacts?

Proper mounting is critical for pressure contact modules. While the datasheet provides the mechanical drawing, the specific application notes for the MiniSKiiP® housing should be consulted for detailed instructions on heatsink flatness, surface roughness, and the correct torque sequence for the mounting screws to ensure even pressure distribution and optimal thermal and electrical contact.

4. Can the integrated rectifier handle regenerative energy, or is the brake chopper always required?

The input bridge is a standard uncontrolled rectifier and does not support reverse power flow. For applications where the motor acts as a generator (e.g., during rapid deceleration), the DC-link voltage will rise. The integrated brake chopper is specifically included to manage this regenerative energy by switching in an external braking resistor to dissipate the excess power and maintain a stable DC bus voltage.

5. Does this module include temperature sensing?

Yes, the SKIIP23NAB126V1 includes an integrated NTC thermistor for temperature monitoring. This allows the system controller to measure the module's baseplate temperature, enabling over-temperature protection logic and facilitating active thermal management strategies to optimize performance and longevity.

A Designer's Perspective on Integrated Modules

As power electronics systems continue to evolve, the shift from discrete components to highly integrated modules like the SKIIP23NAB126V1 represents a strategic design choice. Adopting such a platform is less about individual component specifications and more about optimizing the entire engineering workflow. It allows design teams to redirect valuable resources away from the complexities of gate drive design, protection circuits, and thermal interfacing, and focus instead on higher-level system control, software development, and delivering unique application features. This modular approach not only accelerates time-to-market but also builds a more scalable and serviceable foundation for future product generations.