Industrial Applications: IGBTs in Renewable Energy, EV & Heavy Industry

In the narrative of power electronics, the headlines often belong to Wide Bandgap (WBG) materials like Silicon Carbide (SiC). However, the engineering reality of 2025 is not one of replacement, but of strategic stratification. While SiC dominates the high-frequency, space-constrained subsystems of an 800V EV, the Insulated Gate Bipolar Transistor (IGBT) remains the unrivaled workhorse for megawatt-scale power conversion.

For industrial system architects, the decision matrix has shifted from simple efficiency calculations to a balance of Short-Circuit Withstand Time (SCWT), thermal mass, and cost-per-ampere. In heavy inductive loads—from wind turbine generators to steel mill servo drives—the silicon IGBT continues to offer a ruggedness profile that newer technologies are still maturing to match.

Renewables: The Physics of Grid Stability

As wind turbines scale beyond 15MW, the power converter is no longer just a passive pipe; it is an active grid stabilizer. Modern IGBT modules (specifically IPMs) are critical here not just for their switching capabilities, but for their ability to handle the massive thermal cycling inherent in “Grid-Forming” inverter topologies.

According to NREL (National Renewable Energy Laboratory) data, the reliability of the grid interface depends heavily on the “Fault Ride-Through” capabilities of the power stage—a domain where the robust Safe Operating Area (SOA) of high-voltage IGBTs is non-negotiable.

The EV Divide: 800V SiC vs. 400V IGBT

The automotive sector presents a bifurcated market. While premium platforms migrate to SiC for range extension, the mass market—including electric buses, logistics trucks, and mid-range passenger vehicles—relies on the cost-efficiency and proven durability of IGBT traction inverters.

Industry analysis from Yole Group projects that IGBTs will retain over 60% of the EV power module market through 2026. The key innovation here is not the chip material itself, but the packaging: improved sintering and double-sided cooling are pushing silicon IGBTs to power densities previously thought impossible.

Precision in Motion: Robotics & Induction

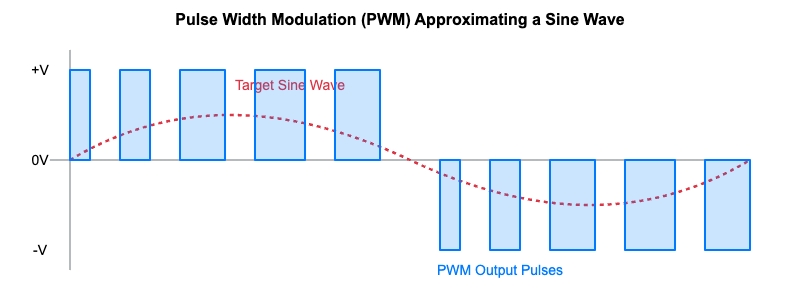

In the factory of the future, precision is power. Whether it is the robotic servo drive welding a chassis or the induction heating coil hardening a gear, the requirement is identical: exact Pulse Width Modulation (PWM) control under variable loads.

IGBTs excel in these “hard switching” environments where voltage spikes are frequent and load inertia is high. Unlike MOSFETs, which can be fragile under high-current avalanche breakdown, industrial-grade IGBTs are designed to survive the harsh electrical noise of the factory floor.

The curated articles below bridge the gap between theoretical semiconductor physics and real-world application, offering a guide to designing robust systems in an increasingly electrified world.