Content last revised on January 21, 2026

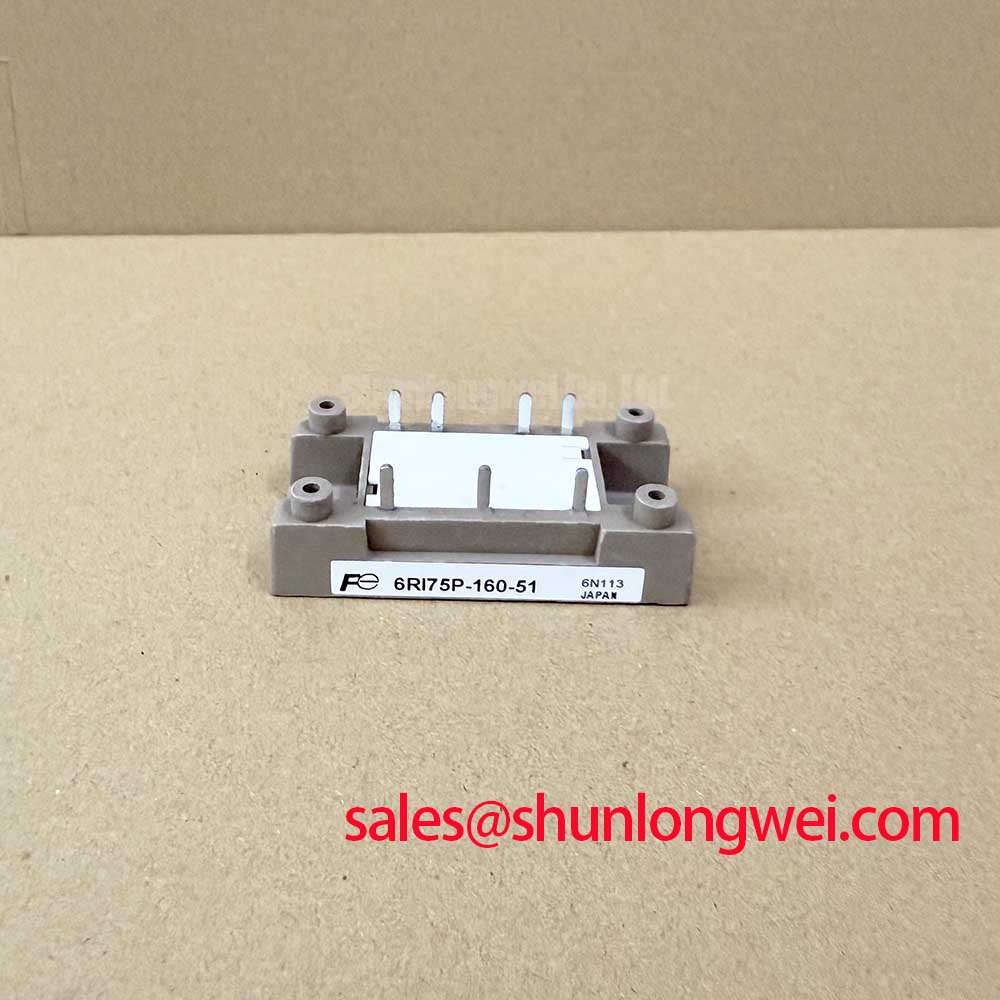

Fuji Electric 6RI75P-160-51: Engineering a Robust Three-Phase Input Stage for Industrial Power Systems

The Fuji Electric 6RI75P-160-51 is a high-reliability three-phase diode bridge rectifier module designed to provide a stable DC link for high-voltage power conversion systems. Supporting a repetitive peak reverse voltage of 1600V and a mean forward current of 75A, this module serves as the critical first line of defense in industrial power architectures. It effectively addresses the engineering challenge of managing high-voltage AC line fluctuations in 480V and 600V systems, ensuring long-term thermal stability and peak surge protection.

For engineers prioritizing thermal margin and input stage ruggedness, this 1600V rectifier module is the optimal choice for high-density power designs.

Application Scenarios & Value

Ensuring Input Stability in Industrial Variable Frequency Drives

In high-power industrial environments, the 6RI75P-160-51 is primarily utilized as the input rectifier stage for Variable Frequency Drives (VFD) and Servo Drives. Its high surge current rating (Ifsm) allows it to withstand the initial inrush current during the charging of the DC bus capacitor bank, a common point of failure in less robust designs. By integrating this module, OEMs can enhance the reliability of machinery operating on industrial motor drives, especially in regions with unstable grid conditions.

Beyond motor control, this module is an essential component in Uninterruptible Power Supplies (UPS) and high-capacity battery chargers. In these applications, the low forward voltage drop minimizes power losses, contributing to the overall system efficiency required for energy-star compliance. For systems requiring integrated switching capabilities, the related 6MBP25VAA120-51 offers an alternative power integrated approach for different stages of the circuit. More technical insights on power stages can be found in our guide on the backbone of high-efficiency power systems.

Key Parameter Overview

Decoding Technical Specifications for Enhanced System Reliability

The performance of the 6RI75P-160-51 is defined by its ability to handle significant electrical and thermal stress without degradation. The table below highlights the critical engineering benchmarks extracted from the official Fuji Electric documentation.

| Parameter | Official Rating / Value | Engineering Significance |

|---|---|---|

| Repetitive Peak Reverse Voltage (Vrrm) | 1600V | Provides a safety margin for 480V/600V AC industrial line transients. |

| Average Forward Current (Io) | 75A | High current density in a compact P-package footprint. |

| Surge Forward Current (Ifsm) | 1000A (at 60Hz) | Crucial for handling cold-start inrush currents. |

| Junction Temperature (Tj) | -40 to +150°C | Extends operational life in harsh thermal environments. |

| Isolation Voltage (Viso) | 2500V AC | Ensures safety and electromagnetic compliance in multi-module systems. |

Technical Deep Dive

Advanced Thermal Management and Material Integrity

The 6RI75P-160-51 utilizes a glass-passivated chip structure, which acts as a molecular-level shield against environmental contaminants and humidity. This passivation process is essential for maintaining the 1600V blocking capability over the module's 20-year service life. Think of this structure as a high-performance seal on a hydraulic valve; even under intense pressure, it prevents "leakage" (leakage current) that could otherwise lead to thermal runaway.

Furthermore, the internal ceramic isolation substrate is engineered for low thermal resistance (Rth). By reducing the thermal path between the diode junction and the heatsink, the module maintains a lower operating temperature. This design choice is critical for engineers looking to maximize power density without resorting to oversized cooling solutions. Understanding the balance between current and thermal management is discussed further in the core trio of module selection.

Industry Insights & Strategic Advantage

Aligning Rectification Efficiency with Modern Energy Standards

As industrial regulations shift toward mandatory energy efficiency and carbon neutrality, the role of the input rectifier has become increasingly strategic. The 6RI75P-160-51 supports these goals by reducing conduction losses. In large-scale deployments, such as Solar Inverters or massive Variable Frequency Drive arrays, a reduction in forward voltage drop by even a few millivolts translates into significant kilowatt-hour savings over the equipment's lifespan.

Strategic procurement of robust modules like the 6RI75P-160-51 reduces the Total Cost of Ownership (TCO) by minimizing downtime caused by grid surges. While the industry is seeing a rise in SiC Module technology for high-speed switching, the silicon-based diode module remains the standard for cost-effective, durable rectification. For engineers comparing these technologies, the guide on switching speed and power losses provides a deeper context.

FAQ

Common Engineering Queries Regarding the 6RI75P-160-51

How does the 1600V Vrrm rating impact the selection of surge protection components?

The 1600V rating provides a substantial buffer for standard 480V lines, where transients often exceed 1000V. This high rating allows engineers to use smaller or less aggressive MOV (Metal Oxide Varistor) protection, as the 6RI75P-160-51 can safely block these peaks without failure.

What is the primary benefit of the module's three-phase bridge configuration?

The integrated Three-Phase Bridge configuration simplifies PCB layout and mechanical assembly. It reduces the stray inductance that typically occurs when using discrete diodes, thereby improving the overall EMC (Electromagnetic Compatibility) performance of the input stage.

Does the 75A average current rating account for high-temperature operation?

The 75A rating is typically measured at a specific case temperature (Tc). In practical thermal design, engineers must apply de-rating curves based on the efficiency of the heatsink and the ambient air temperature to ensure the junction temperature stays below the 150°C limit.

Can the 6RI75P-160-51 handle the regenerative braking energy returned from a motor?

No, standard diode modules only allow uni-directional current flow. For applications involving regenerative braking, this module should be paired with an IGBT Module based braking chopper or a bi-directional converter to safely manage returned energy and protect the DC link.

As energy systems become more complex, the demand for high-voltage ruggedness continues to grow. Choosing a proven platform like the Fuji Electric 6RI75P-160-51 ensures that the core of your power conversion system is built on a foundation of reliability and efficient thermal performance.