Content last revised on January 21, 2026

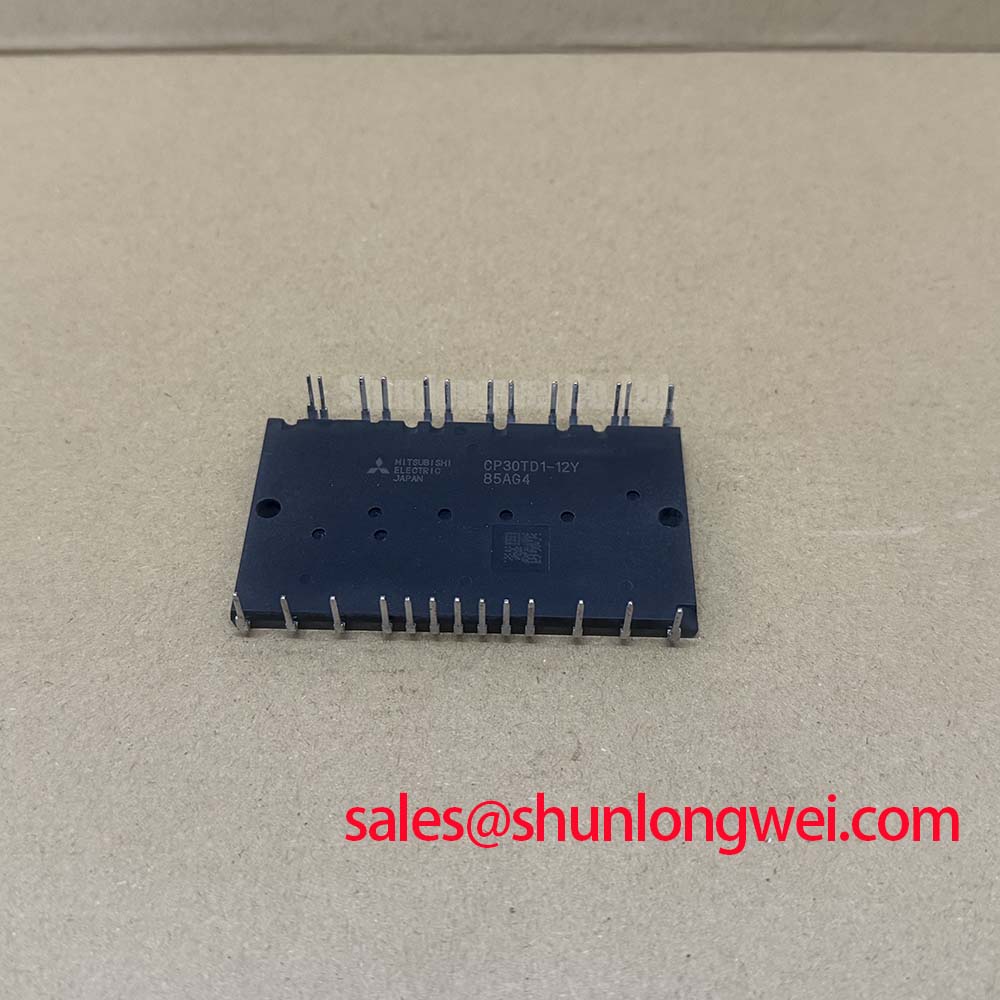

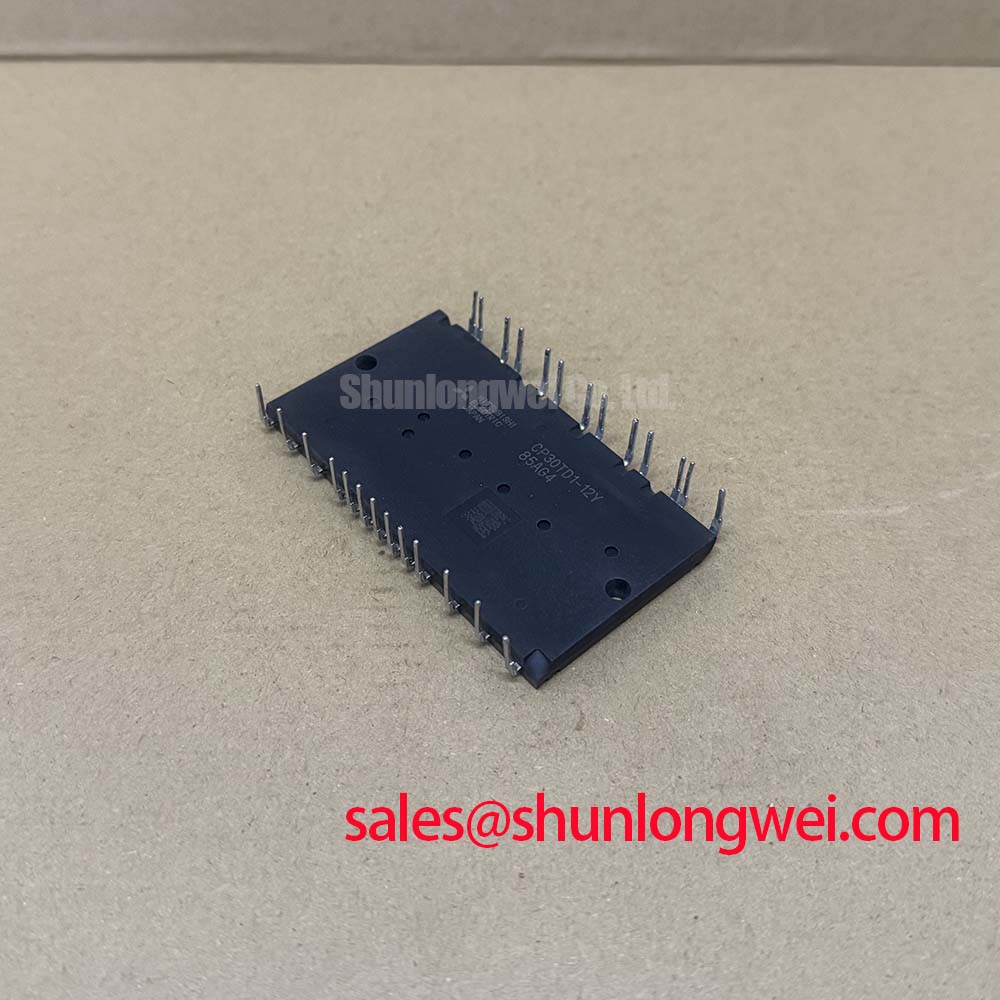

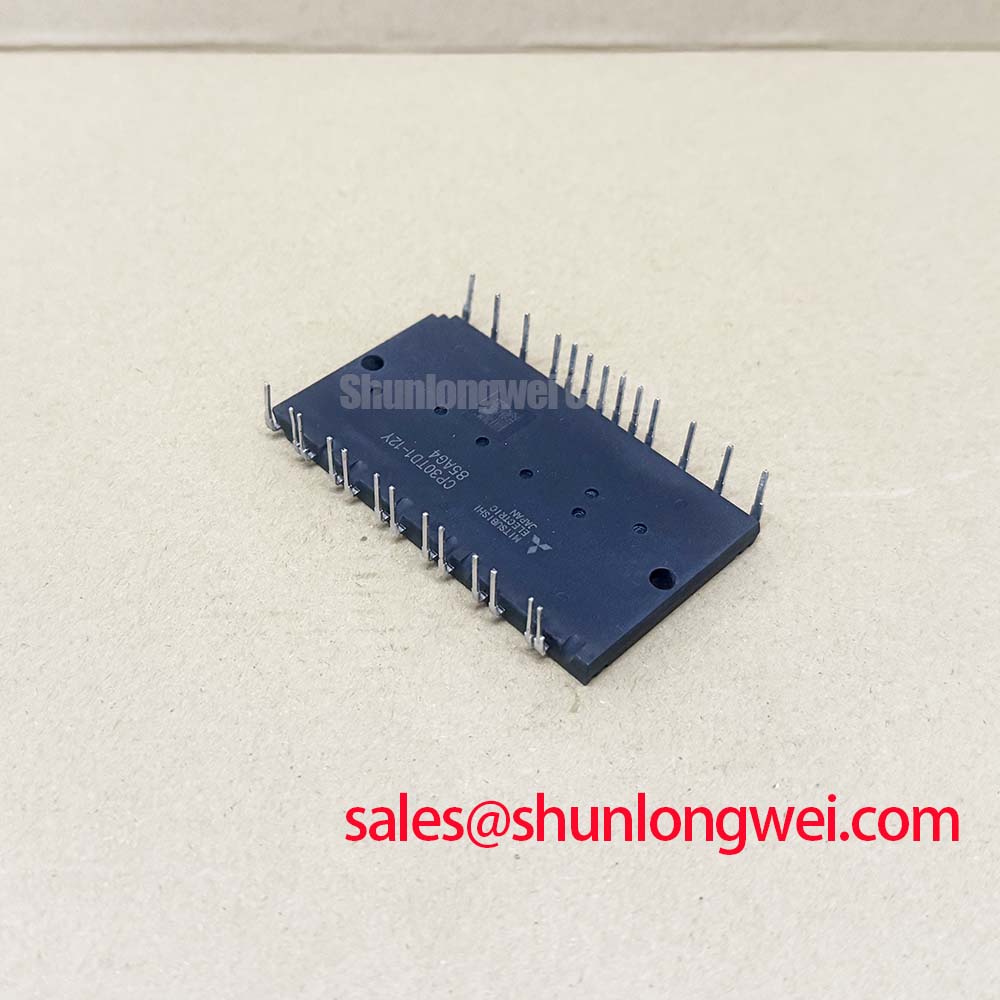

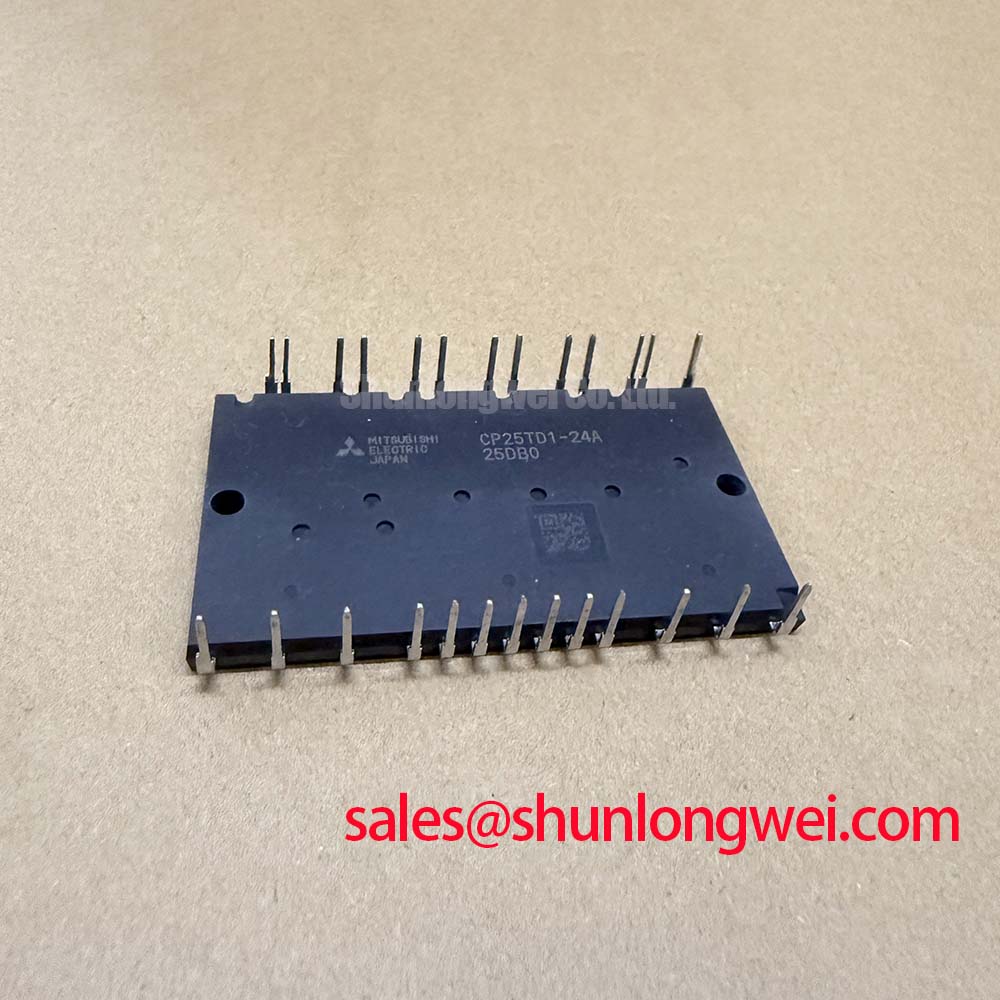

CP30TD1-12Y | 600V 30A DIP-CIB Module for Drive Integration

Streamline your compact motor drive design with the Powerex CP30TD1-12Y, an all-in-one power module engineered to reduce complexity and accelerate time-to-market. By integrating a full three-phase converter, CSTBT inverter, brake circuit, and crucial sensing features into a single low-profile package, this module provides a robust foundation for modern power control systems. It features core specifications of 600V | 30A | VCE(sat) 2.2V (typ). Key benefits include a simplified Bill of Materials and accelerated assembly. For engineers asking how to implement cost-effective phase current monitoring, the CP30TD1-12Y provides open emitter terminals, enabling direct, non-isolated feedback for sophisticated control algorithms.

Real-World Integration: Deployment Scenarios

The highly integrated nature of the Powerex CP30TD1-12Y translates directly into practical benefits across various stages of product development and deployment. Its consolidated architecture is frequently leveraged in space-constrained applications where replacing dozens of discrete components with a single module is a significant advantage. For instance, in the development of multi-axis CNC machinery or decentralized conveyor systems, the reduced PCB footprint allows for smaller, more localized motor controllers. This simplifies cabinet wiring, improves EMI performance by shortening power loops, and ultimately lowers the total cost of installation and maintenance.

In high-volume manufacturing environments, such as for advanced home appliances or automated guided vehicles (AGVs), the module's design significantly speeds up assembly. The reduction in component count and solder joints directly correlates to higher production yields and enhanced long-term reliability. What is the primary benefit of its integrated design for manufacturing? A dramatic reduction in assembly steps and potential points of failure.

Core Specifications for Simplified Design

The technical parameters of the CP30TD1-12Y are tailored to support efficient and straightforward system design. The following table highlights key specifications from the datasheet that are central to its role in simplifying power electronics development.

| Parameter | Value |

|---|---|

| Collector-Emitter Voltage (Vces) | 600V |

| Collector Current (Ic) | 30A |

| Collector-Emitter Saturation Voltage (VCE(sat)) (Tj=125°C, Ic=30A) | 2.2V (Typical) |

| Isolation Voltage (Viso, AC 1 min.) | 2500Vrms |

| NTC Thermistor R25 | 5 kΩ |

| Package Type | DIP-CIB (Dual In-line Package CIB) |

Streamlining Power Designs: Target Applications

The unique combination of integration and performance in the Powerex CP30TD1-12Y makes it a valuable component for a range of motion control and power conversion applications. Its design philosophy prioritizes reducing engineering effort and system size.

- Compact Variable Frequency Drives (VFDs): The module contains the complete power stage for small AC motor drives, including the AC-DC rectification, DC-AC inversion, and dynamic braking circuit. This makes it ideal for compact general-purpose inverters up to approximately 7.5 kW.

- Servo Drives & Robotics: In robotic arms and automated machinery, space and reliability are critical. The module’s open-emitter configuration allows for the precise current control needed in high-performance servo drives, while its small footprint enables decentralized drive architectures.

- HVAC Systems: For residential and light commercial air handlers and compressors, the CP30TD1-12Y provides a cost-effective and reliable solution for variable-speed motor control, contributing to overall system energy efficiency.

- Pump and Fan Controllers: The integrated feature set simplifies the design of controllers for industrial pumps and fans, where dependable, efficient operation is the primary requirement.

For motor drives requiring high efficiency in a compact form factor, this integrated module is the optimal choice over complex discrete component designs. The ability to mount a complete, pre-tested power stage simplifies both the design and manufacturing processes.

Engineering Questions on the CP30TD1-12Y Answered

1. What is the main advantage of the "open emitter" design in the CP30TD1-12Y?

The open-emitter configuration provides separate emitter connections for each of the lower-side IGBTs in the three-phase inverter. This allows design engineers to insert a low-cost shunt resistor in each phase leg to ground, enabling direct and independent measurement of phase currents. This is a crucial feature for implementing advanced motor control strategies like Field-Oriented Control (FOC) without the expense and complexity of isolated current transducers.

2. How does the integrated NTC thermistor simplify thermal management?

The built-in NTC thermistor provides a direct, real-time reading of the module's baseplate temperature. Think of it as a dedicated thermometer placed right next to the heat source. This eliminates the need for mounting and wiring an external sensor, which can be prone to placement errors and assembly inconsistencies. This integrated feedback allows the system controller to accurately monitor thermal stress, implement over-temperature protection, and potentially optimize fan speed, leading to a more reliable and efficient end-product. For a deeper understanding of thermal performance, explore this guide on Why Rth Matters: Unlocking IGBT Thermal Performance.

3. What is a "DIP-CIB" module, and why is this package style beneficial?

DIP-CIB stands for Dual In-line Package - Converter Inverter Brake. This package style is a low-profile, transfer-molded module with terminals arranged for easy through-hole PCB mounting. Its primary benefits are compactness and simplified assembly. The flat, isolated baseplate ensures efficient heat transfer to a heatsink, while the integrated nature of the CIB topology reduces the overall power circuit footprint, simplifying the layout process for engineers.

4. Can the CP30TD1-12Y be used for applications other than motor control?

While optimized for motor drives, its architecture is also suitable for other small-scale power conversion tasks. This includes applications like small uninterruptible power supplies (UPS), welding power sources, and specialized power supplies where a three-phase AC input needs to be converted to a controlled three-phase AC output. The key is that the application must benefit from the integrated rectifier, inverter, and brake circuit topology.

Architectural Breakdown: The All-in-One Advantage

At its core, the Powerex CP30TD1-12Y is an intelligent consolidation of three critical power system blocks into a single, thermally efficient component. This integrated architecture is the key to its value in modern power designs.

Converter, Inverter, and Brake in a Single Footprint

The module houses a three-phase diode bridge for rectifying AC line voltage, a three-phase inverter stage built with Powerex's 5th generation CSTBT™ (Carrier Stored Trench-Gate Bipolar Transistor) technology for low VCE(sat), and a dedicated brake circuit (chopper) for managing regenerative energy. This level of integration removes the need for engineers to design, source, and validate three separate power stages and their interconnections. What is the impact of CSTBT technology? It provides lower conduction losses compared to previous IGBT generations, enhancing overall drive efficiency.

Interpreting the Integrated NTC Thermistor

The integrated NTC thermistor is more than just a component; it is a direct line of communication to the module's thermal state. Its resistance changes predictably with temperature, allowing a simple voltage divider circuit connected to a microcontroller's ADC to provide continuous thermal monitoring. This data is essential for implementing protective shutdowns and for dynamic performance adjustments, ensuring the system operates within its Safe Operating Area (SOA).

Meeting Industry Demands for Compact Power Systems

The evolution of industrial automation and sophisticated electronics places increasing pressure on designers to deliver more functionality in smaller packages. The CP30TD1-12Y is a direct response to this trend. By collapsing the essential components of a motor drive into one module, it enables the development of smaller, lighter, and more power-dense equipment. This is particularly relevant in decentralized automation architectures, where intelligence and power control are moving from large, centralized cabinets to being directly integrated into machinery. This module acts as a key enabler for this shift, simplifying the design of distributed drive systems and paving the way for more modular and scalable factory automation. Further insights on IGBT technology's role can be found in our article on IGBT Modules: The Backbone of High-Efficiency Power Systems.

Data for Your Decision: A Factual Comparison

To assist in your evaluation process, this section provides a factual comparison based on published datasheet values. This data is intended to empower your engineering decisions, not to guide selection. When designing power systems, factors such as thermal design, gate drive implementation, and control strategy are equally critical.

For systems that may require a higher current rating while maintaining a similar integrated topology, the BSM50GP60 offers a 600V, 50A alternative to consider in your analysis.

A Path to More Integrated and Resilient Power Design

The trajectory of power electronics is clear: greater integration, higher efficiency, and simplified design cycles. The Powerex CP30TD1-12Y embodies this future by providing a comprehensive, pre-engineered power stage that frees design teams to focus on higher-level control and application-specific features. By adopting such integrated modules, engineering teams can not only shrink their physical designs but also reduce the intangible costs associated with sourcing, qualifying, and assembling complex discrete solutions. This strategic shift towards modular power components is foundational for creating the next generation of compact, intelligent, and reliable automated systems.