In the world of power electronics, a disruptive conversation is gaining momentum. Walk through any virtual or physical engineering forum, and you’ll hear the buzz around wide-bandgap (WBG) semiconductors. Gallium Nitride (GaN) and Silicon Carbide (SiC) are hailed as the future, promising unprecedented efficiency and power density. This inevitably leads to a critical question for design engineers and procurement managers alike: Is the era of the venerable silicon Insulated Gate Bipolar Transistor (IGBT) coming to an end? Is GaN truly the “IGBT killer” that headlines suggest?

As a field application engineer who has spent over a decade designing-in and troubleshooting power systems, I can tell you the answer isn’t a simple “yes” or “no.” The reality is far more nuanced and application-dependent. To declare the IGBT obsolete is to overlook its profound strengths and the specific engineering problems it solves so elegantly and cost-effectively. This article will cut through the hype, providing a pragmatic, application-focused analysis of where IGBTs, GaN, and SiC truly belong in 2024 and beyond. It’s not about a revolution, but an evolution—a diversification of the power electronics toolbox.

The Incumbent Champion: Understanding the IGBT’s Enduring Strengths

Before we crown a new king, we must respect the reigning champion. The IGBT is a masterpiece of semiconductor engineering—a hybrid device that combines the simple gate-drive characteristics of a MOSFET with the high-current and low-saturation-voltage capability of a bipolar transistor. This unique structure gives it a set of advantages that remain highly relevant.

The core strengths of the IGBT are:

- High Power Handling: IGBTs are built to manage immense power. Modules like the Mitsubishi CM600DX-24T can handle hundreds of amperes at voltages of 1200V and beyond, making them the default choice for applications measured in tens or hundreds of kilowatts.

- Superior Voltage Blocking: With ratings commonly available from 600V to 6.5kV, IGBTs provide the high voltage standoff capability required for direct connection to industrial power grids.

- Robustness and Reliability: Decades of manufacturing refinement have made silicon IGBTs incredibly tough. They possess a high SOA (Safe Operating Area) and excellent short-circuit withstand time, critical for surviving the harsh, unpredictable conditions of industrial environments.

- Cost-Effectiveness: When it comes to cost per ampere, especially at high power levels, the mature manufacturing process of silicon IGBTs gives them an economic advantage that WBG devices, for now, cannot match.

These characteristics have cemented the IGBT’s position in foundational applications like motor drives, utility-scale renewable energy inverters, and industrial welding systems.

The Rise of the Challengers: GaN and SiC Explained

The excitement around GaN and SiC stems from their superior material properties, specifically their “wide bandgap.” This physical characteristic allows them to sustain much higher electric fields and temperatures than silicon, which translates directly into significant performance gains.

Gallium Nitride (GaN): The High-Frequency Specialist

GaN’s most remarkable feature is its incredibly high electron mobility. This allows GaN High-Electron-Mobility Transistors (HEMTs) to switch at speeds that are an order of magnitude faster than IGBTs—well into the megahertz (MHz) range. This high switching frequency is not just for speed’s sake; it enables a dramatic reduction in the size, weight, and cost of passive components like inductors, transformers, and capacitors. The result is a system with unparalleled power density. However, GaN’s current sweet spot is in the lower-to-medium voltage range, typically below 650V.

Silicon Carbide (SiC): The High-Temperature, High-Voltage Performer

Silicon Carbide sits strategically between silicon and GaN. Its key advantages are a high breakdown electric field and excellent thermal conductivity. This allows SiC MOSFETs to block very high voltages (up to 3.3kV and beyond) while exhibiting significantly lower conduction losses (Rds(on)) than their silicon counterparts. They can also operate reliably at higher junction temperatures. SiC effectively bridges the gap, offering performance that exceeds IGBTs in efficiency-critical applications without being limited to the lower power levels of GaN. For a deep dive into SiC technology, leading manufacturers like Infineon offer extensive resources.

Head-to-Head Comparison: IGBT vs. SiC vs. GaN

To make an informed decision, engineers need to see the data side-by-side. The following table provides a practical comparison of these three technologies from a system designer’s perspective.

| Parameter | Silicon (Si) IGBT | Silicon Carbide (SiC) MOSFET | Gallium Nitride (GaN) HEMT |

|---|---|---|---|

| Voltage Range | Excellent (600V – 6.5kV) | Very Good (650V – 3.3kV+) | Moderate (100V – 650V, up to 900V emerging) |

| Power Rating | Very High (up to MW) | High (up to several hundred kW) | Low to Medium (up to ~10kW) |

| Switching Frequency | Low (< 50 kHz) | Medium to High (50 kHz – 500 kHz) | Very High (200 kHz – 2 MHz+) |

| Conduction Losses | Good (Low VCE(sat) at high current) | Excellent (Low Rds(on), low temperature dependency) | Excellent (Very low Rds(on)) |

| Switching Losses | High | Low | Very Low (minimal Qrr) |

| Operating Temperature | Good (Tj max ~150-175°C) | Excellent (Tj max > 200°C) | Very Good (Tj max ~150-175°C, system-limited) |

| Cost per Ampere (Relative) | $ (Lowest) | $$$ (High) | $$ (Medium, but system cost can be lower) |

| Maturity & Reliability | Very High (Decades of field data) | High (Rapidly maturing) | Medium (Growing rapidly, less long-term data) |

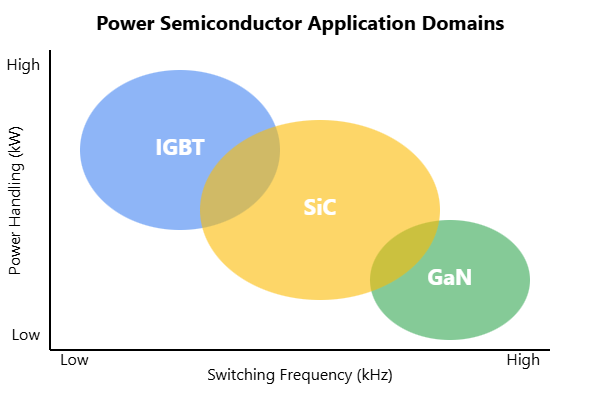

Application Sweet Spots: Where Each Technology Shines

The “best” technology is the one that best solves the engineering problem at hand. The choice is a classic trade-off between power, frequency, efficiency, and cost. Here’s a breakdown of where each device is the winning choice today.

IGBT’s Domain: High-Power, Low-to-Medium Frequency (<50 kHz)

- Applications: Industrial motor drives (>50kW), utility-scale solar and wind inverters, high-power UPS systems, welding equipment, and traction drives for rail.

- Problem: Need to control massive amounts of power (hundreds of amps, >1200V) reliably and at the lowest possible component cost. Switching frequency is secondary to raw power throughput and robustness.

- Solution: IGBT modules remain undefeated here. Their low conduction losses at high current densities and proven toughness make them the ideal workhorse. The system’s thermal and mechanical design is well-understood, minimizing development risks.

- Result: A cost-optimized, highly reliable system with a proven supply chain. The focus is on device durability rather than bleeding-edge efficiency figures that offer diminishing returns at this scale.

GaN’s Beachhead: High-Frequency, Low-to-Medium Power (< 5kW)

- Applications: High-density USB-C PD fast chargers, LiDAR systems, high-fidelity Class-D audio amplifiers, 48V data center power supplies, and satellite power systems.

- Problem: Need the smallest and lightest power supply possible. System size and weight are the primary design drivers, justifying a higher component cost.

- Solution: GaN’s ability to switch in the MHz range shrinks the required magnetics and capacitors, leading to a dramatic increase in power density.

- Result: Compact, lightweight, and efficient systems that were previously impossible with silicon technology. A 100W GaN charger can be the size of a conventional 30W silicon-based charger.

SiC’s Expanding Territory: Bridging the Gap (10kW – 150kW)

- Applications: Electric Vehicle (EV) main inverters and on-board chargers (OBC), string solar inverters, energy storage systems (ESS), and high-efficiency industrial power supplies.

- Problem: Need higher system efficiency than IGBTs can offer to extend EV range or reduce cooling requirements, but require more power and voltage than GaN can currently deliver.

- Solution: SiC MOSFETs offer a compelling blend of high-voltage capability and low switching losses. This combination reduces overall system losses, allowing for smaller heat sinks and higher power throughput in a given form factor.

- Result: An EV inverter with 2-3% higher efficiency, directly translating to longer range. A solar inverter that is smaller, lighter, and generates more energy over its lifetime. The higher cost of the SiC device is justified by the system-level benefits. For a comprehensive look at the differences, check our guide on power semiconductor selection.

The Verdict: Coexistence, Not Replacement

So, is GaN the end of the IGBT? Absolutely not. The power electronics landscape is not a zero-sum game. It is diversifying, with each technology carving out its optimal application space based on the fundamental trade-offs of Power, Frequency, and Cost.

The rise of GaN and SiC empowers engineers with more specialized tools. The key is to select the right tool for the job. You wouldn’t use a scalpel for a job that requires a sledgehammer. Similarly, you wouldn’t choose a high-frequency GaN device for a 500kW motor drive where a robust IGBT like the BSM200GB120DN2 is the perfect fit.

The future is one of coexistence and even collaboration. We are already seeing hybrid or “co-packaged” modules that pair a Silicon IGBT with a SiC diode to get the best of both worlds—the cost-effective switching of the IGBT with the superior recovery performance of the SiC diode. Technology leaders like Mitsubishi Electric continue to innovate with new generations of IGBTs that push efficiency and power density further, keeping them highly competitive.

Key Takeaways for Engineers and Purchasers

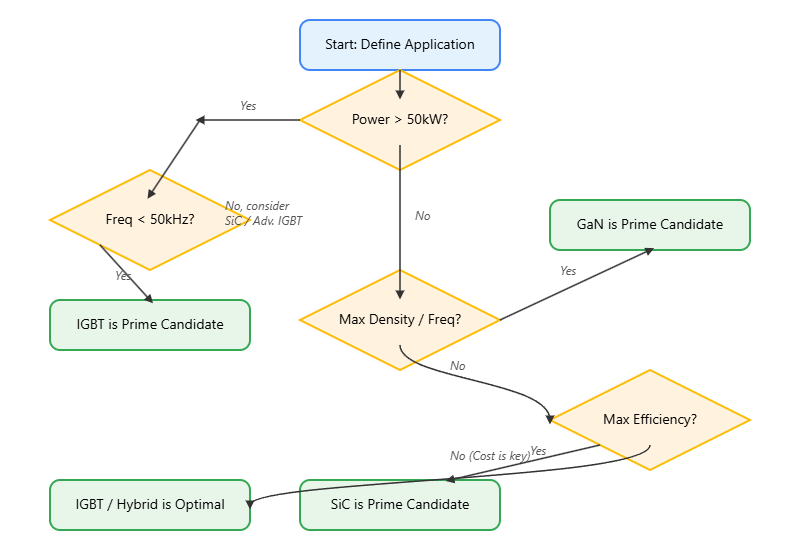

Navigating this evolving landscape requires a clear, application-centric mindset. Here are the key takeaways:

- For High Power (>50kW), Lower Frequency (<50kHz): The Si-IGBT remains the undisputed king of cost, reliability, and robustness. Don’t over-engineer your solution if an IGBT fits perfectly.

- For Maximum Power Density & Highest Frequency (>200kHz): GaN is the definitive choice for new designs in the low-to-medium power segment where size and weight are critical.

- For Premium Efficiency in the Mid-to-High Power Range: SiC is the dominant challenger to IGBTs, especially in applications like EVs and high-performance solar, where system-level efficiency gains justify the higher component cost.

The choice is no longer just between different IGBTs; it’s between entirely different semiconductor technologies. Making the right decision requires looking beyond a single datasheet parameter and considering the total system cost, performance, and reliability targets. For expert guidance in navigating these trade-offs and selecting the ideal component for your next project, explore our extensive catalog of IGBT modules or reach out to our team of experienced application engineers today.