Antimicrobial & Antiviral Screens: The Critical Role of Coated LCDs in Medical and Public Devices

In high-traffic environments like hospitals, transportation hubs, and public information kiosks, high-touch surfaces are a significant vector for pathogen transmission. The global health events of recent years have dramatically shifted our collective awareness, transforming surface hygiene from a background concern into a primary design consideration for engineers and product managers. Standard touchscreens, while essential for modern interaction, can quickly become breeding grounds for bacteria and viruses, posing a risk to public health and increasing the burden on sanitation crews. This is the critical challenge that antimicrobial and antiviral screen technology is engineered to solve.

This isn’t just about frequent cleaning; it’s about building a first line of defense directly into the hardware. Specially coated Liquid Crystal Displays (LCDs) offer a passive, continuous, and effective solution to inhibit the growth of microbes on device surfaces. For designers of medical equipment, patient check-in systems, or public transit ticketing machines, understanding this technology is no longer optional—it’s essential for creating safer, more reliable products.

The Science Behind Antimicrobial Coatings: How Do They Work?

Antimicrobial screen technology isn’t magic; it’s a sophisticated application of material science. The primary goal is to create a surface that is inherently hostile to microbial life, either by killing pathogens on contact or inhibiting their ability to reproduce. Two dominant technologies have emerged as the industry standard for industrial and medical-grade displays.

1. Silver Ion (Ag+) Technology

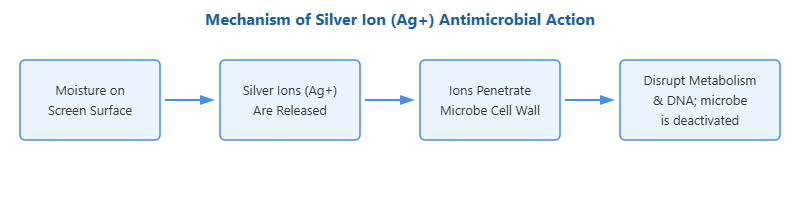

This is one of the most common and proven methods. The principle is based on the natural antimicrobial properties of silver. Here’s a step-by-step breakdown:

- Integration: A compound containing silver ions (Ag+) is embedded directly into the top layer of the glass or a durable surface coating.

- Activation: When ambient moisture from the air or from a touch is present on the screen’s surface, it triggers the release of silver ions.

- Mechanism of Action: These positively charged ions are attracted to microbes. They penetrate the cell walls of bacteria, fungi, and other microorganisms. Once inside, they wreak havoc by bonding to cellular proteins and DNA, which disrupts the microbe’s metabolism, suffocates its respiratory functions, and prevents it from replicating.

- Continuous Protection: This process is continuous and does not get “used up.” The reservoir of silver ions within the coating provides long-lasting protection throughout the display’s operational life.

The beauty of silver ion technology lies in its efficacy and safety. It is effective against a broad spectrum of bacteria, including E. coli and Staphylococcus aureus (MRSA), and is completely harmless to humans. This technology is at the heart of many high-performance displays designed for sterile environments, such as those found in the AUO Find-Display series for medical applications.

2. Photocatalytic Coatings (e.g., Titanium Dioxide – TiO₂)

A second advanced approach involves photocatalysis. This method uses a semiconductor, most commonly titanium dioxide (TiO₂), to generate powerful oxidizing agents that destroy microbes.

- The Coating: A transparent layer of TiO₂ is applied to the screen surface.

- Activation by Light: Unlike silver ions, this technology requires a light source (either ambient light or the display’s own backlight) to become active. When UV-A light photons strike the TiO₂ coating, they excite electrons, creating electron-hole pairs.

- Creating Radicals: These electron-hole pairs react with water vapor in the air to produce highly reactive hydroxyl radicals (•OH). These are potent oxidizing agents.

- Destroying Microbes: The hydroxyl radicals attack any organic matter on the surface—including bacteria and viruses—by breaking down their cellular structures into harmless water and carbon dioxide.

While extremely effective, the reliance on a light source is a key consideration. This technology is ideal for well-lit indoor environments or outdoor kiosks where UV exposure is guaranteed. You can learn more about the fundamental display technology that these coatings protect in this guide on TFT-LCD screens.

Comparative Analysis: Standard vs. Antimicrobial LCDs

When specifying a display for a public-facing or medical device, the differences between a standard screen and one with an antimicrobial coating are stark. The choice impacts not only hygiene but also long-term reliability and total cost of ownership.

| Feature | Standard Industrial LCD | Antimicrobial/Antiviral Coated LCD |

|---|---|---|

| Surface Hygiene | Relies entirely on external cleaning. Surface can harbor and spread pathogens between cleanings. | Provides continuous, passive inhibition of microbial growth (typically >99% reduction). Reduces reliance on frequent, harsh chemical cleaning. |

| Durability & Chemical Resistance | Standard surface hardness. Susceptible to damage from abrasive or harsh chemical cleaners over time. | Often features enhanced hardness (e.g., >7H pencil hardness) and oleophobic properties. Engineered to withstand repeated cleaning with common hospital-grade disinfectants. |

| Optical Performance | High optical clarity and transmittance are standard. | High-quality coatings have negligible impact (<1% loss) on transmittance, color accuracy, or viewing angles. Poorly applied coatings can cause haziness. |

| Initial Cost | Lower upfront investment. | Higher initial cost due to specialized materials and manufacturing processes (typically 15-30% more). |

| Total Cost of Ownership (TCO) | Higher TCO due to increased cleaning labor, cost of consumables, and potential downtime for sanitation. | Lower long-term TCO by reducing cleaning frequency, enhancing device longevity, and mitigating health risks. |

| Ideal Applications | Controlled industrial settings, personal devices, environments with low public interaction. | Medical patient monitors, hospital check-in kiosks, public transit systems, restaurant point-of-sale (POS), and any shared HMI. |

Application Case Study: Upgrading a Hospital’s Patient Check-in Kiosks

Problem: A large urban hospital network was facing a dual challenge: rising rates of hospital-acquired infections (HAIs) linked to high-touch surfaces and increasing operational costs tied to their stringent 24/7 cleaning protocols for patient check-in kiosks and bedside monitors.

Solution: The hospital’s engineering department, in collaboration with a device manufacturer, decided to retrofit 250 kiosks with industrial-grade 12.1-inch PCAP touchscreens featuring an integrated silver-ion antimicrobial coating. The chosen displays, similar in specification to the robust G121XCE-L01, were validated to meet ISO 22196 standards for antibacterial efficacy. The coating was bonded at a molecular level, ensuring it would not wear off from cleaning or heavy use.

Result:

- Quantifiable Hygiene Improvement: ATP swab tests conducted over a six-month period showed a sustained 99.9% reduction in the microbial load on the screen surfaces compared to the previous non-coated displays.

- Operational Efficiency: The reduced need for immediate, reactive cleaning of the touchscreens allowed the environmental services staff to be re-tasked, resulting in an estimated 18% increase in overall staff efficiency.

- Enhanced Patient Safety & Confidence: The hospital prominently communicated the technology upgrade to patients, significantly boosting their confidence in the facility’s infection control measures. This initiative contributed to a measurable decrease in contact-transmission HAIs.

A Practical Checklist for Selecting the Right Antimicrobial Display

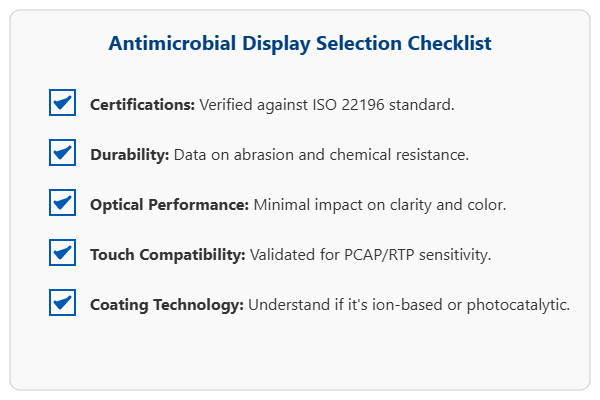

Choosing the correct display is a critical engineering decision. A simple “antimicrobial” label isn’t enough. Use this checklist to guide your selection process and ensure you are specifying a truly effective and durable solution.

- Verify Certifications: Is the display certified under ISO 22196? This is the international standard for measuring antibacterial activity on non-porous surfaces. Demand test data from the manufacturer.

- Assess Coating Durability: Ask for data on the coating’s resistance to abrasion. How many cleaning cycles with common disinfectants (e.g., isopropyl alcohol, bleach solutions) can it withstand before performance degrades? A robust coating should last the lifetime of the product. Our guide on industrial display maintenance offers further insights into safe cleaning practices.

- Evaluate Optical Clarity: Request a sample or specification sheet detailing the coating’s impact on light transmittance, haze, and color gamut. For medical imaging or high-fidelity user interfaces, optical performance is non-negotiable. Displays with IPS (In-Plane Switching) technology are often preferred for their superior viewing angles and color consistency, making it even more crucial that the coating doesn’t compromise these features.

- Confirm Touchscreen Compatibility: Ensure the antimicrobial coating is fully compatible with the specified touch technology, particularly Projected Capacitive (PCAP) touch. The coating must not interfere with the sensitivity or accuracy of touch detection, even with gloved hands.

- Consider the Entire System: The display is just one part. Ensure that the bezel, housing, and any physical buttons are also designed with hygiene in mind, either using similar antimicrobial materials or by having a seamless, easy-to-clean design.

Conclusion: A Non-Negotiable Feature for Modern Public Interfaces

Antimicrobial and antiviral screen technology has transitioned from a niche, value-add feature to a core requirement for a vast range of applications. For engineers and procurement managers working on devices for the medical, public transit, or food service industries, integrating these advanced displays is a direct investment in public health, user confidence, and long-term product viability. By providing a constant, passive barrier against pathogens, these screens reduce operational burdens and mitigate significant health risks.

As you design your next HMI or public kiosk, look beyond the resolution and brightness. In today’s world, the unseen protection offered by a high-quality antimicrobial coating is one of the most valuable features you can provide. Explore our range of durable industrial LCD solutions to find a display that delivers both exceptional performance and peace of mind.