Smooth Rides, Silent Operation: The Critical Role of IGBTs in Modern Elevator Traction Control

The Passenger Experience Challenge: Why Jerks and Jolts are Unacceptable in Modern Elevators

Step into a modern high-rise building, and the elevator ride is often something you barely notice. It’s smooth, quiet, and stops with uncanny precision, the doors opening to a floor that’s perfectly level with the car. This seamless experience is a hallmark of modern engineering, but it’s not accidental. Contrast this with an older elevator: the sudden lurch on startup, the noticeable “clunk” as it changes speed, and the slight but jarring step up or down when you exit. These imperfections are more than minor annoyances; they directly impact passenger perception of a building’s quality and safety.

For facility managers and building owners, these issues translate into tangible problems. A jerky ride can be unsettling for passengers, particularly the elderly or those with mobility challenges. Imprecise leveling is a trip hazard and a compliance issue under accessibility regulations. Furthermore, audible motor whines and mechanical vibrations create a sense of unease and suggest poor maintenance. At the core of this difference between a subpar ride and a premium experience lies the elevator’s motor control system, specifically the Variable Frequency Drive (VFD), and the power semiconductor that acts as its beating heart: the Insulated Gate Bipolar Transistor (IGBT).

The Heart of the Elevator Drive: Understanding the VFD and the IGBT’s Role

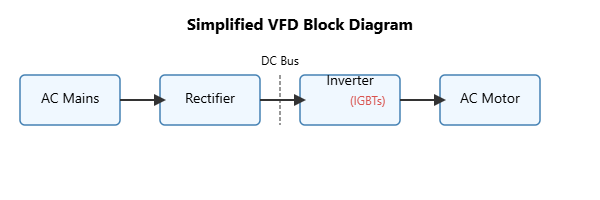

The magic of a smooth elevator ride begins with the ability to precisely control the speed and torque of the electric traction motor that hoists the car. This is the job of the Variable Frequency Drive (VFD), a sophisticated piece of power electronics that acts as the brain and muscle of the motor system.

What is a Variable Frequency Drive (VFD) in an Elevator?

In simple terms, a Variable Frequency Drive takes the standard, fixed-frequency AC power from the building’s electrical grid and converts it into a variable-frequency, variable-voltage AC output. By meticulously adjusting the frequency of the power supplied to the traction motor, the VFD can control its speed with incredible accuracy—from a slow, steady creep for leveling to a rapid, smooth ascent in a high-rise express elevator. This control is impossible with older systems that simply switch the motor on or off.

The IGBT as the Master Switch

The component within the VFD that makes this precise conversion possible is the IGBT module. An IGBT is a high-power, high-speed semiconductor switch. Inside the VFD’s inverter stage, a set of six IGBTs (for a standard three-phase motor) work in a coordinated ballet, switching on and off thousands of times per second. This technique is known as Pulse Width Modulation (PWM).

Think of it like this: the IGBTs are not simply opening and closing a floodgate. They are like a series of incredibly fast, precise digital faucets. By varying how long each “faucet” is open within a microsecond-long cycle (the “pulse width”), they chop up the steady DC voltage from the VFD’s rectifier and sculpt it into a near-perfect AC sine wave of any desired frequency and voltage. The higher the switching frequency of the IGBTs, the smoother and more perfect this synthesized sine wave becomes, resulting in finer motor control and less noise.

How IGBTs Directly Impact Elevator Performance

The theoretical precision of PWM becomes a tangible reality in the elevator car. Every aspect of a smooth ride—from acceleration to stopping—is a direct result of how well the IGBTs are performing their high-speed switching duties.

Achieving Seamless Acceleration and Deceleration

A sudden start or stop is perceived by the human body as a “jerk.” Modern VFDs use IGBTs to implement an “S-curve” acceleration and deceleration profile. Instead of ramping up speed linearly (which creates a jolt at the beginning and end), the rate of acceleration itself is gradually increased and then decreased. This creates a seamlessly smooth transition from stationary to full speed and back again, which is only possible with the continuous and fine-tuned torque control provided by fast-switching IGBTs.

Ensuring Pinpoint Leveling Accuracy

Perhaps the most critical safety feature is perfect floor leveling. An IGBT-controlled VFD can maintain precise torque on the motor even at near-zero speed. This allows the elevator to slow down and “creep” to the floor level with millimeter accuracy before the mechanical brake engages. This not only prevents trip hazards but also reduces wear and tear on the brake system, which is now used for holding rather than for stopping the car.

Reducing Acoustic Noise for a Quieter Ride

The audible “whine” from older elevator motors is often caused by the magnetic vibrations (magnetostriction) resulting from the imperfect waveforms created by slower switching components. High-quality IGBTs can switch at frequencies well above the range of human hearing (e.g., >16 kHz). This pushes the primary switching noise out of the audible spectrum, resulting in a motor and drive system that is virtually silent, dramatically improving the passenger experience.

Boosting Energy Efficiency

Modern elevators are increasingly designed with regenerative capabilities. During deceleration or when a lightly loaded car is going up (or a heavily loaded car is coming down), the motor acts as a generator. A robust, efficient IGBT-based inverter can capture this kinetic energy, convert it back into clean AC power, and feed it back into the building’s grid. The low switching and conduction losses of advanced IGBTs like those using Mitsubishi’s CSTBT™ technology are crucial for maximizing the amount of energy recovered in this process.

Key Selection Criteria for IGBT Modules in Elevator Applications

For engineers designing or maintaining elevator VFDs, choosing the right IGBT module is a critical decision that balances performance, cost, and long-term reliability. It’s not just about the headline voltage and current ratings.

Critical Electrical and Thermal Parameters

The devil is in the details of the datasheet. An ideal IGBT for an elevator drive must offer a carefully engineered compromise between several competing parameters.

| Parameter | Importance in Elevator Applications | Why It Matters |

|---|---|---|

| Collector-Emitter Saturation Voltage (VCE(sat)) | High | A lower VCE(sat) means lower conduction losses when the IGBT is on. This is critical for efficiency when the elevator is running at a constant speed, reducing heat generation and energy consumption. |

| Switching Losses (Eon, Eoff) | Very High | These losses occur during the turn-on and turn-off transitions. Since elevator VFDs use high-frequency PWM, these losses can be significant. Low switching losses reduce heat, improve overall efficiency, and allow for higher PWM frequencies for quieter operation. |

| Thermal Resistance (Rth(j-c)) | Very High | This value indicates how effectively heat can be transferred from the IGBT junction to the case (and then to the heatsink). A lower thermal resistance is essential for keeping the chip cool, which directly impacts reliability and lifespan. |

| Short-Circuit Withstand Time | Critical | This defines how long the IGBT can survive a direct short-circuit condition. In motor drives, faults can occur. A robust withstand time (typically 5-10 µs) is a crucial safety feature that prevents catastrophic module failure. |

Reliability and Durability Considerations

An elevator in a busy commercial building may perform hundreds or even thousands of start/stop cycles per day. This operational profile puts unique stress on the power module.

- Power Cycling Capability: Each start/stop cycle causes a temperature swing within the IGBT module. This leads to mechanical stress on the internal wire bonds and solder layers. Modules with superior power cycling capability, often achieved through advanced materials and manufacturing processes, are essential for long-term reliability in this high-cycle application.

- Robust Packaging: The module’s physical construction must be able to withstand mechanical vibrations from the motor and building, while ensuring excellent thermal contact with the heatsink.

Brand and Technology Spotlight

Leading manufacturers have developed specific technologies to meet these demands. For instance, Infineon’s TRENCHSTOP™ IGBTs are engineered to provide an excellent trade-off between low VCE(sat) and minimal switching losses, making them highly suitable for drive applications. Seeking modules from reputable brands like Mitsubishi, Infineon, or Fuji Electric ensures you are getting components that have been tested and proven in demanding, real-world conditions.

Case Study: Troubleshooting and Upgrading an Elevator Drive System

- Problem: A 15-year-old commercial office building was experiencing an increase in passenger complaints about jerky rides and frequent, intermittent shutdowns of one of its main elevators. Maintenance logs showed a pattern of “inverter fault” errors with no clear cause.

- Analysis: A specialized engineering team was brought in to inspect the aging VFD. Using an oscilloscope and a thermal camera, they found that the original IGBT modules were exhibiting inconsistent switching times and were running significantly hotter than specified. Years of thermal cycling had degraded the internal structure, leading to increased VCE(sat) and unreliable performance that was triggering the drive’s protection circuits.

- Solution: The decision was made to perform a targeted upgrade. The old modules were replaced with a modern equivalent, the Mitsubishi **CM300DY-24H**. This module offered significantly lower VCE(sat) and faster, more efficient switching characteristics within the same package footprint. The VFD’s control parameters, including the PWM frequency and S-curve profile, were then re-tuned to optimize performance with the new, superior components.

- Result:

- Immediate Ride Quality Improvement: Passenger complaints ceased. The ride became exceptionally smooth and virtually silent.

- Enhanced Safety & Reliability: Pinpoint floor leveling was restored. In the six months following the upgrade, unscheduled downtime related to inverter faults was reduced by 95%.

- Quantifiable Energy Savings: A post-upgrade analysis revealed that the elevator motor’s energy consumption had decreased by approximately 12%, a direct result of the higher inverter efficiency and more effective regenerative braking.

Future Trends: The Evolution of Power Electronics in Vertical Transportation

The quest for efficiency and performance continues. While advanced silicon IGBTs, like those detailed in this Infineon application note, will remain the cost-effective workhorse for the vast majority of commercial elevators, new technologies are on the horizon. For premium, high-speed applications, wide-bandgap semiconductors like Silicon Carbide (SiC) are emerging. SiC offers even lower losses and higher temperature operation, but currently at a significant cost premium. You can learn more about this in our technology showdown, SiC vs. IGBT. The trend towards intelligent power modules (IPMs), which co-package the IGBTs with their gate drivers and protection circuits, will also continue to simplify VFD design and improve reliability.

Your Checklist for Success: Key Takeaways

The smooth, silent, and safe operation of a modern elevator is not magic—it’s a testament to precision-engineered power electronics. The IGBT module is at the very center of this performance. When designing, specifying, or servicing an elevator drive system, remember these key points:

- The quality of the passenger ride experience is directly linked to the performance of the VFD and its core IGBTs.

- Precise PWM control, enabled by fast and efficient IGBTs, is the foundation for smooth S-curve motion, accurate floor leveling, and ultra-quiet operation.

- When selecting an IGBT, look beyond basic ratings. A balanced profile of low VCE(sat), low switching losses (Eon/Eoff), and excellent thermal resistance (Rth) is crucial.

- For elevator applications, prioritize modules with a proven high power cycling capability to ensure long-term reliability under thousands of daily start/stop cycles.

- Partnering with a supplier who understands these nuances can make all the difference. For expert advice and access to a comprehensive portfolio of industry-leading components, explore our range of **IGBT modules** or contact our engineering team today.